- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongsan

-

Voltage:

-

380v50hz 3 phase

-

Dimension(L*W*H):

-

25*2.5*2.3

-

Power (kW):

-

75

-

Weight:

-

4000

-

Name:

-

HDPE double wall corrugated pipe machine

-

Raw material:

-

PP HDPE

-

Final product:

-

Double wall corrugated pipe

-

Extruder type:

-

single screw extruder

-

Extruder model:

-

SJ90/30 +SJ75/30

-

Capacity:

-

120- 160 KG/H

-

Production speed:

-

3-5m/min

-

Pipe diameter:

-

11 mm-250mm

-

Motor:

-

Siemens Beide

-

Inventer:

-

ABB

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

1440 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tongsan

-

Voltage:

-

380v50hz 3 phase

-

Dimension(L*W*H):

-

25*2.5*2.3

-

Power (kW):

-

75

-

Weight:

-

4000

-

Name:

-

HDPE double wall corrugated pipe machine

-

Raw material:

-

PP HDPE

-

Final product:

-

Double wall corrugated pipe

-

Extruder type:

-

single screw extruder

-

Extruder model:

-

SJ90/30 +SJ75/30

-

Capacity:

-

120- 160 KG/H

-

Production speed:

-

3-5m/min

-

Pipe diameter:

-

11 mm-250mm

-

Motor:

-

Siemens Beide

-

Inventer:

-

ABB

-

Certification:

-

CE

Product Description

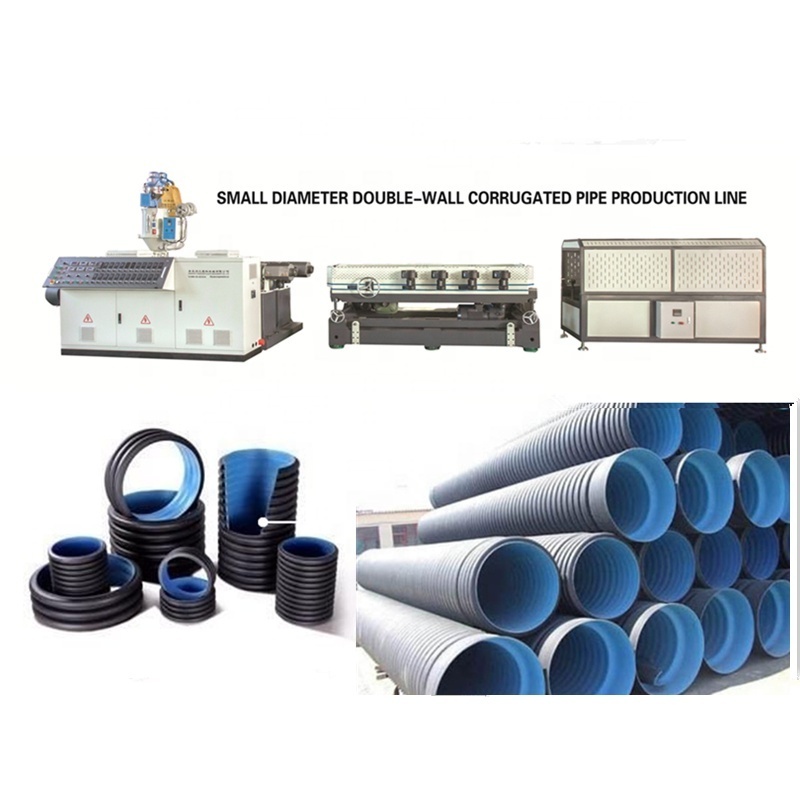

PE/HDPE/PVC double wall corrugated pipe extrusion line adopts extruding and forming process, it has the featuresof reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessories installed,and quality reliable.

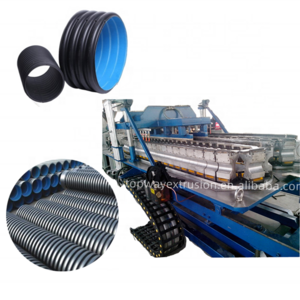

SBWG series double - wall corrugated pipe production line can continuously produce HDPE double - wall corrugated pipe and this line can achieve on-line belling.The machine has the function of automatic de-molding when power is off.The extruder adopt high-efficiency screw, the die head adopts double-layer spiral structure, mold die and core die being nitrided .The forming machine adopts vacuum forming type, equipped with automatic lubrication system.Forming mold is made of aluminiumalloy, adopt water cooling type.The pipe can be cut by on-line cutting machine automatically.

