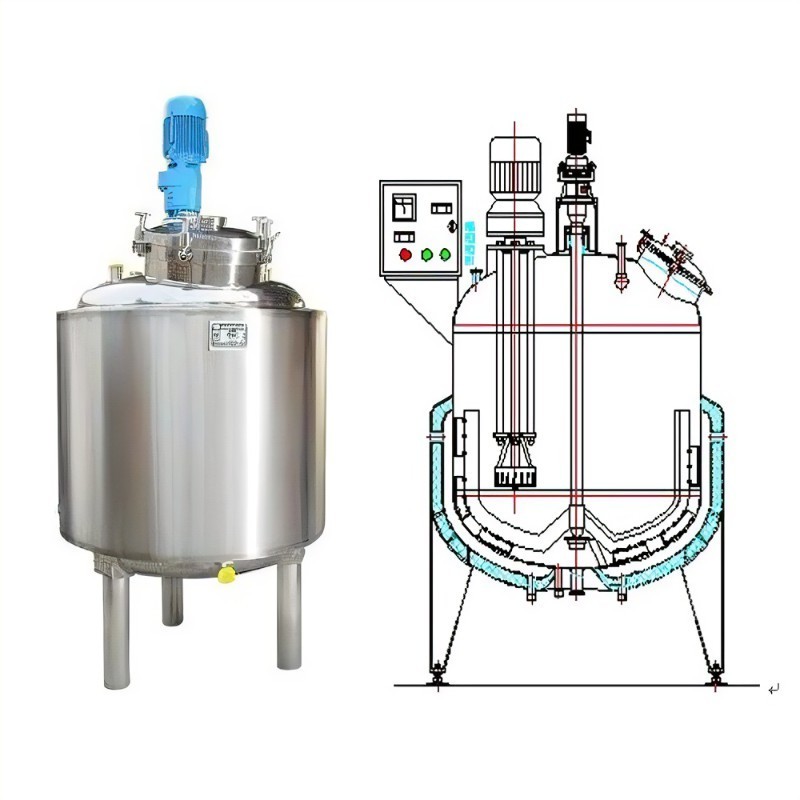

The stainless steel mixing tank body and the mixing tank cover can be connected by flange sealing or welding. The mixing tank body and the mixing tank cover can be opened with process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, safety venting, etc. according to the process requirements.

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

30000L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

China

-

Voltage:

-

120V/220V/380V/440V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

0.75 kW

-

Marketing Type:

-

Hot Product 2020

-

Product name:

-

Food Grade Stainless Steel Mixing Tank with Agitator for Beverage

-

Keyword:

-

Mixing Tank

-

Capacity:

-

50-30,000L

-

Speed control:

-

Inverter Frequency Control

-

Heating Method:

-

Steam/ Electric

-

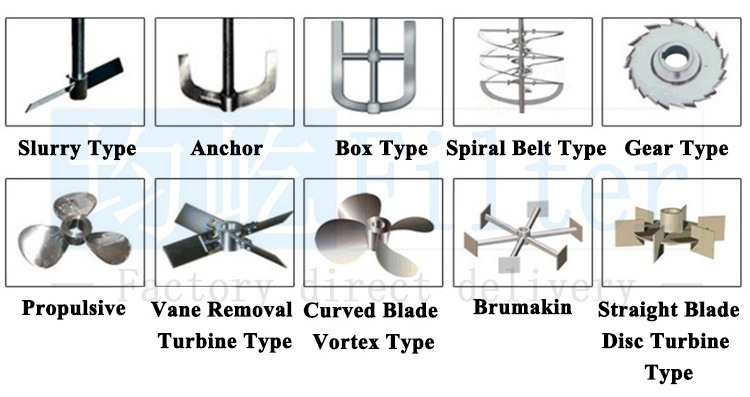

Mixing type:

-

Scraper Mixer Homogenizer Disperser

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

50000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 2800 r.p.m

-

Max. Loading Capacity:

-

30000L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

China

-

Voltage:

-

120V/220V/380V/440V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

0.75 kW

-

Marketing Type:

-

Hot Product 2020

-

Product name:

-

Food Grade Stainless Steel Mixing Tank with Agitator for Beverage

-

Keyword:

-

Mixing Tank

-

Capacity:

-

50-30,000L

-

Speed control:

-

Inverter Frequency Control

-

Heating Method:

-

Steam/ Electric

-

Mixing type:

-

Scraper Mixer Homogenizer Disperser

Product Overview

|

Stainless Steel Mixing Tank

|

|

|

|

Stainless steel mixing tank is mainly used for liquid-liquid mixing, solid-liquid mixing, gas-liquid mixing, so as to achieve full mixing, reaction, suspension, heat transfer and other purposes.

The structure and configuration of the stainless steel mixing tank can be standardized and humanized according to the requirements of the production process. During the mixing process, the feeding control, discharging control, mixing control and other manual and automatic control can be realized.

|

|

|

PRODUCT CONFIGURATION

Stainless steel mixing tank is composed of

mixing tank body

,

mixing tank cover

,

agitator

,

support

,

transmission device

,

shaft seal device

, etc. Heating device or cooling device can also be configured according to process requirements.

PRODUCT SPECIFICATIONS

|

Model

|

Effective Volume

L

|

Diameter of Tank

Φ*H

|

Total Volume

L

|

|

JY-50

|

50

|

Φ400*500

|

86

|

|

JY-100

|

100

|

Φ500*600

|

160

|

|

JY-200

|

200

|

Φ600*700

|

270

|

|

JY-300

|

300

|

Φ700*800

|

420

|

|

JY-500

|

500

|

Φ900*1000

|

660

|

|

JY-1000

|

1000

|

Φ1000*1200

|

1240

|

|

JY-1200

|

1200

|

Φ1000*1500

|

1480

|

|

JY-1500

|

1500

|

Φ1200*1500

|

2200

|

|

JY-2000

|

2000

|

Φ1400*1500

|

3100

|

|

JY-3000

|

3000

|

Φ1400*2000

|

3800

|

|

JY-4000

|

4000

|

Φ1600*2000

|

5200

|

|

JY-5000

|

5000

|

Φ1600*2500

|

6200

|

|

JY-8000

|

8000

|

Φ2000*2500

|

10000

|

Product Aplication

It is widely used in coatings, medicine, building materials, chemicals, pigments, resins, food, scientific research and other industries. The equipment can be made of carbon steel, stainless steel and other materials a ccording to the process requirements of users' products, as well as heating and cooling devices to meet different process and production needs. Heating forms include jacket electric heating, coil heating, steam heating, etc.

Packing & Delivery

Hot Searches