- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

220v,380v, or base on customer's requirements

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NewWay

-

Dimension(L*W*H):

-

3050x1750x1900mm

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Video technical support

-

Product name:

-

automatic tin can CIP cleaning liquid filling and sealing machine

-

Material:

-

304/316 Stainless Steel

-

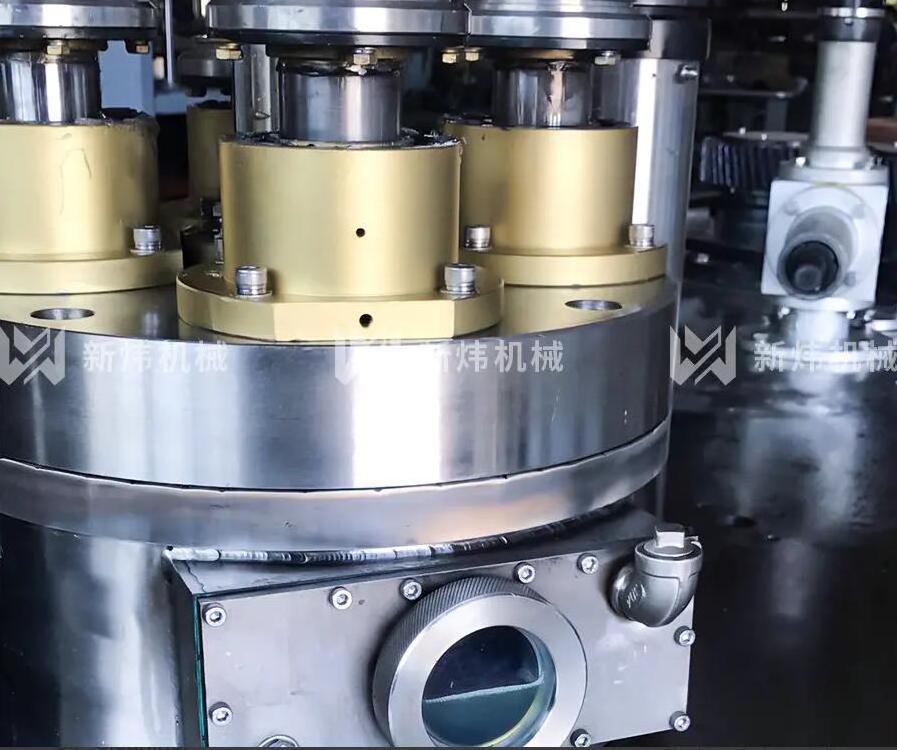

Filling head:

-

18 Heads

-

Sealing head:

-

4 Heads

-

Production capacity:

-

30-250cans/min

-

Speed:

-

can be adjusted

Quick Details

-

Machinery Capacity:

-

20000BPH

-

Packaging Material:

-

Plastic, Metal, Glass, tin/aluminum

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

220v,380v, or base on customer's requirements

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NewWay

-

Dimension(L*W*H):

-

3050x1750x1900mm

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Video technical support

-

Product name:

-

automatic tin can CIP cleaning liquid filling and sealing machine

-

Material:

-

304/316 Stainless Steel

-

Filling head:

-

18 Heads

-

Sealing head:

-

4 Heads

-

Production capacity:

-

30-250cans/min

-

Speed:

-

can be adjusted

Product Description

The material cylinder of this machine has an automatic CIP cleaning pipeline system, and it adopts closed type.

The external CIP cleaning fluid enters the material cylinder through the pipeline to clean the material cylinder thoroughly. The special cylinder supports the filling valve to clean the valve with CIP liquid.

The CIP pipeline has the function of reflux circulation. Automatic CIP pipeline system mainly includes CIP intake module, valve opening cylinder module, CIP liquid reflux pipeline module, electrical control, fake cup set.

The external CIP cleaning fluid enters the material cylinder through the pipeline to clean the material cylinder thoroughly. The special cylinder supports the filling valve to clean the valve with CIP liquid.