Our double wall corrugated pipe machine can use the aluminum module which with water cooling can vacuum cooling for high speed.We have professional designers and sophisticated processing machine to ensure the accuracy of the mold block.

SBWG series double - wall corrugated pipe production line can continuously produce HDPE double - wall corrugated pipe and this line can achieve on-line belling.The machine has the function of automatic de-molding when power is off.The extruder adopt high-efficiency screw, the die head adopts double-layer spiral structure, mold die and core die being nitrided .The forming machine adopts vacuum forming type, equipped with automatic lubrication system.Forming mold is made of aluminiumalloy, adopt water cooling type.The pipe can be cut by on-line cutting machine automatically.

Our double wall corrugated pipe machine can use the aluminum module which with water cooling can vacuum cooling for high speed.We have professional designers and sophisticated processing machine to ensure the accuracy of the mold block.

|

Model

|

Pipe diameter

|

Extruder model

|

Motor power

|

Production speed

|

Mold pairs

|

(Optional)

Vacuum pump |

|

SJSBWG-50

|

32-50mm

|

SJ65/30&50/30

|

30kw&15kw

|

4-5m/min

|

72pairs

|

5.5kw

|

|

SJSBWG-110

|

50-110mm

|

SJ65/33&65/30

|

37kw&30kw

|

3-4m/min

|

72pairs

|

5.5kw

|

|

SJSBWG-160

|

75-160mm

|

75/33&65/30

|

45kw&37kw

|

2-3.5m/min

|

72pairs

|

5.5kw

|

|

SJSBWG-250

|

75-250mm

|

90/30&75/30

|

55kw&45kw

|

2-5m/min

|

72pairs

|

5.5kw*2

|

Advantage of our Plastic DWC double wall corrugated pipe machine

1. The main machine adopts special designed high efficiency screw which is specially used for HDPE,it has the features of stable performance and high

efficient

. The machine has two independence extruder ,which can realize both inside and outside layer with different material and colors.

2. Composite extrusion die head with specially helical structure to make the wall thickness uninfom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antumatically exit from the die head to avoid equipment failure in case of electricity cut off suddenly.It also equipped with new type high transmitting ratio reducer,easy to operate and maintain

4. The corrugated forming system is in combination with water cooling and air cooling to ensure high production speed

continuously.Advanced programmable lubricating system minimizes the molds wear so as to increase the life of service and ensure work smoothly with high precision to ensure the products quality stability.

5. Mold adopts specially aluminum alloy material and high precision die casting forming mold method,it has the advantages of high precision,high strength,good wear-ability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

2. Composite extrusion die head with specially helical structure to make the wall thickness uninfom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antumatically exit from the die head to avoid equipment failure in case of electricity cut off suddenly.It also equipped with new type high transmitting ratio reducer,easy to operate and maintain

4. The corrugated forming system is in combination with water cooling and air cooling to ensure high production speed

continuously.Advanced programmable lubricating system minimizes the molds wear so as to increase the life of service and ensure work smoothly with high precision to ensure the products quality stability.

5. Mold adopts specially aluminum alloy material and high precision die casting forming mold method,it has the advantages of high precision,high strength,good wear-ability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

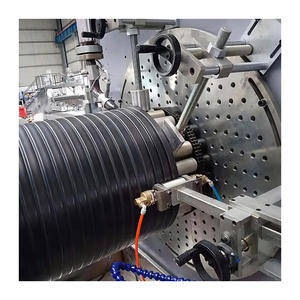

Detailed Images

1,Extruder for Double wall corrugated DWC pipe machine

Quantity: two sets,

Application: one is for outer wall,another is for inner wall.

Model: SJ75/33, SJ65/30

Extruder type: single screw extruder

Feeding: auto feeding with drying

Application: one is for outer wall,another is for inner wall.

