- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Nanyang

-

Machinery Capacity:

-

50kg/time

-

Machinery Function:

-

separating durian nuclear and Durian pulp, durian processing machine

-

Product name:

-

Durian pulp processing machine

-

Application:

-

separate durian meat and nuclear

-

Function:

-

durian processing

-

Usage:

-

durian farm and market processing

-

Material:

-

SUS 304 Stainless Steel

-

Advantage:

-

high speed and efficiency

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

durian meat

-

Process:

-

high speed centrifugal working

-

Capacity:

-

50L/time

Quick Details

-

Weight (KG):

-

100

-

Marketing Type:

-

hot sale in 2024

-

Place of Origin:

-

Foshan

-

Brand Name:

-

Nanyang

-

Machinery Capacity:

-

50kg/time

-

Machinery Function:

-

separating durian nuclear and Durian pulp, durian processing machine

-

Product name:

-

Durian pulp processing machine

-

Application:

-

separate durian meat and nuclear

-

Function:

-

durian processing

-

Usage:

-

durian farm and market processing

-

Material:

-

SUS 304 Stainless Steel

-

Advantage:

-

high speed and efficiency

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

durian meat

-

Process:

-

high speed centrifugal working

-

Capacity:

-

50L/time

Details Description

Factory price durian pulp processing machine durian meat and nuclear separating machine sus304 centrifugal machinery

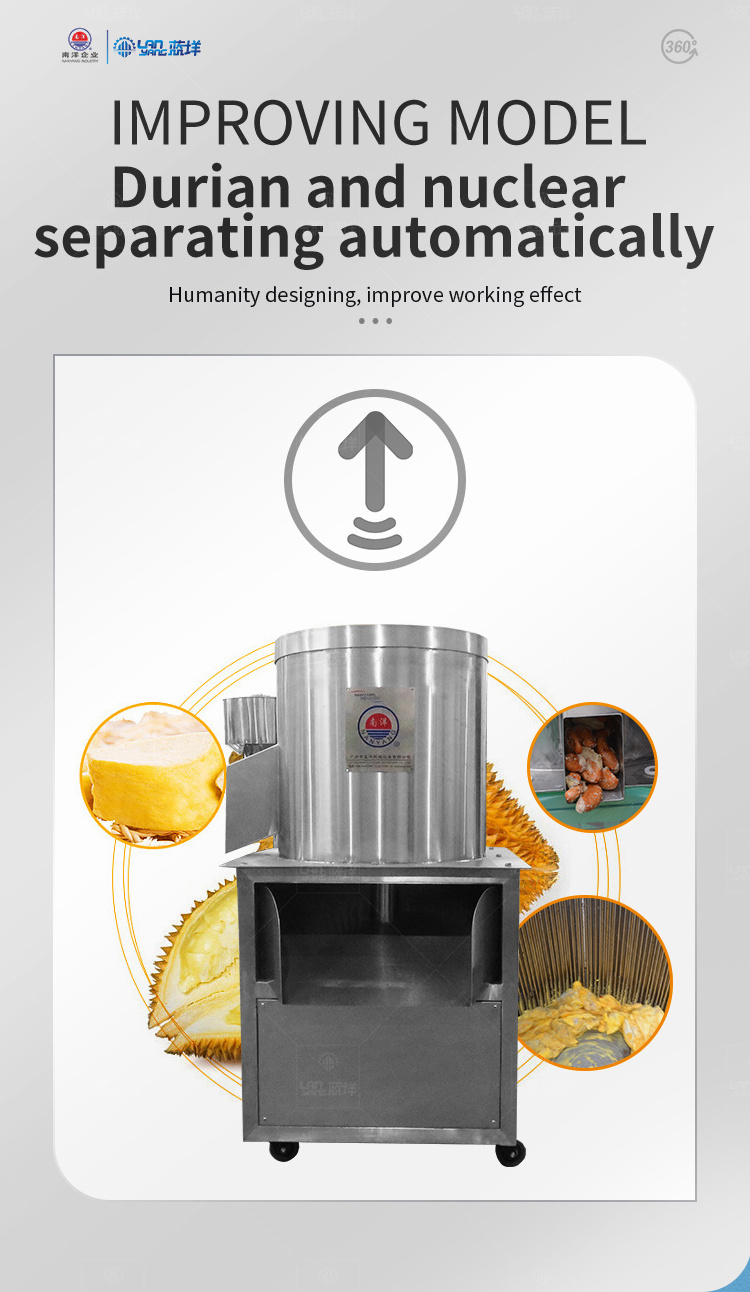

Usage

Suitable for removing the core of mature durian fruits, the durian flesh and core are separated by the centrifugal force of the motor, and then the durian flesh and core are automatically discharged from two separate ports. The equipment material is all made of food stainless steel, which meets the national food hygiene standards, is designed reasonably, has a compact structure, is easy to clean, has high throwing power, and separates the core and meat thoroughly. The cost is low and the effect is good

Suitable for removing the core of mature durian fruits, the durian flesh and core are separated by the centrifugal force of the motor, and then the durian flesh and core are automatically discharged from two separate ports. The equipment material is all made of food stainless steel, which meets the national food hygiene standards, is designed reasonably, has a compact structure, is easy to clean, has high throwing power, and separates the core and meat thoroughly. The cost is low and the effect is good

Feature

1. Full body food made of stainless steel 304 material, corrosion-resistant, and sturdy and durable .

1. Full body food made of stainless steel 304 material, corrosion-resistant, and sturdy and durable .

2.

