- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Juren

-

Voltage:

-

380V/50Hz

-

Power:

-

48kw

-

Dimension(L*W*H):

-

12800*3230*1500mm

-

Weight:

-

2500 kg

-

Max Processing Size:

-

3660*2440mm

-

Qty of Layers:

-

2

-

Qty of Working Stations:

-

2

Quick Details

-

Machine Type:

-

Glass Laminating Machine

-

Glass Thickness:

-

3-12mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Juren

-

Voltage:

-

380V/50Hz

-

Power:

-

48kw

-

Dimension(L*W*H):

-

12800*3230*1500mm

-

Weight:

-

2500 kg

-

Max Processing Size:

-

3660*2440mm

-

Qty of Layers:

-

2

-

Qty of Working Stations:

-

2

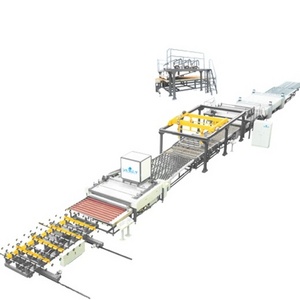

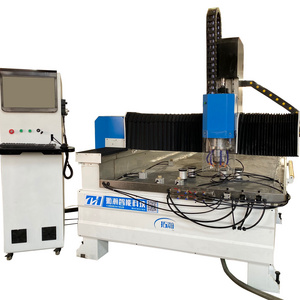

Juren Glass Laminating Machine Laminated Glass Making Furnace CNC Glass Processing Machinery More Stations Layers Optional

Product Description:

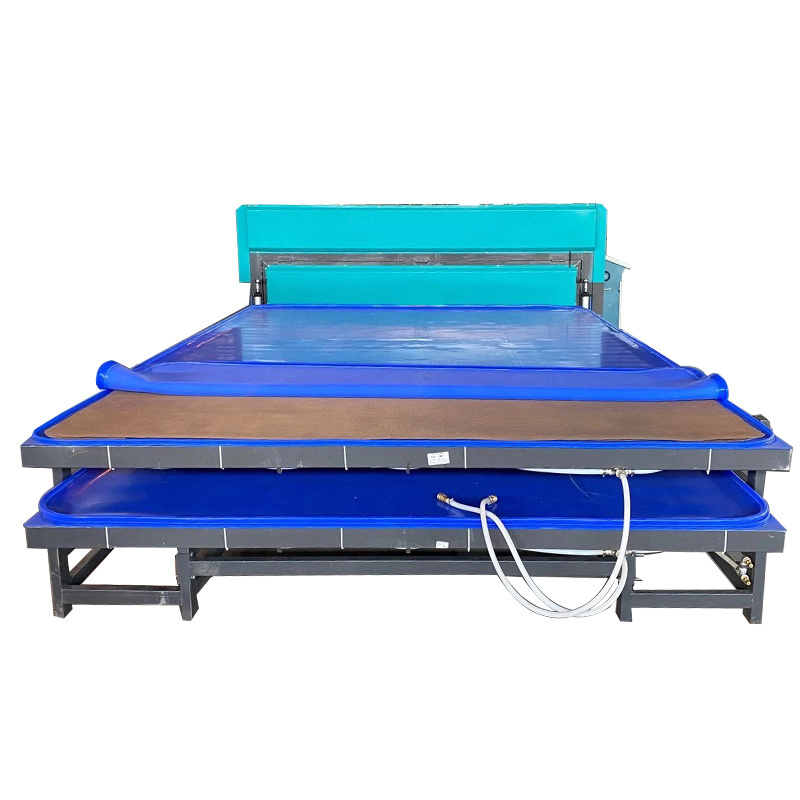

1. Multi-layer single station with hydraulic platform can be added, and single station with one, two or three layers can also be used.

If the capacity increased in the future, the equipment can be increased to double stations at any time (double stations are reserved when the equipment leaves the factory) .

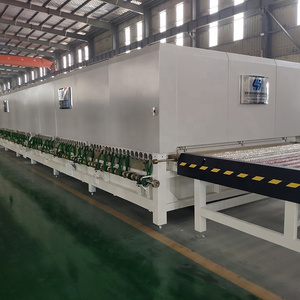

2. The heating system can achieve strong convective circulation of hot air through special turbofans, and can also realize 360° hot air circulation without dead angles, which represents the latest technology.

Through segmented partitions, the circulating air has no blind spots, uniform wind speed, equal air volume, and smooth circulation , u niform temperature .

3. It uses high-density explosion-proof stainless steel electric heating rods for heating, and is equipped with cold air supplement and hot air discharge devices through the patented technology of our owns.

The complement of cold and hot air makes up for the situation that traditional laminating furnaces cannot meet.

4. Its thermal insulation system has passed a large number of comparisons and simulations by engineers, and uses thick and high-density special materials for seamless butt processing. The double-layer thermal insulation system minimizes heat loss and saves more than 38% energy compared with similar products.

5. Multi-stage temperature control to prevent glue overflow. Each heating section of this equipment can change the negative pressure parameters as you need to achieve the purpose of preventing glue overflow .