- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SUMU

-

Voltage:

-

220V /380V /customized

-

Dimension(L*W*H):

-

8800*2900*2900mm

-

Weight (KG):

-

12000 kg

-

Molding cycle:

-

40s

-

Moisture content:

-

12%-16%

-

Allowable Pressure:

-

4Mpa

-

Vacuum Degree:

-

<=0.092Mpa

-

Spindle Speed:

-

29.7-21.5r/min

-

Motor Power:

-

90kw+250kw

-

Color:

-

customized

-

After-sales Service Provided:

-

Engineer Overseas Service

-

Package:

-

wooden box

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

8000-20000pc/hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SUMU

-

Voltage:

-

220V /380V /customized

-

Dimension(L*W*H):

-

8800*2900*2900mm

-

Weight (KG):

-

12000 kg

-

Molding cycle:

-

40s

-

Moisture content:

-

12%-16%

-

Allowable Pressure:

-

4Mpa

-

Vacuum Degree:

-

<=0.092Mpa

-

Spindle Speed:

-

29.7-21.5r/min

-

Motor Power:

-

90kw+250kw

-

Color:

-

customized

-

After-sales Service Provided:

-

Engineer Overseas Service

-

Package:

-

wooden box

Product Description

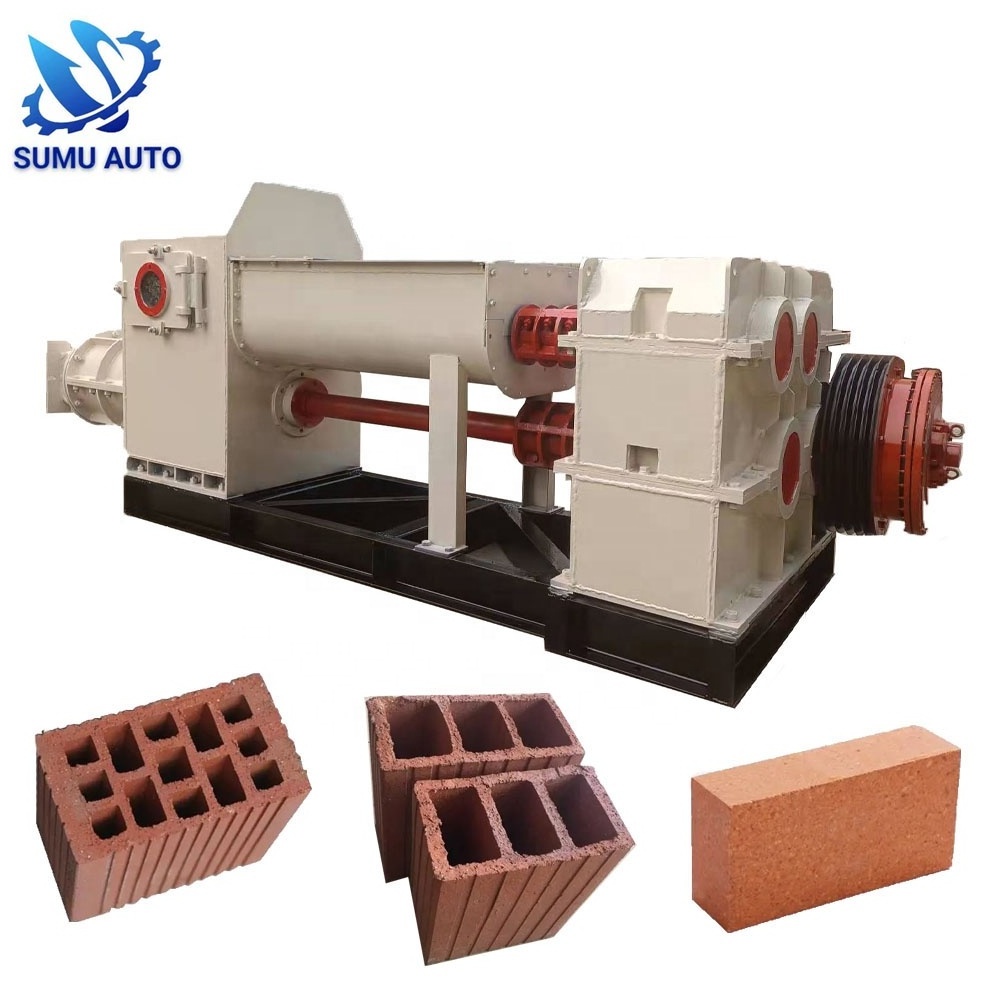

Our company produces various clay brick making machines, automatic vacuum brick making machines, semi-automatic vacuum brick making machines,manual red clay brick making machines.

1. Send a set of solid brick mold for free.

2. This automatic vacuum clay brick making machine can produce different types of bricks, hollow bricks and solid bricks, and supports customization. Welcome to consult!

3.We also provide the design and construction of the whole brick machine production line. Provide tunnel kiln construction and turnkey works.

1. Send a set of solid brick mold for free.

2. This automatic vacuum clay brick making machine can produce different types of bricks, hollow bricks and solid bricks, and supports customization. Welcome to consult!

