- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JXSC

-

Product name:

-

VSI Vertical Shaft Impact Crusher Rotor

-

Color:

-

Customer's Requirement

-

Certification:

-

CE ISO

-

MOQ:

-

1 Set

-

Quality:

-

High Level

-

Advantage:

-

High Performance

-

Standard:

-

International

-

Packing:

-

Wooden Box

-

Feature:

-

High Strengh

-

Delivery time:

-

7-15 Days

Quick Details

-

Weight (KG):

-

600

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Product name:

-

VSI Vertical Shaft Impact Crusher Rotor

-

Color:

-

Customer's Requirement

-

Certification:

-

CE ISO

-

MOQ:

-

1 Set

-

Quality:

-

High Level

-

Advantage:

-

High Performance

-

Standard:

-

International

-

Packing:

-

Wooden Box

-

Feature:

-

High Strengh

-

Delivery time:

-

7-15 Days

Products Description

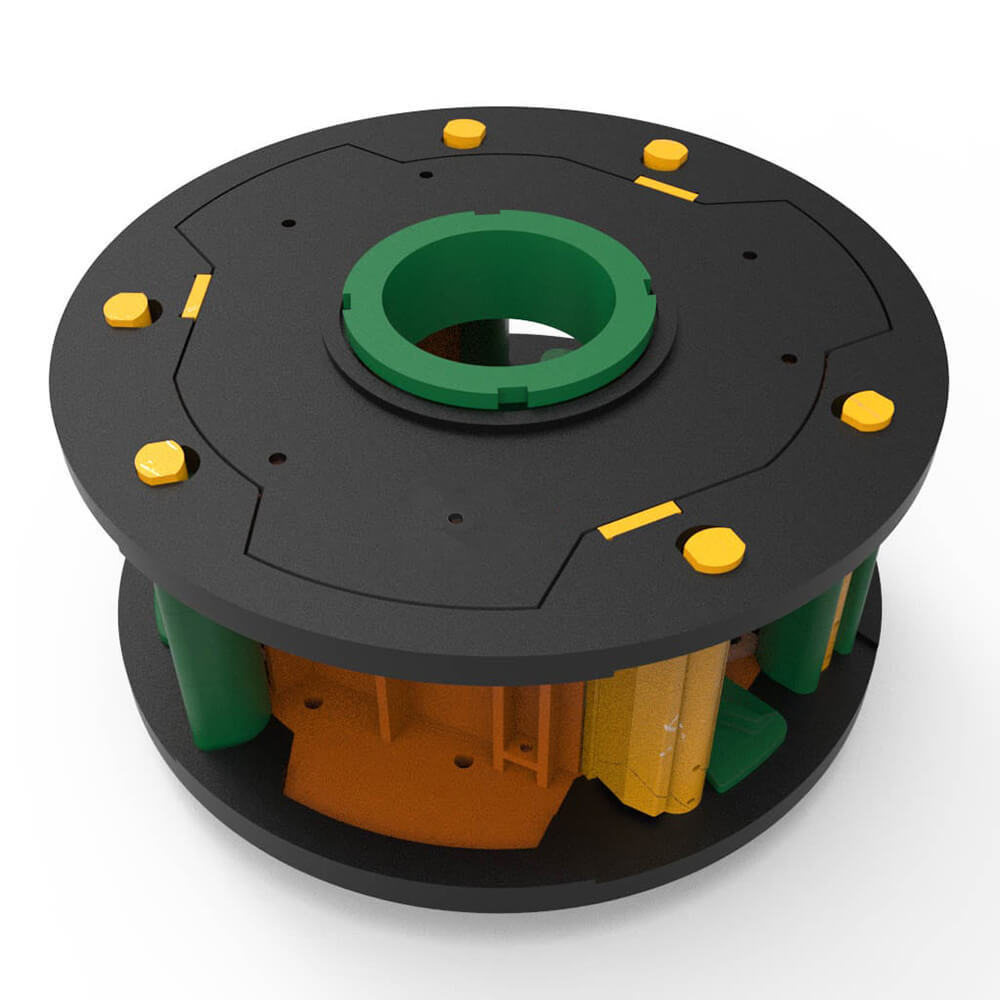

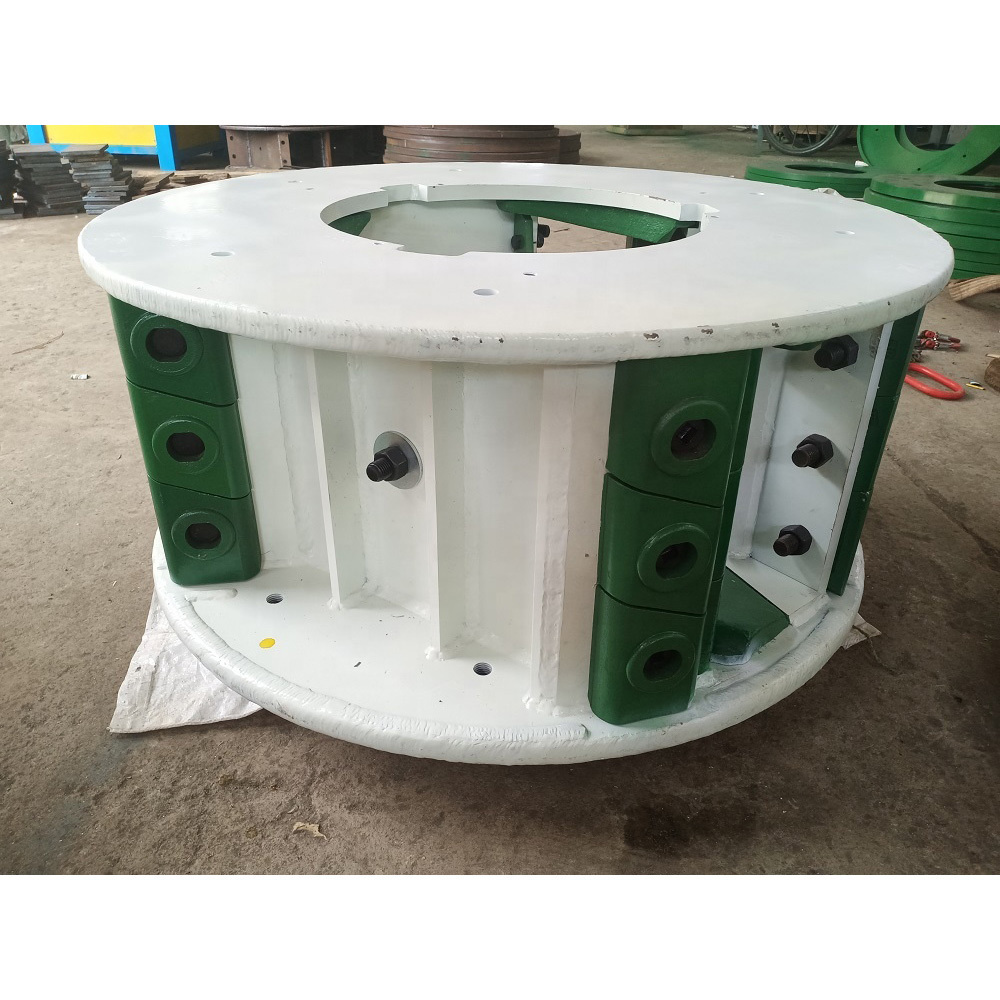

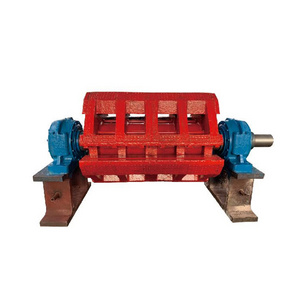

VSI CRUSHER SPARE PARTS

The rotor, being the heart of the Vertical Shaft Impactor (VSI), is designed for high capacity with a low power consumption. The wear parts for a VSI rotor are contained both within and on the outer surfaces of the rotor. Different parts have material technology to resist either impact or abrasive wear.

Selection of the correct wear parts for the application required is fundamental to ensure the desired performance.