The fruit pulp separation net is connected by small round steel, with no dead corners. The durian flesh is easy to separate and will not accumulate dirt and grime

.

3.

Install a fruit pit discharge port next to the barrel, which can be opened and automatically released after the durian flesh is separated. The operation is flexible and adjustable, with automatic pit discharge and continuous operation

.

4.

The motor is sealed and separated from the barrel, and the machine can be rinsed with water, reducing the difficulty of cleaning for customers.

5.

The discharge port at the bottom of the bucket adopts a large angle inclined plate, and the smooth surface makes it easier for the material to flow out.

6.

Install casters and foot plates at the bottom, allowing the device to move flexibly and be fixed at any time, eliminating environmental impact on users.

7. The durian meat throwing machine uses the principle of a centrifuge to separate the fruit pulp, and is equipped with a frequency conversion speed control function. The speed is completely controlled independently, so there is no need to worry about the speed being too fast or too slow. Variable frequency speed regulation, fully meeting the requirements of durian flesh dehulling speed. After the separation of the core, the flesh becomes delicate and muddy, hygienic and clean, with no residue of fruit core.

8.

Equipped with a stainless steel electrical control box, the speed and speed of the equipment can be automatically adjusted during operation, and real-time monitoring can be carried out to achieve the best state of materials

.

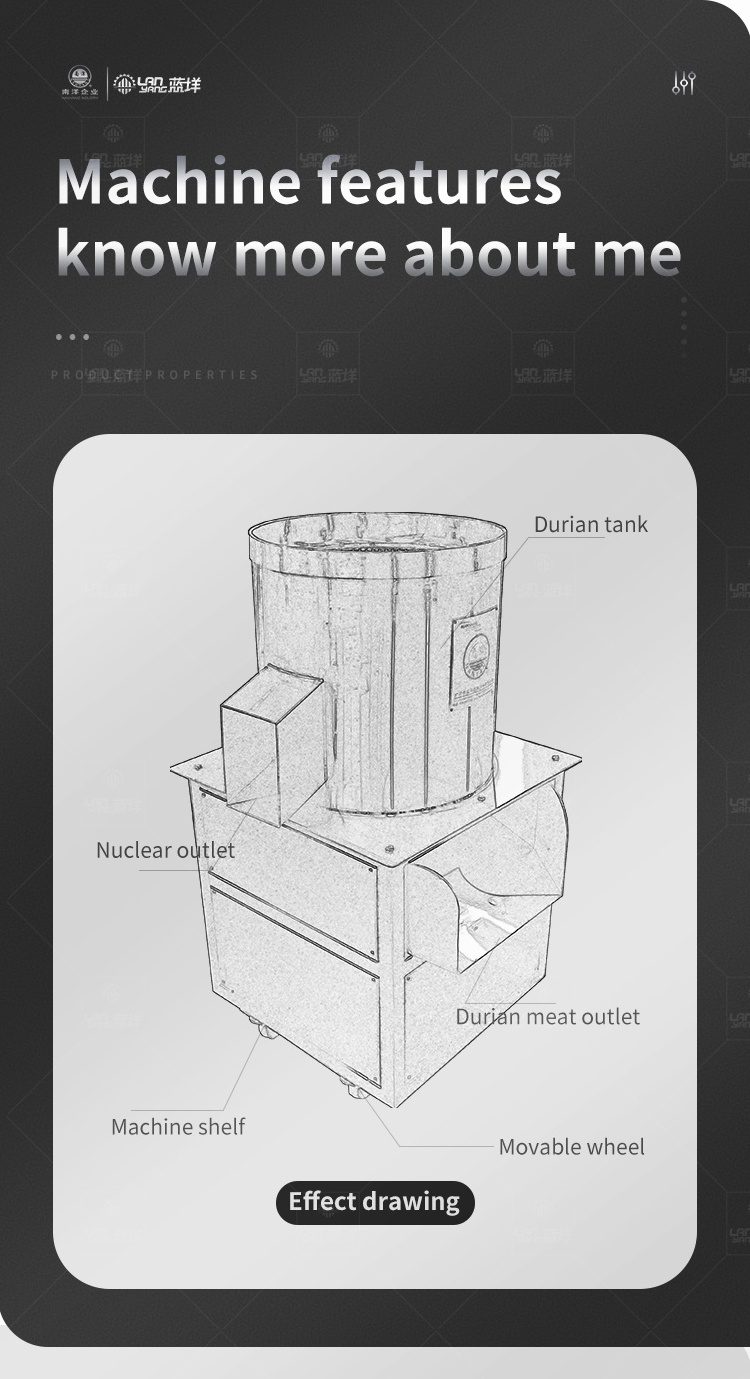

Material outlet, big mouth, easy to discharge, made of food sus304

The electric controller box can use all functions in one key and button

The movable wheel can move tank at anywhere and anytime usage

The nuclear outlet controlled hand by manual is easy to operate using

The separating tank all parts made sus304 meet food grade demands

The separating gas are smaller by most of nuclear diameter perform

|

Total Volume

|

Effect Volume

|

Working Time

|

Power

|

Speed

|

Speed Adjust

|

Made Of

|

|

67L

|

50L

|

5-10min

|

2.2kw

|

0-466r/min

|

Converter

|

SUS304

|

Suitable Material

Details Images

Hot Searches