- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

shandong

-

Brand Name:

-

DEYI

-

Model Number:

-

DY-800

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2300X2600X2400

-

Weight:

-

8500 KG

-

Application:

-

Clothing Packaging

-

Function:

-

Producing Plastic Shopping Bag

-

Suitable material:

-

HDPE LDPE LLDPE

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Speed:

-

80-120pcs/min

-

Max width of bag:

-

8000mm

-

Maximum length of bag:

-

400mm

-

Maximum diameter of unwinding:

-

paper or film 800mm

-

Feature:

-

Great After-sale Service

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

T-shirt Bag

-

Material:

-

Plastic

-

Place of Origin:

-

shandong

-

Brand Name:

-

DEYI

-

Model Number:

-

DY-800

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2300X2600X2400

-

Weight:

-

8500 KG

-

Application:

-

Clothing Packaging

-

Function:

-

Producing Plastic Shopping Bag

-

Suitable material:

-

HDPE LDPE LLDPE

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Speed:

-

80-120pcs/min

-

Max width of bag:

-

8000mm

-

Maximum length of bag:

-

400mm

-

Maximum diameter of unwinding:

-

paper or film 800mm

-

Feature:

-

Great After-sale Service

Product Description

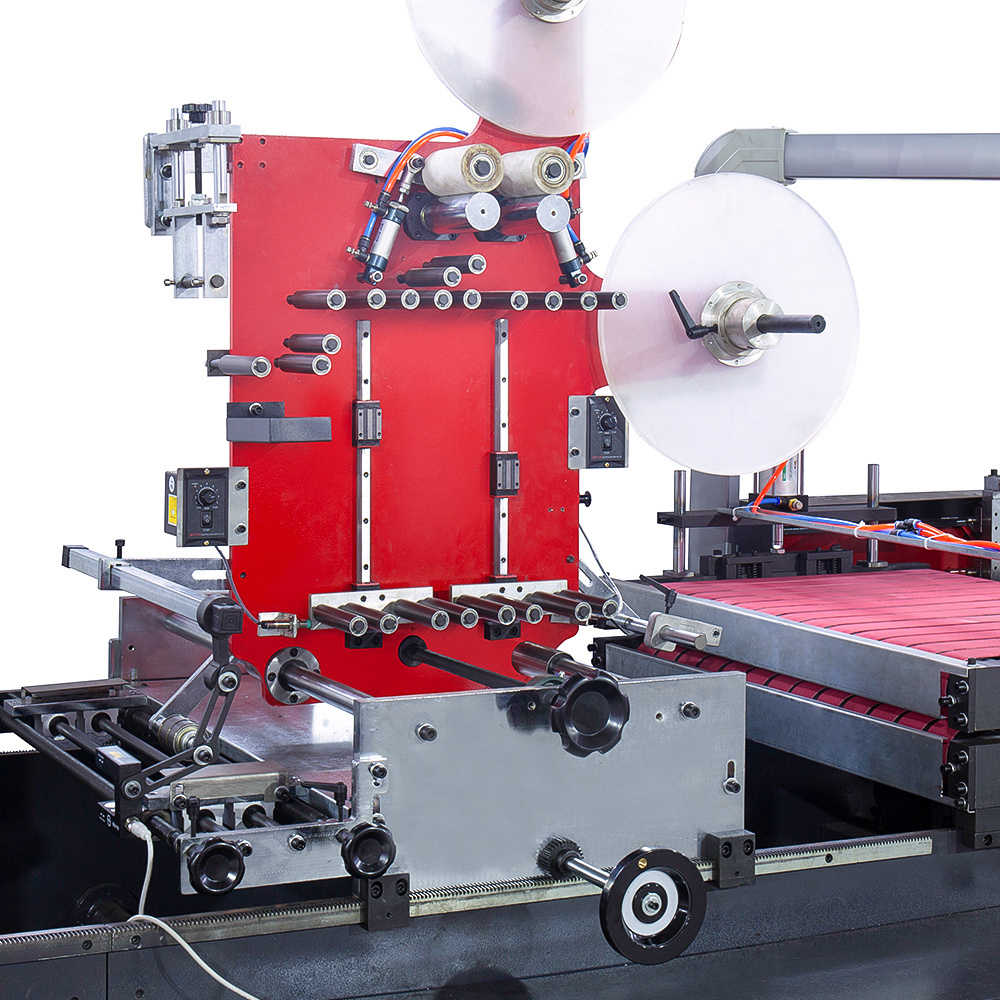

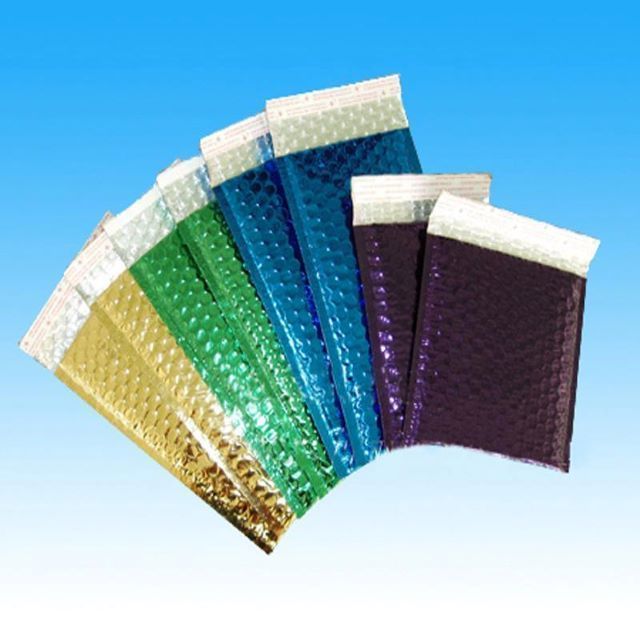

2024 Kraft paper laminated air bubble bag mailer envelope making machine Air bubble film envelop making machine automatic shockproof foam air bubble bag making machine

Longkou UNITY Mechanical Equipment Co, Ltd, established in 1980. is a SINO-ITALY joint venture with advanced leading technolog, We specialize in manufacturing the following products: Plastic Foaming Machine, Packing Machinery, Pulp Moulding Machinery more than 30 years expenences. Our enterprise management concept is based on innovation, excellent quality and skilled workmanship. We are enjoying a good reputation through over 100 countries and areas and have got customers' trust deeply.Moreover, our sales volume of foaming mahcine is No.1 compared with other Chinese suppliers. We sincerely hope to cooperate with friends from and abroad and help you succeed with our profession.

Wealth effect

With the continuous development of the e-commerce industry and the increasing demand for logistics distribution, the market demand is also continuing to grow. Its low cost and convenient use make it have a high profit space, especially in the case of fierce

competition in the express packaging market, as a cost-effective packaging choice, it can win more market share and bring considerable economic benefits.

competition in the express packaging market, as a cost-effective packaging choice, it can win more market share and bring considerable economic benefits.

Environmental protection and energy saving

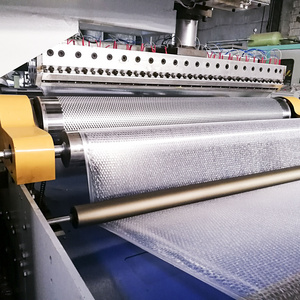

