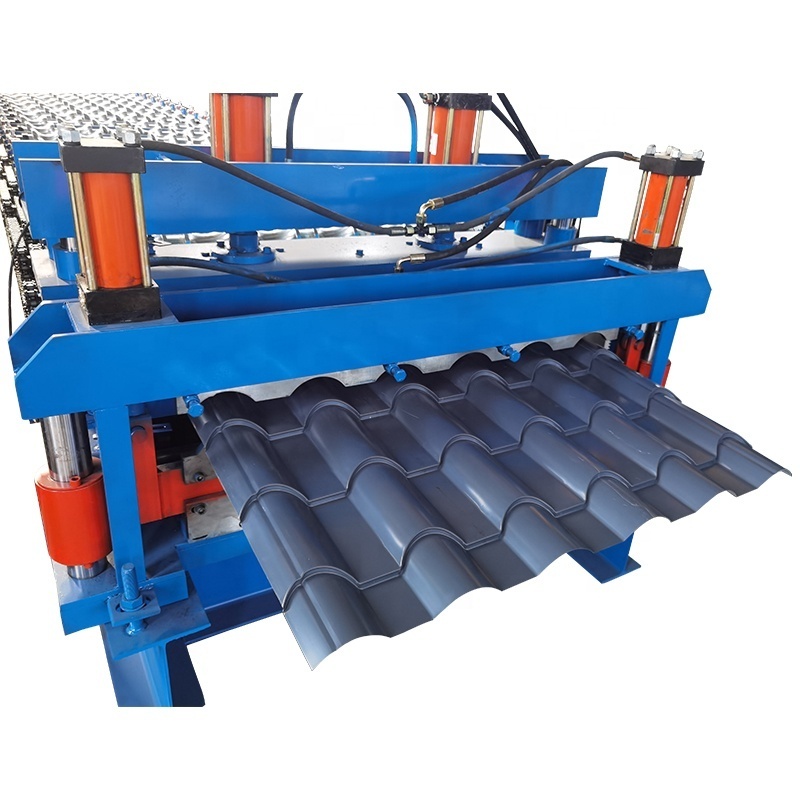

In order to get high quality product, our machine adopts welded steel frame structure, AC frequency conversion motor reducer

drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

Roller chrome coated thickness: 0.05 mm.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3

-

Weight:

-

8 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

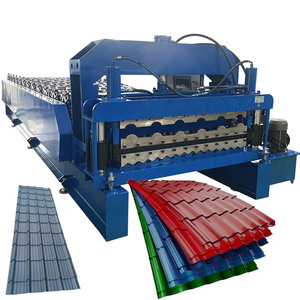

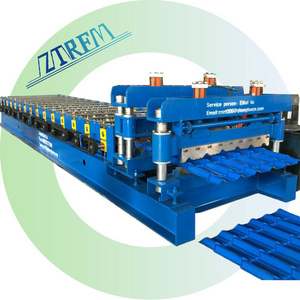

Double Layer roll forming machine

-

Usage:

-

Roof Panel

-

Color:

-

Client's Request

-

Control system:

-

PLC

-

Raw material:

-

Colored Steel

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# St

-

Cutting blade material:

-

Cr 12 Mov

-

Plc:

-

branded

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3

-

Weight:

-

8 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Double Layer roll forming machine

-

Usage:

-

Roof Panel

-

Color:

-

Client's Request

-

Control system:

-

PLC

-

Raw material:

-

Colored Steel

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# St

-

Cutting blade material:

-

Cr 12 Mov

-

Plc:

-

branded

Product Description

GLAZED STEEL TILEROLL FORMING MACHINE

The glazed tile roll forming machine is a vital piece of equipment used in the construction industry for manufacturing high-quality glazed tiles. This machine is designed to produce tiles with a smooth and glossy surface, adding aesthetic appeal to buildings. In this article, we will explore the features, benefits, and applications of the glazed tile roll forming machine.

*can be customized*

Customization

The machine allows for easy customization of tile designs, enabling manufacturers to meet the diverse demands of customers.

Durability

The glazed tile roll forming machine is built with high-quality materials, making it highly durable and resistant to wear and tear.

Low Maintenance

High-Quality Output

Advantages of Xinbo Metal Glazed Tile Machine:

1: The glazed tiles produced are durable, beautiful in appearance, waterproof and corrosion-resistant.

2: The production operation is simple, the whole process of automatic production is controlled by the PLC computer system, which greatly reduces the labor cost and can realize rapid realization.

3: The selected roller assembly is steel plated with hard chrome, which is durable and helpful for long-term use and maintenance.

4: The PLC computer control system is all precision electronic components, which can ensure the precise operation of the machine.

5: Xinbo has more than 10 years of experience in the field of metal forming machines, ensuring that customers can buy the highest quality product machines with the least money. In addition, customized services can also be provided according to the required drawings.

Detailed Images

Rollers

Hydraulic Station

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function.The system includes a set of hydraulic tank, a set of a Gear Pump, two hydraulic pipes.and two sets of Solenoid Valves.

Power of The Pump:4kw

Hydraulic oil :40#

Power of The Pump:4kw

Hydraulic oil :40#

Certification

Exhibition

Hot Searches