3.We also provide the design and construction of the whole brick machine production line. Provide tunnel kiln construction and turnkey works.

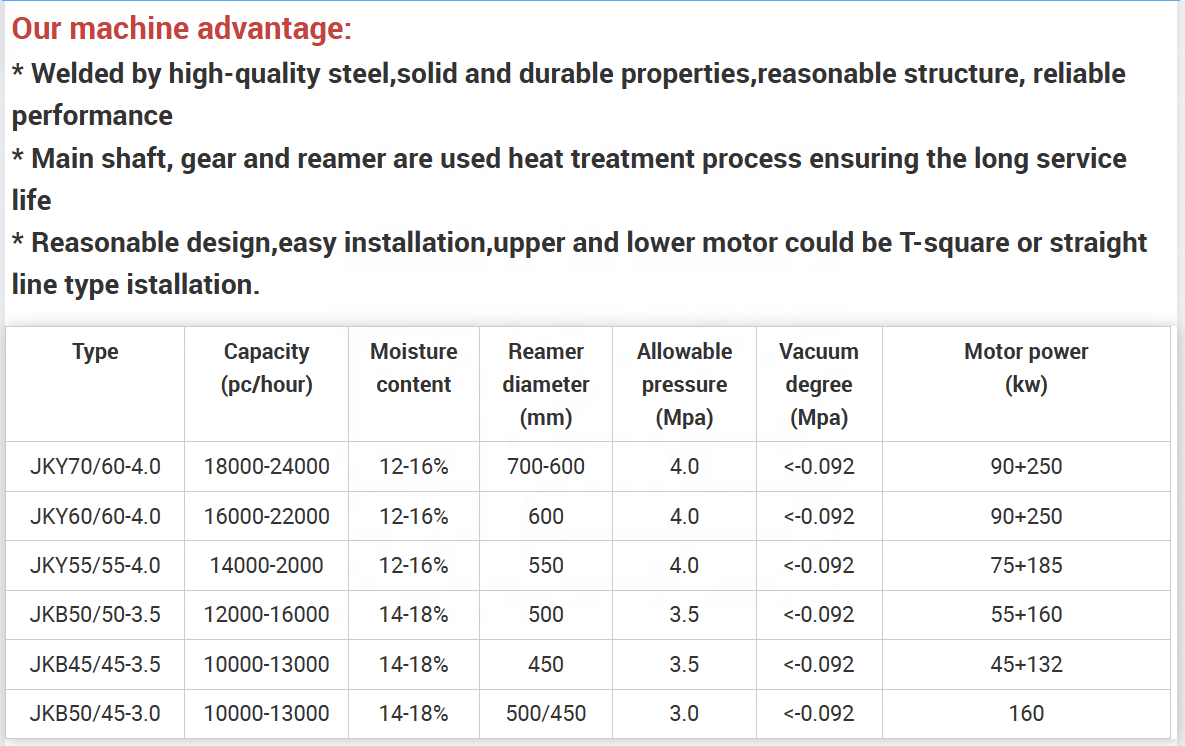

Our machine advantage:

* Welded by high-quality steel,solid and durable properties,reasonable structure, reliable performance

* Main shaft, gear and reamer are used heat treatment process ensuring the long service life

* Reasonable design,easy installation,upper and lower motor could be T-square or straight line type istallation.

Technical Parameters

|

Type

|

Capacity

(pc/hour)

|

Moisture

content

|

Reamer

diameter

(mm)

|

Allowable pressure

(Mpa)

|

Vacuum

degree

(Mpa)

|

Motor power

(kw)

|

|

JKY70/60-4.0

|

18000-24000

|

12-16%

|

700-600

|

4.0

|

<-0.092

|

90+250

|

|

JKY60/60-4.0

|

16000-22000

|

12-16%

|

600

|

4.0

|

<-0.092

|

90+250

|

|

JKY55/55-4.0

|

14000-20000

|

12-16%

|

550

|

4.0

|

<-0.092

|

75+185

|

|

JKB50/50-3.5

|

12000-16000

|

14-18%

|

500

|

3.5

|

<-0.092

|

55+160

|

|

JKB45/45-3.5

|

10000-13000

|

14-18%

|

450

|

3.5

|

<-0.092

|

45+132

|

|

JKB50/45-3.0

|

10000-14000

|

14-18%

|

500/450

|

3.0

|

<-0.092

|

160

|

We can customize different moulds to meet your requirement.

Other main machine

it's used to convey the raw materials to next procedure, can control the feeding speed,adjust the feeding capacity.

