The machine is mainly used for automatic filling of mini bottles (1-100ml) of electronic cigarette oil, eye drops, seal oil and other liquids. In addition, it can also be equipped with a press stopper (optional), cap uploader, screw cap machine (optional), etc.

In addition, we have machines for filling materials such as powder granules. It’s the ideal equipment in such industries likes pharmacy, food, chemical industry etc.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.2%

-

Voltage:

-

380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RYBO

-

Dimension(L*W*H):

-

1600*1000*1400mm

-

Weight:

-

500 KG

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Machinery Capacity:

-

2000BPH, 3000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Water, Oil

-

Filling Accuracy:

-

0.2%

-

Voltage:

-

380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RYBO

-

Dimension(L*W*H):

-

1600*1000*1400mm

-

Weight:

-

500 KG

-

Marketing Type:

-

Hot Product 2019

Product Description

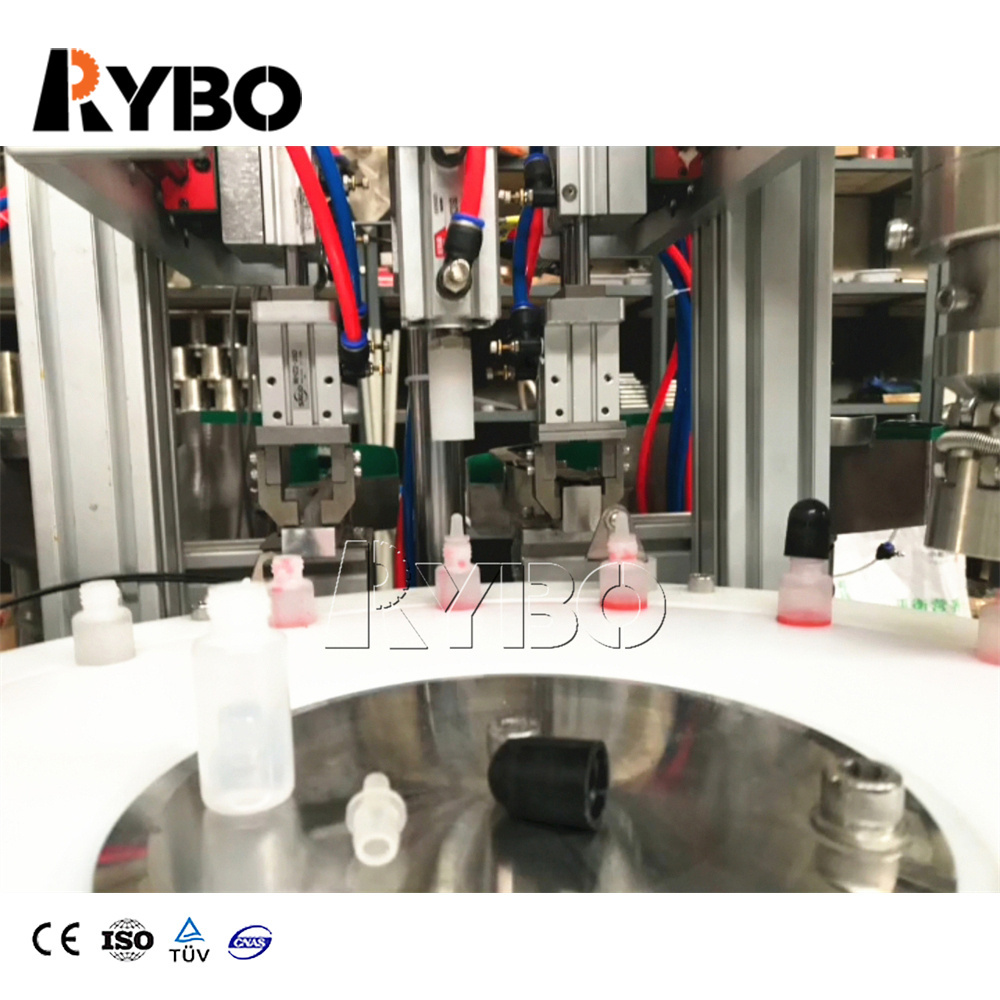

Automatic Mini Bottle Liquid Filling Machine (1-100ml)

Application

Specification

Features:

1. It adopts peristaltic pump filling, which is more accurate and faster.

2. No bottle no filling, and without dropping when filling.

3. Magnetic moment capping head to screw the caps. Capping tightly and not hurt caps.

2. No bottle no filling, and without dropping when filling.

3. Magnetic moment capping head to screw the caps. Capping tightly and not hurt caps.

|

Items

|

Parameters

|

|

Suitable Bottle Size

|

1-100ml (can be customized)

|

|

Production Capacity

|

30-50 bottles/min (can be customized)

|

|

Power

|

380V 50Hz

|

|

Power Consumption

|

≤1.2KW

|

|

Air Pressure

|

0.6-0.8Mpa

|

|

Stand-Lone Noise

|

≤50dB

|

Touch Screen

High Quality Air Pressure Meter

Peristaltic Pump Filling Part

High Quality Capping Part

If you need bigger machine, please feel free to contact with us.

Production Capacity can be up to 30000bph.

The Complete Line

We Can Supply Turnkey Project From A to Z

Normally Speaking, The whole complete vial filling production line including:

1. Bottle Feeder

2. Filling Machine

3. Capping Machine

4. Coding Machine

5. Labeling Machine

6. Film Packing Machine

Some machines can also be increased to the production line according to customer requirements, such as

Foil Sealer, Carton Packer, Palletizers,

etc.

Hot Searches