Tunnel Pasteurization tunnel machine is also called water spraying type can/bottle warming/cooling machine. Different from directly

heating type flash sterilizing machine, this series Tunnel Pasteurizer could sterilize liquid product together with its package

(glass or can or bags). It can kill all bacteria which possible exist in liquid product or package.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Dimension(L*W*H):

-

L6400mm*W3880mm*H2150mm

-

Weight:

-

3700 KG

-

name:

-

can depalletizer

-

Material:

-

SUS304/316

-

Capacity:

-

5000-40000bph

-

Bottle type:

-

Aluminum can, steel can

-

operation:

-

PLC And Touch screen

-

Marketing Type:

-

New Design

-

Advantage:

-

Easy Operation High Efficiency

-

Suitable for:

-

Beverage Packing Line

-

Usage:

-

Widely Used

-

Certification:

-

CE

Quick Details

-

Application:

-

Beverage, Machinery & Hardware

-

Packaging Material:

-

Plastic, Wood

-

Voltage:

-

380V/480V/220V, 50Hz/60Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Dimension(L*W*H):

-

L6400mm*W3880mm*H2150mm

-

Weight:

-

3700 KG

-

name:

-

can depalletizer

-

Material:

-

SUS304/316

-

Capacity:

-

5000-40000bph

-

Bottle type:

-

Aluminum can, steel can

-

operation:

-

PLC And Touch screen

-

Marketing Type:

-

New Design

-

Advantage:

-

Easy Operation High Efficiency

-

Suitable for:

-

Beverage Packing Line

-

Usage:

-

Widely Used

-

Certification:

-

CE

Product Overview

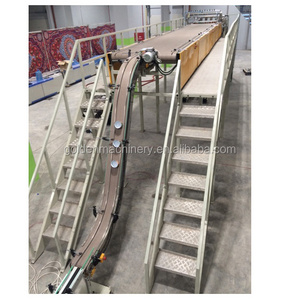

Automatic Can Depalletizer

High lever bulk can depalletizer are mechanical machine that unload (depalletize) packaged empty cans or glass bottles from the pallet. The depalletizer allows the transfer of products and materials from pallets without the use of human personnel, saving thus time, money and effort.

Equipment Details

Main structure

:

Full pallet conveyor, pallet lift device, whole layer cans pushing trolly, isolate remover, empty pallet stacker.

Full pallet conveyor, pallet lift device, whole layer cans pushing trolly, isolate remover, empty pallet stacker.

|

Model:

|

OK-400

|

|

Capacity/Speed:

|

0~24000 Bottles/Hour

|

|

Applicable:

|

Various Glass Bottle, Steel Cans,etc

|

|

Supply Power:

|

About 3.0KW

|

|

Voltage etc:

|

220V/380V,3Phase, 50Hz/60Hz

|

|

Air Consumption:

|

0.6m3/h

|

|

Air Pressure:

|

0.5-0.8Mpa

|

|

Working db:

|

≤75db

|

|

Machine Weight:

|

About 3700KG

|

|

Dimensions:

|

L6400mm*W3880mm*H2150mm(As Fact Design)

|

Advantages

High performing

High performing

Reliable

Flexible (in terms of container, format and pallet)

Quick and easy format changeover

Completely automated

Fully customizable

High operator safety standards

Appliance scope

For various metal cans, glass bottles, plastic bottles for layered depalletizing.

Depalletizer workflow and principles

Forklift put the whole stack cans/ bottles into unstacking station (hydraulic lift table)

Appliance scope

For various metal cans, glass bottles, plastic bottles for layered depalletizing.

Depalletizer workflow and principles

Forklift put the whole stack cans/ bottles into unstacking station (hydraulic lift table)

Chain lifter will transit the packed pallet to the upper most of the depalletizer.

Four sides clamps will hold the uppermost whole layer cans or bottles from four

sides, moving in parallel to the outlet multi lane conveyor.

Four sides camps open to release whole layer cans or bottles to the multi lane conveyor.

Then the four sides cylinder clamps will back to original position.

Pneumatic absorb hands will absorb the next layer top side isolate pad, move the pad to pad collector.

Chain lifter, hold the board rise to a certain height crib..

Do the same procedure until the last layer, Hydraulic lifts pallet fell to bottom, then transit to empty pallets stacker. Forklift remove the empty pallet. Repeat above actions.

Our Advantages

Touch screen(Siemens)

PLC(Mitsubishi /Siemens)

Solenoid Valve(FESTO)

Related Products

Can Sterilizer stunnel

Can PE Film wrapping machine

It can connect with the filling line directly by

conveyor system,All processfrom bottle feeding ,packing ,sealing ,cutting can works automatically

* Frequency control,Secondary bottle transport device.

* The whole set which are push bottle, heat sealing cutting adopt pneumatic structure.

* Inductive switch control film length.

conveyor system,All processfrom bottle feeding ,packing ,sealing ,cutting can works automatically

* Frequency control,Secondary bottle transport device.

* The whole set which are push bottle, heat sealing cutting adopt pneumatic structure.

* Inductive switch control film length.

Can Palletizer

1. Palletizer can put the cartons filled with products on the pallet in a fixed order and stack them automatically. The

multilayer of palletizing enables the fork moves them into storehouse. This equipment adopts PLC touch screen and intelligent

managing for realize man-machine interaction which is not only simple and easy to master, but also reducing the labor.

suitable for stacking carton,plastic case ,shrink wrapped product and five gallons bottling etc.It consists of Case

infeed,classification yard,pusher,pallet feeding etc.Optional interlayer keeps the stack more stable.It can be designed for

different palletizing requirements.

multilayer of palletizing enables the fork moves them into storehouse. This equipment adopts PLC touch screen and intelligent

managing for realize man-machine interaction which is not only simple and easy to master, but also reducing the labor.

suitable for stacking carton,plastic case ,shrink wrapped product and five gallons bottling etc.It consists of Case

infeed,classification yard,pusher,pallet feeding etc.Optional interlayer keeps the stack more stable.It can be designed for

different palletizing requirements.

Exhibition and Customer

Hot Searches