Roller crusher

It is used to further crush clay and other raw materials ≤ 2mm. Both ends of the crusher are equipped with secruity block, to

protect rolling circle and equipment.

protect rolling circle and equipment.

it's used to mix the crushed materials to enhance the comprehensive performance of materials.

strip cutter

it's used after extruder before blank cutter. after the mud is extruded, this cutter will cut it into certain length strips.

blank cutter

it's used to cut mud( which is squeezed from extruder) into qualified brick.use PLC control, pneumatic and electric servo systems,

having high accuracy, easy operation, simple maintenanc

having high accuracy, easy operation, simple maintenanc

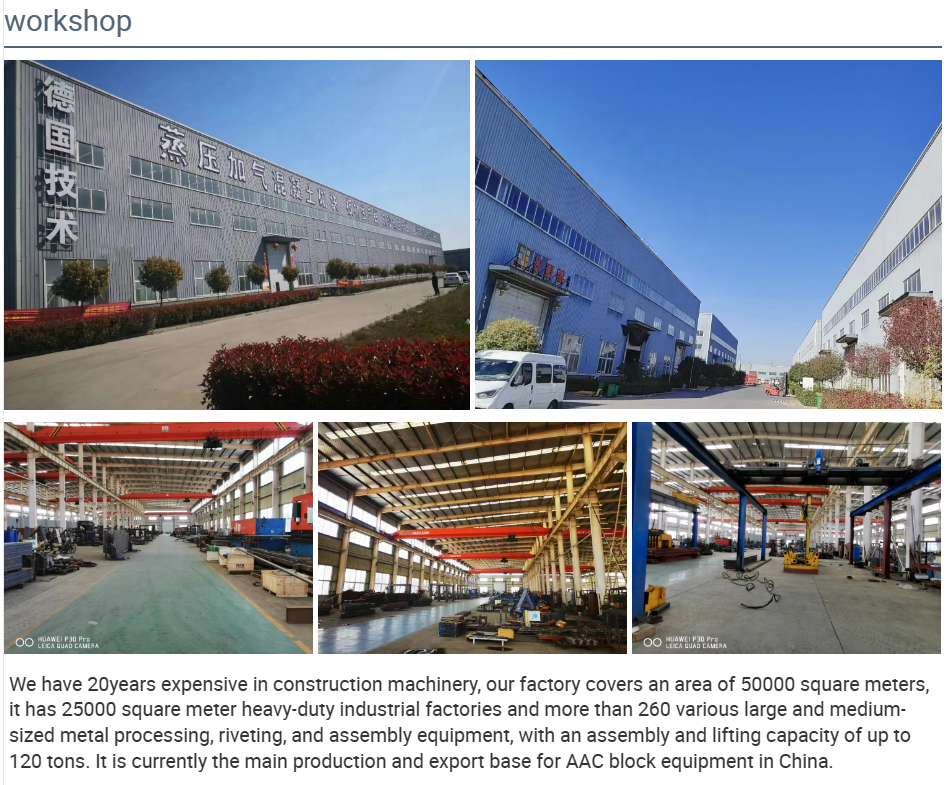

Our workshop

We have 20years expensive in construction machinery, our factory covers an area of 50000 square meters, it has 25000 square meter heavy-duty industrial factories and more than 260 various large and medium-sized metal processing, riveting, and assembly equipment, with an assembly and lifting capacity of up to 120 tons.For different equipment, we have dedicated production workshops with large scale and fast production speed, ensuring faster and more timely delivery of products .

Customer Visit

We has cooperated with more than 50 countries and received high reputation from our customer.We have won a good reputation among customers with good quality, competitive prices and advanced techniques since our establishment.

Packing & Delivery

a

fter testing the machine,

we will transport goods to qingdao port, ningbo port, shanghai port, shenzhen port, or guangzhou port, then load them into containers. After some days, customers will receive them.

We have a strict quality management system, meanwhile we also provide good after-sales service.

Our professional engineers can guide customer to install the machine oversea, adjust the machine and train the workers. Questions from all the customers, we all take it seriously and response timely.

Our Service

pre-sales service

*Professional suggestions(material matching,machine selection)

*Technical explanation

*visit our factory and working line

After-sales service

*Technical explanation

*visit our factory and working line

After-sales service

*lalyout and foundation design drawing

*Training how to install the machine and how to operatate

*engineers available to service machinery overseas

*technical support the whole using life.

*Training how to install the machine and how to operatate

*engineers available to service machinery overseas

*technical support the whole using life.

FAQ

Q1: Is this block machine suitable for us?

A: Could you please tell us what kind of bricks do you want to make? And the capacity you want? We will check if it can meet your request.

Q2:Which industry did this block machine usually be used in?

A:Hollow bricks, Solid bricks,etc

Q3:How to use the block machine?

A:We will send the operating manual to you after you purchase the machine, for bigger machine, we can offer engineer fly to yourside for installation and training your workers.

Q4:What's the after sale service of block machine?

A:1 year guarantee for the whole machine (without the spare parts).

Q5:what's your payment term?

A:less than 10000USD, pay in full; over 10000USD, 30%deposit by T/T before production, 70% balance before delivery.

Q2:Which industry did this block machine usually be used in?

A:Hollow bricks, Solid bricks,etc

Q3:How to use the block machine?

A:We will send the operating manual to you after you purchase the machine, for bigger machine, we can offer engineer fly to yourside for installation and training your workers.

Q4:What's the after sale service of block machine?

A:1 year guarantee for the whole machine (without the spare parts).

Q5:what's your payment term?

A:less than 10000USD, pay in full; over 10000USD, 30%deposit by T/T before production, 70% balance before delivery.

Hot Searches