- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V 50Hz

-

Place of Origin:

-

China

-

Brand Name:

-

HY-Filling

-

Dimension(L*W*H):

-

2440*2100*2200mm

-

Weight:

-

2.2 KG

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC

-

Air Pressure:

-

0.3-0.6Mpa

-

Filling head:

-

12-60

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000bph

-

Brand:

-

Mesure

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Voltage:

-

220V/380V 50Hz

-

Place of Origin:

-

China

-

Brand Name:

-

HY-Filling

-

Dimension(L*W*H):

-

2440*2100*2200mm

-

Weight:

-

2.2 KG

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC

-

Air Pressure:

-

0.3-0.6Mpa

-

Filling head:

-

12-60

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000bph

-

Brand:

-

Mesure

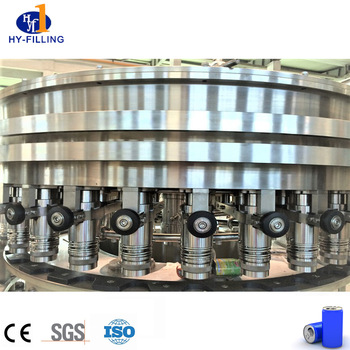

Rinsing-Filling-Capping 3-in-1 Monoblock

It is used to clean empty can in canning production line. Empty cans will be sent to turning device first, which will be turned around then transferred into rinsing machine. Empty can will be running from top to bottom along the turning device. When empty cans enter into rinser, they will be cleaned by 80℃ hot water (provided by customer) to reach aseptic state of can. There is certain inclination angle in both sides of rinser, whose size could be adjusted properly when needed. Empty cans will be rolling in parallel way from top to end; the waste water will be discharged from outfall

It is suitable for filling and capping carbonated beverage such as beer, CSD, etc. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

|

Main

composition

|

|

|

|

PLC

|

Mitsubishi, Siemens

|

|

|

Touch screen

|

Mitsubishi, Siemens, PROFACE

|

|

|

Frequency converter

|

Mitsubishi, Siemens, Danfoss

|

|

|

Air switch

|

Schneider

|

|

|

Contactor

|

Siemens

|

|

|

Breaker

|

Siemens

|

|

|

Photoelectric switch

|

Omron, Keyence, P+F

|

|

|

Approach switch

|

Truck

|

|

|

Main bearing

|

NTN

|

|

|

Lubrication bearing

|

IGUS

|

|

|

Sealing

|

Sealtech

|

|

|

Pneumatic components

|

Camozzi

|

|

Product Paramenters

|

Model

|

YGF20-4

|

YGF30-6

|

YGF40-6

|

YGF40-8

|

|||

|

Capacity

|

0~9000BPH

|

9000~18000BPH

|

18000~24000BPH

|

24000~27000BPH

|

|||

|

Suitable bottle

|

PET or Aluminum can

|

|

|

|

|||

|

Bottle diameter

|

53-66mm

|

|

|

|

|||

|

Bottle height

|

70-175mm

|

|

|

|

|||

|

Machine weight

|

500kg

|

|

|

|

|||