Automatic ready to eat meal packaging machine vacuum packed ready meal packaging machine

-

Transport Package:

-

Export wooden cases

-

Specification:

-

4570x1470x1870mm

-

Trademark:

-

HENGHANG

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

China

-

After-sales Service:

-

Remote guidance

-

Warranty:

-

1 year

-

Type:

-

Piston Filling Machine Volumetric Filling Machine Weighing-type Filling Machine Count Filling Machine

-

Automatic Grade:

-

Automatic Fully Automatic Semi-Automatic

-

Material Type:

-

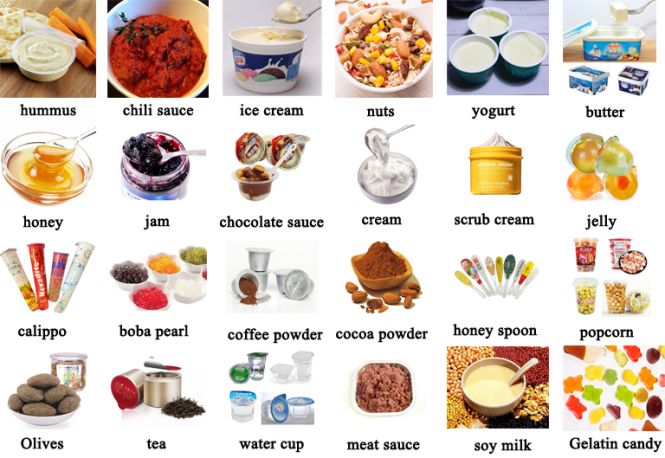

Liquid Granular Powder Paste Solid Mucilage

-

Filling Valve Head:

-

Multi-Head Single-Head

-

Feed Cylinder Structure:

-

Multi-Room Feeding Single-Room Feeding Dual-Chamber Feeding

-

Dosing Device:

-

Capacity Cup Plunger Rotor

-

Filling Principle:

-

Pressure Atmospheric Pressure Vacuum Negative Pressure Back Pressure

-

Packaging Container Lifting Structure:

-

Pneumatic Lifting Chute Lifting Chute Pneumatic Combination Lifting

-

Structure:

-

Rotary Linear

-

Packaging:

-

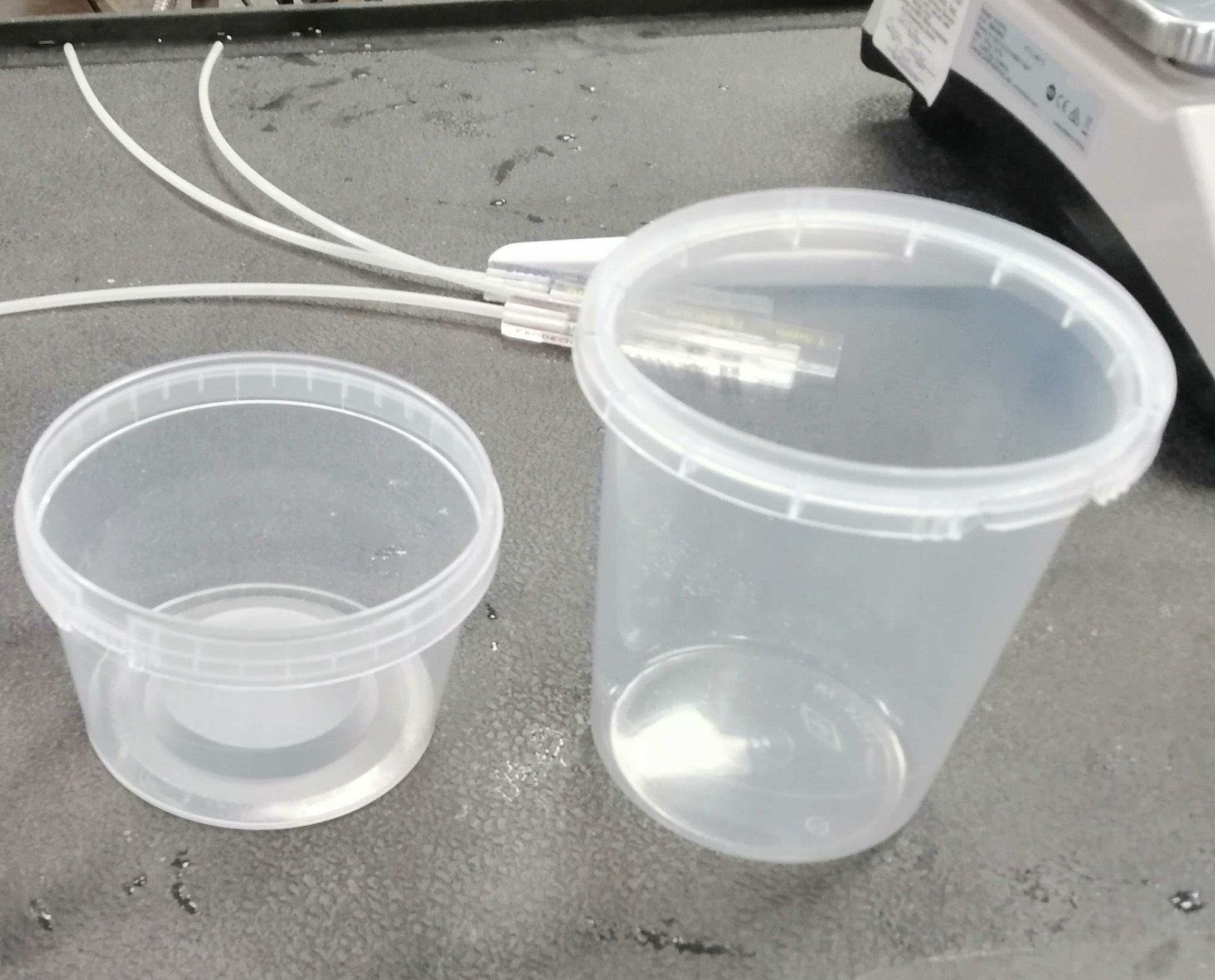

Bottle Barrel Box

-

Packaging Material:

