- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18-25kw/h

-

Dimension(L*W*H):

-

2500mm*8800mm

-

Weight:

-

90000 kg

-

Structure:

-

Horizontal Rotation Type

-

Capacity for one batch:

-

5-6 Mt

-

Fuels Choice:

-

Coal, Wood, Gas, Oil

-

Pressure:

-

Normal Pressure

-

Heating Method:

-

Indirect Direct

-

Cooling Mode:

-

Water Cooling

-

Feature:

-

crude oil process plant

-

Installation Space Required:

-

35x15m

-

Operating Mode:

-

Semi-continuous Operation

-

End Product:

-

Non-standard Diesel Oil

-

Certification:

-

CE SGS ISO BV TUV

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shangqiu jinpeng

-

Voltage:

-

380v

-

Power:

-

18-25kw/h

-

Dimension(L*W*H):

-

2500mm*8800mm

-

Weight:

-

90000 kg

-

Structure:

-

Horizontal Rotation Type

-

Capacity for one batch:

-

5-6 Mt

-

Fuels Choice:

-

Coal, Wood, Gas, Oil

-

Pressure:

-

Normal Pressure

-

Heating Method:

-

Indirect Direct

-

Cooling Mode:

-

Water Cooling

-

Feature:

-

crude oil process plant

-

Installation Space Required:

-

35x15m

-

Operating Mode:

-

Semi-continuous Operation

-

End Product:

-

Non-standard Diesel Oil

-

Certification:

-

CE SGS ISO BV TUV

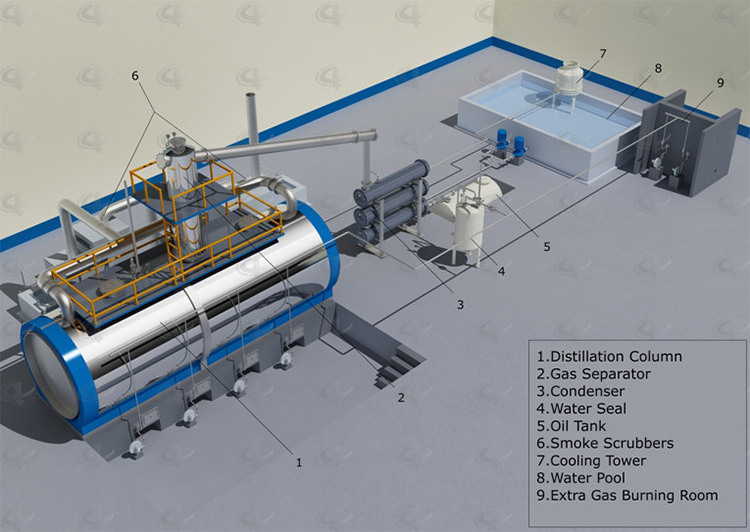

Products Description

Advantages of Distillation Plant

1). Security:

A. Adopting automatic submerged-arc welding technology and all of the weldings will be detected

by the ultrasonic nondestructive testing method.

B. Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, operators, etc.

C. Manual and automatic safety devices include:anti-explosion device, safety valves, emergency

valves, pressure and temperature meters, as well as the alarming system.

2). Environment-friendly:

A. Emission Standard: Sync Gas Recycling System: Fully burned after recycling and utilization,

saving fuel and preventing pollution. National Patent Smoke Scrubbers: water film smoke

scrubber, efficient removal of the acid gas and dust of the smoke, environmental friendly to

meet related national standards.

B. Smell during operation: Fully enclosed during the operation

C. Water pollution: During the operation, the water we use is recycling one to cool down the gas

oil and convert into liquid oil in the condensers. No pollution at all.

3). National Patent, unique heat insulation shell: high efficiency temperature keeping, excellent

energy-saving effect.

4). Semi-continuous operation, less manpower and low lost in operation.

5). Unique horizontal design, high oil output with about 90% oil yield and 100% conversion rate,

highly effective and profitable.

A. Adopting automatic submerged-arc welding technology and all of the weldings will be detected

by the ultrasonic nondestructive testing method.

B. Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, operators, etc.

C. Manual and automatic safety devices include:anti-explosion device, safety valves, emergency

valves, pressure and temperature meters, as well as the alarming system.

2). Environment-friendly:

A. Emission Standard: Sync Gas Recycling System: Fully burned after recycling and utilization,

saving fuel and preventing pollution. National Patent Smoke Scrubbers: water film smoke

scrubber, efficient removal of the acid gas and dust of the smoke, environmental friendly to

meet related national standards.

B. Smell during operation: Fully enclosed during the operation

C. Water pollution: During the operation, the water we use is recycling one to cool down the gas

oil and convert into liquid oil in the condensers. No pollution at all.

3). National Patent, unique heat insulation shell: high efficiency temperature keeping, excellent

energy-saving effect.

4). Semi-continuous operation, less manpower and low lost in operation.

5). Unique horizontal design, high oil output with about 90% oil yield and 100% conversion rate,

highly effective and profitable.

|

Item

|

Non-standard diesel

|

Standard

|

|

Oxidation Stability

|

2.2

|

≤2.5 mg/100ml

|

|

Sulfur Content (%)

|

0.3

|

M/m ≤0.2

|

|

10% Steamed Residual Carbon Residue (%)

|

0.33

|

M/m ≤0.3

|

|

Ash Content (%)

|

0.16

|

%m/m ≤0.01

|

|

Moisture Content (%)

|

Traces

|

/

|

|

Mechanical Impurities

|

/

|

/

|

|

Density (g/ml)

|

0.85

|

0.83-o.87

|

|

Solidifying Point/℃

|

-10

|

0

|

|

Flash Point (closed)/ ℃

|

45

|

55

|

|

Movement Viscosity

|

3.5

|

(20℃)mm2/s3.0-8.0

|

|

Combustion Value (kcal)

|

9500

|

8500

|

|

Colority

|

1.2

|

≤3.5

|

|

Cetane Number

|

40

|

45

|

|

Acidity

|

/

|

Mgkoh/100ml≤7

|

Note: These parameters of the oil will be different because the raw materials is different.

Successful Cases

Product packaging

Hot Searches