Model: SJ75/33, SJ65/30

Extruder type: single screw extruder

Feeding: auto feeding with drying

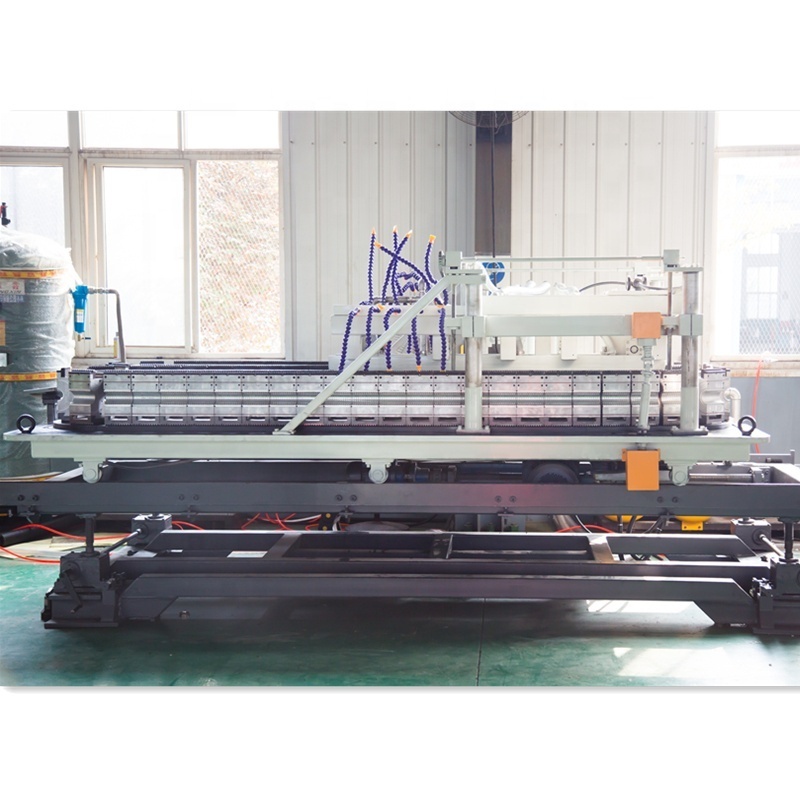

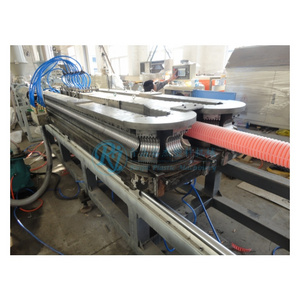

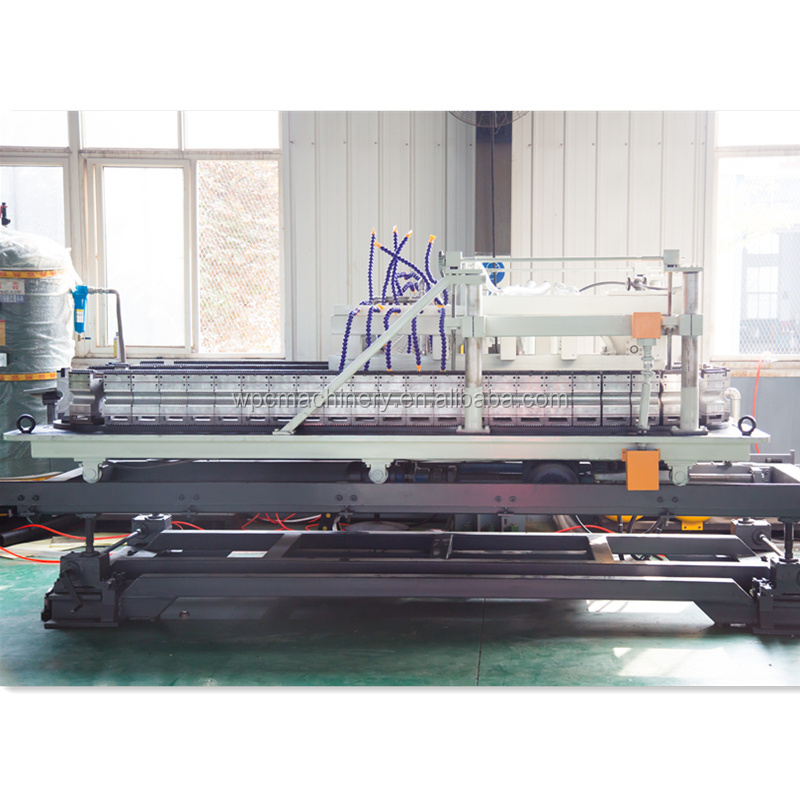

2,Forming machine for DWC double wall corrugated pipe machine:

Type A: water cooling type, one machine can work for all sizes for 40-250mm. speed can be 3-5 m/min.

Type B, vacuum cooling type, speed 2-4m/min, one machine for 40-110mm, another machine for 110-250mm

Material : High quality mold iron

Slide rail: Equipped with silde rail processed under special way, and process high strength and good abrasion resistance.

Cooling systerm: High efficency cooling systerm could be gurantee the quality of forming.

Lubrication systerm: Equipped with centralized lubrication device, automatic quantitative lubrication.

Type A: water cooling type, one machine can work for all sizes for 40-250mm. speed can be 3-5 m/min.

Type B, vacuum cooling type, speed 2-4m/min, one machine for 40-110mm, another machine for 110-250mm

Material : High quality mold iron

Slide rail: Equipped with silde rail processed under special way, and process high strength and good abrasion resistance.

Cooling systerm: High efficency cooling systerm could be gurantee the quality of forming.

Lubrication systerm: Equipped with centralized lubrication device, automatic quantitative lubrication.

3,Mold for DWC double wall corrugated pipe machine

Type A: 48 pairs, Aluminum material, inner hollow with water cooling channel, working for Type A forming machine.

Type B: solid Iron mold material, with air cooling and vacuum cooling, 72 pairs of mold blocks

Type A: 48 pairs, Aluminum material, inner hollow with water cooling channel, working for Type A forming machine.

Type B: solid Iron mold material, with air cooling and vacuum cooling, 72 pairs of mold blocks

4,Water cooling tank

Better cooling effect in order to improve the production speed .

Better cooling effect in order to improve the production speed .

5,Automatic chipless cutting machine

Automatic chipless cutting machine

6,Automatic winder device

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Double wall corrugated pipe application