-

Plastic Composite Materials Metal

-

Whether CIP cleaning:

-

yes

-

Payment:

-

T/T Paypal

-

Export Port:

-

Shanghai /Ningbo

-

Output:

-

40/hr

-

Model NO:

-

RCC-2000-40

Quick Details

-

Whether CIP cleaning:

-

yes

Wenzhou Henghang Machinery Technology Co., Ltd. is a company with a team of over ten years of in the field of automated filling and capping equipment. As a high-tech enterprise specializing in the design and manufacture of automatic packaging equipment and accessories, we have accumulated experience through relentless efforts. Our company is based on the production and research of filling and capping machines, nipple bag capping machines, and other food and beverage chemical products. The company adheres to the business philosophy of quality leadership and customer supremacy, combining independent research and development. We have successively developed a series fully automatic pneumatic (electric) packaging and capping machines, cups, boxes, bowls, bottles, bags, and other irregular containers: bottle handling, cup, filling, lid handling, lid placement, pressing, capping, film covering, sealing, film cutting, coding, labeling, vacuum drawing, gas filling, heating cooling, drying, and other process automation production line equipment. We have designed and customized beverage production lines and food production lines for our customers. Our products integrate, electronic, numerical control, and microcomputer technologies, and can be widely used in the packaging of various products in the food, beverage, daily chemical, pharmaceutical and pesticide industries. We provide one-stop turnkey engineering services including process design, factory construction guidance, mechanical manufacturing, installation and commissioning, after-sales service, training, and technical recipes. Corporate Purpose Since its establishment, the company has adhered to the belief of "integrity" first, relied on the direction technological progress, and insisted on the policy of "innovation" to open up the market. We strengthen internal management, adhere to the business purpose of "customer and market-oriented", continuously improve the technological innovation level of products, and create greater economic benefits and market competitiveness for customers. Looking to the future, our company will to innovate and develop new generations of high-tech content technology products. We will continue to make progress and contribute to the machinery industry in our country. We will work in hand with new and old customers with a sincere attitude to create a prosperous future.

1.BRIEF INTRODCUTION

BG series inline tray sealing machine (intermittent motion) can be customized to pack various liquid, paste, granular and powder products into containers of various sizes and shapes. The machine can be used in a variety of applications in the food industry, such as honey, jam, chili sauce, pet food (such as cat food, dog food), instant takeaway, etc.

According to the required output, the BG series linear filling and sealing machine can be designed for 2 trays, 4 trays, 6 trays or more each time.

This series of machines can be individually customized for filling or sealing functions, and vacuum inflatable packaging can be customized according to requirements. Suitable for packaging of different products.

2. Customized packaging machine equipment structure:

1. Frame part:

1.1. The entire machine is welded with high 304# stainless steel square tubes.

1.2. The motor box head frame plate is welded with 30mm thick A3 steel plate, the exterior is covered with stainless steel.

1.3. There are movable directional wheels and positioning devices in contact with the ground.

1.4. The entire frame is welded as a single unit.

2. Mold part:

2.1. The mold is designed for four outputs.

2.2. The mold is according to the customer's sample, and the mold arrangement is based on the customer's sample.

2.3. Corrosion-resistant and acid-alkali molds are used.

3. Automatic film feeding system:

3.1. The film feeding shaft uses thick-walled stainless steel pipe, and a quick-release top cone is used;

3.2. The film feeding shaft can be fine-tuned axially;

3.3. The other end of the film feeding shaft a supporting structure.

4. Sealing part:

4.1. Constant temperature (smart temperature control) hot pressing sealing is used, and the sealing pressure is; 4.2. Two-time sealing, the first pre-sealing, the second additional sealing, to ensure a firmer seal;

5. Cutting:

51 The knife is serrated, and the cup cover film has an easy-tear tab (customized according to customer requirements), the knife material is manganese steel material, and it undergoes special treatment (high hardness); 5.2 A straightening rod and universal joint are used to accurately align the template;

5.3 mechanical cup is dropped onto the conveyor belt;

6. Cup dispensing system:

6.1. Uses mechanical automatic cup dispensing, high efficiency, low maintenance cost.

7. Transmission:

7.1. Composed of motor, reducer, and template, high-performance reducer;

7.2. The chain uses GB/T1243 standard 10A-1 or 12A-1 short pitch precision roller stainless steel thick chain;

7.3. Stainless steel chain and green PE rail. Transmission translation, small impact force, accurate positioning.

8.Support CIP cleaning

1. Shipping and transportation requirements: Ship to local logistics, air transport, wooden box packaging (not recyclable by the supplier). 2. Equipment of the filling and sealing machine

2. Performance: Automatic cup placement (meets automatic feeding standards), automatic filling, automatic film placement, automatic photoelectric pattern alignment, automatic date, automatic sealing one, automatic sealing two, automatic film cutting, automatic finished product output.

3.TECHNICAL PARAMETER

| BG-4 | Inline Type Automatic Sealing Machine |

| Production capacity | 2000-2400 trays/hour |

| Filling volume | Can be customized |

| Voltage | 380V/50Hz.220v/60HZ |

| Air consumption | 0.8㎥/min |

| Power | 4kw |

| Dimension | 4570x1470x1870mm |

| Weight | 1500kg |