The CIP pipeline has the function of reflux circulation. Automatic CIP pipeline system mainly includes CIP intake module, valve opening cylinder module, CIP liquid reflux pipeline module, electrical control, fake cup set.

Cleaning process

1、Manually install all the fake cups at the bottom of each filling valve to ensure the sealing of the filling valve.

2、Start the cylinder button for opening the valve and force all filling valves to be opened.

3、Open the pneumatic butterfly button of the CIP pipeline on the top of the filling barrel, let the CIP liquid enter the filling barrel by the pressure difference. Clean the inside of the filling barrel, switch the pipeline system, let the CIP liquid enter the filling valve for automatic cleaning and recovery.

4、The CIP liquid are returned the main pipeline at the bottom of the equipment through the pipeline system connected to the bottom of each filling valve, and the CIP liquid are recovered through the main pipeline.

2、Start the cylinder button for opening the valve and force all filling valves to be opened.

3、Open the pneumatic butterfly button of the CIP pipeline on the top of the filling barrel, let the CIP liquid enter the filling barrel by the pressure difference. Clean the inside of the filling barrel, switch the pipeline system, let the CIP liquid enter the filling valve for automatic cleaning and recovery.

4、The CIP liquid are returned the main pipeline at the bottom of the equipment through the pipeline system connected to the bottom of each filling valve, and the CIP liquid are recovered through the main pipeline.

Size Information

|

Model

|

XW18-4A

|

|

The number of sealing head

|

4

|

|

The number of filling head

|

18

|

|

Production capacity

|

30-250cans/min

|

|

Can diameter

|

Φ52.5-99mm

|

|

Can height

|

39-160mm

|

|

Power

|

7.5kw

|

|

Weight

|

4000kg

|

|

Dimension

|

3050*1750*1900mm

|

Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Engineers available to service machinery overseas.

* Field installation, commissioning and training.

* Field maintenance and repair service.

* Field installation, commissioning and training.

* Field maintenance and repair service.

Company Introduction

Zhejiang NewWay Food Machinery Co., Ltd. is located in Zhoushan, the Oriental Pearl City Thousand Island City. It is 16 kilometers away from Mount Putuo airport. There are multiple flights to and fro Shanghai international airport everyday, 98 kilometers away from Ningbo Lishe airport, the traffic is very convenient.

The company is mainly engaged in the design and manufacture of beverages, canning machine and sealing machine packed with tinplate, aluminum, plastic and paper materials, as well as related products. Undertake the whole production line of easy-to-open beverage (including steam, non steam), sauce filling and sealing production line, Babao porridge canning, food, fruit and vegetable canning production line, etc.

The company fully uses CAD and CAM to design products. It is in a leading position in the field of filling and sealing equipment for canned food and beverage in China. The company specializes in the production of high-speed canning filling and sealing units and production lines, which make due contributions to the localization of similar imported equipment, reduce investment costs in the food and beverage industry, improve labor productivity of enterprises, and promote the rapid development and growth of the industry.

The company relies on strong technical force and effective technical guarantee, flexible business philosophy and quality service, advanced manufacturing technology, excellence in product quality and good reputation, to serve the vast number of new and old customers and welcome friends from all walks of life to visit and patronize.

The company is mainly engaged in the design and manufacture of beverages, canning machine and sealing machine packed with tinplate, aluminum, plastic and paper materials, as well as related products. Undertake the whole production line of easy-to-open beverage (including steam, non steam), sauce filling and sealing production line, Babao porridge canning, food, fruit and vegetable canning production line, etc.

The company fully uses CAD and CAM to design products. It is in a leading position in the field of filling and sealing equipment for canned food and beverage in China. The company specializes in the production of high-speed canning filling and sealing units and production lines, which make due contributions to the localization of similar imported equipment, reduce investment costs in the food and beverage industry, improve labor productivity of enterprises, and promote the rapid development and growth of the industry.

The company relies on strong technical force and effective technical guarantee, flexible business philosophy and quality service, advanced manufacturing technology, excellence in product quality and good reputation, to serve the vast number of new and old customers and welcome friends from all walks of life to visit and patronize.

Hot Searches