HDPE double wall corrugated pipe

The double-wall corrugated pipe is formed by sintering and extruding the corrugated outer wall and a smooth inner wall

simultaneously extruded by HDPE. The section of the pipe wall is a double-layer structure, the inner wall is smooth and flat, and the outer wall is equirec tangularly arranged with a trapezoidal hollow structure. Pipe. It has excellent ring stiffness, good strength and toughness, light weight, strong impact resistance, not easy to break, etc., and it is easy to transport and install. The pipeline is mainly connected by rubber ring socket (also can be connected by heat shrinkable tape). Due to the special design of the wall structure of the double-wall corrugated pipe, under the condition of the same diameter and the same ring stiffness,the material (HDPE) is the least.

Product specifications are:

DN 40 mm, DN 50 mm, DN 63 mm, DN 75 mm, DN 90 mm, DN 110 mm, DN 125 mm, DN 150 mm, DN 220 mm, DN 225 mm, DN 250 mm, DN 300 mm, DN 400 mm, DN 500 mm, DN 600 mm,DN 700 mm, DN 800 mm, DN 1000 mm, DN 1200 mm, etc.

Advantages of double wall corrugated pipe

·Reasonable structure and beautiful appearance, temperature resistance -40ºC-60ºC, low resistance, large flow, strong flame retardancy ·Long service life, reliable sanitary performance, low overall cost ·Acid and alkali resistance, high strength, shock resistance strong performance. Energy saving and consumption reduction. Convenient installation and transportation

Our service

Our advantage

A.22 years manufacturer for plastic extruder machines,

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic

hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of

machine quality

Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for

the after-sell service.

Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and

keeping up with the times.

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic

hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of

machine quality

Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for

the after-sell service.

Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and

keeping up with the times.

Hot Searches