JXSC holds a huge stock inventory of premium quality compatible spare parts and wear parts to suit a popular range of VSI, including:

Metso® Barmac® B Series Sandvik® CV Series Trio® TV Series Terex® Canica

Why choose US

WALKER guarantee a 100% matching to the OEM parts WALKER VSI spare parts are trusted by VSI operators all over the world, due to their 100% adaptability and the same quality as the OEM parts

Affordable prices with on-time delivery, allows you to easily arrange the order cycle to ensure continuous and stable project

operation. Affordable prices with on-time delivery, allow you to easily arrange the ordering cycle, a reliable supply chain to

keep your project stable.

operation. Affordable prices with on-time delivery, allow you to easily arrange the ordering cycle, a reliable supply chain to

keep your project stable.

JXSC spare parts bring you benefits by premium wear life and service life, our wearing parts minimize the downtime of your machines, thus to reduce the cost per ton. JXSC spare parts bring you benefits by premium wear life and service life, our wearing parts minimize the downtime of your machines, thus to reduce the cost per ton.

Metso Barmac Series Crusher Parts

ELIMINATOR SERIES ROTOR Eliminator series rotor is the traditional and well-established style of rotor for Barmac capable of performing in all applications. WALKER holds the most spare and wear parts of this kind of rotor in-stock to support your machine. The features of this rotor are:

● Solid, well proven design

● Capable of taking all types of feed types and conditions

● Segmented tips to maximize lifetime

● Fits all models of Barmac crushers

RC SERIES ROTOR (THE NEW ORANGE SERIES) Now WALKER is able to supply the lastet technologies of Metso Barmac VSI rotors, the RC series rotor. It keeps your VSI crusher up and running longer than ever before. The features of this rotor are:

● Increased wear part lifetime

● Improved serviceability, less downtime

● Faster change out of parts

● Segmented tips to maximize lifetime

● Fits also to older models

● Deep rotor technology maximizes capacity

● Less parts needed to dress a rotor

● More parts can be changed through the service door

Barmac B-Series VSI crushers have many different wear parts inside the Rotor. Including:

* Rotor Tips, Back-up Tips, Tip / Cavity Wear Plates to protect all areas of the exit ports

* Upper and Lower internal wear plates to protect the inner body of the rotor

* Internal distributor plate to receive initial entry impact and distribute the material to each port

* Feed Tube and Feed Eye Ring to guide the material centrally into the rotor

* Internal Trail plates to maintain rotor stone beds formed during operation

* Rotor Tips, Back-up Tips, Tip / Cavity Wear Plates to protect all areas of the exit ports

* Upper and Lower internal wear plates to protect the inner body of the rotor

* Internal distributor plate to receive initial entry impact and distribute the material to each port

* Feed Tube and Feed Eye Ring to guide the material centrally into the rotor

* Internal Trail plates to maintain rotor stone beds formed during operation

The wear parts that are worn the most inside the rotor are the Distributor plate, Rotor Tips, Lower wear plates and Feed tube.This happens because these parts have direct contact with the feed material at all times as it passes through the rotor.

Specification

JXSC® "Genuine Alternative" VSI parts are designed to extend wear life, provide a perfect interchangeable fitting for your

machine, and increase production rates while decreasing costs-per-ton.

machine, and increase production rates while decreasing costs-per-ton.

|

Barmac B Series

|

Sandvik CV Series

|

Trio TV Series

|

Terex Canica

|

|

B6150SE

|

CV215

|

TV85

|

2000 VSI

|

|

B7150SE

|

CV216

|

TV95

|

|

|

B9100SE

|

CV217

|

|

|

|

|

CV218

|

|

|

|

|

CV228

|

|

|

|

|

CV229

|

|

|

*NOTE: All manufacturer names, part numbers, model numbers and descriptions are used for reference and identification purposes only, they are owned by the respective machine manufacturer. All parts supplied are manufactured and warranted by JXSC and are not manufactured by or purchased from the Original Equipment Manufacturer. JXSC has no association with the OEM and do not intend to give this impression.

Packing and Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Hot Searches