Bubble film express bag is of great significance in recycling. Its main components are plastic materials such as polyethylene, which are processed and reused in the production of new packaging materials or other plastic products. This recycling process helps to reduce resource consumption and waste generation, reduce environmental load and promote sustainable development.

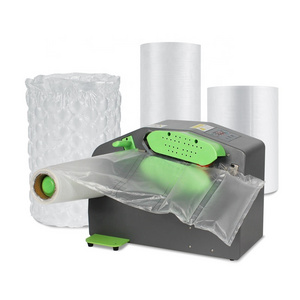

Introduction of bubble film bag making machine

The bubble film bag making machine, with its efficient production and high-quality packaging capabilities, has become a lucrative tool in today's packaging industry. Its versatile production capacity meets the market's demand for bubble film bags of various sizes, thicknesses, and types. Additionally, by utilizing energy-saving and environmentally friendly technologies and materials, it aligns with the modern societal emphasis on environmental protection, making it even more favored by users. With the growing emphasis on environmental sustainability and product quality in the market, the bubble film bag making machine will continue to play a significant role and hold promising prospects in future market development.

Specification

|

1.Suitable bags

|

Poly bubble mailer and Kraft bubble mailer.(The machine can make laminating and folding two side seal bubble envelope.)

|

|

2.Mechanical executing speed

|

90 pcs/min(The actual speed of making bags may differ according to the size of bags, thickness of materials and time of fusing.)

|

|

3. Max width of bag

|

One line: 800mm (including the envelope flap)

Double line: 400mm (including the envelope flap) |

|

4.Maximum length of bag

|

400mm

|

|

5.Maximum width of unwinding

|

paper or film(1400mm bubble 1350mm)

|

|

6.Maximum diameter of unwinding

|

paper or film Φ800mm, bubble Φ1300mm

|

|

7.Weight of machine

|

8500kg

|

|

8.Overall dimension

|

23000X2600X2400mm(L×W×H)

|

|

9.Power required

|

80KW

|

|

10.Voltage

|

three-phase five-wire, AC 380V 50Hz

(three firing line, one null line, one ground lead) |

Products Description

Cutter

1.The machine independently uses AC servo motor to control cutting.

2.The cooling cutter is controlled by the stepper motor for

forth and rear shift cutting with electric eye to track printing color mark.

3.The movement of cutter is accurately controlled by type AC servo motor.

4. This part has Plexiglas protector.

forth and rear shift cutting with electric eye to track printing color mark.

3.The movement of cutter is accurately controlled by type AC servo motor.

4. This part has Plexiglas protector.

Haul Off Unit

1. It has good cushioning, reduces the wear of mechanical parts, and extends the service life of the equipment

2. High transmission efficiency, can reach more than 90%

3. Reduce machine noise and improve the working environment

4. Installation and maintenance is relatively simple and does not require professional technicians

Hot Searches