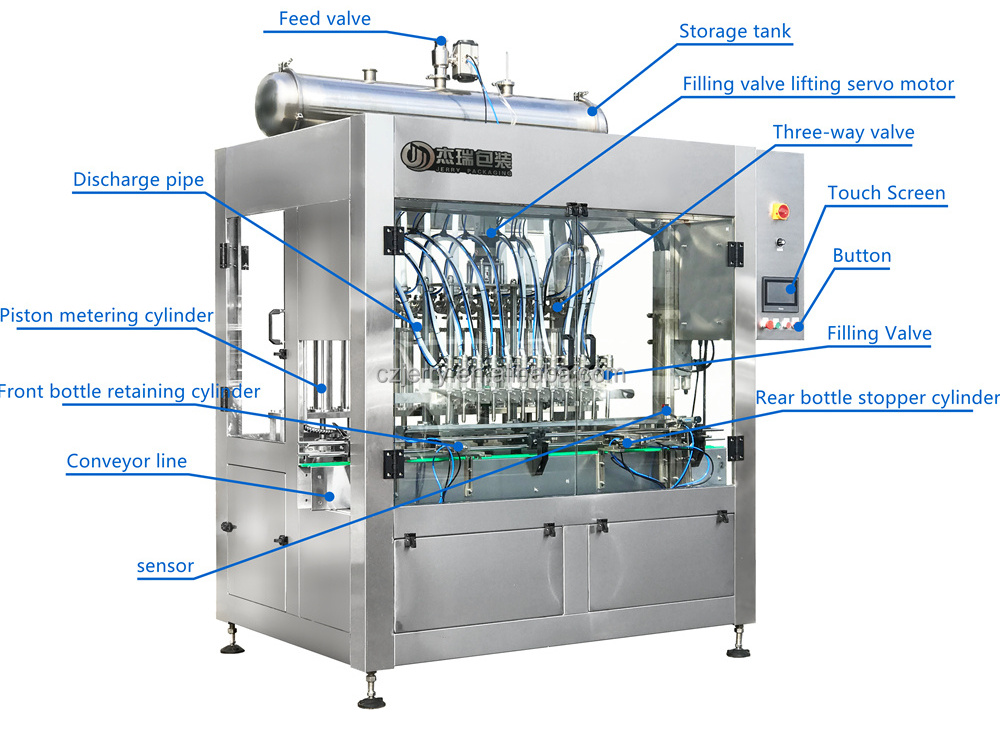

JPF Series intelligent high-viscosity filling machine is suitable for packaging of non-viscosity and high-viscosity materials.The whole machine has an in-line structure, and the principle of servo motor-driven filling and volumetric filling is used to achieve high accuracy of the filling dose. Optional high-precision electronic scale automatic weighing data transmission system for faster dose adjustment.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jerry pack

-

Dimension(L*W*H):

-

2000*1300*2200

-

Weight:

-

600 KG

-

Product name:

-

Piston Filling Machine

-

Function:

-

Automatic Filler

-

Filling volume:

-

50ml-1000ml 100ML-2000ML 1000ML-5000ML

-

Feature:

-

Servo control

-

Material:

-

Stainless Steel 304/316

-

Filling nozzles:

-

2/4/6/8/12/16/20/32

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jerry pack

-

Dimension(L*W*H):

-

2000*1300*2200

-

Weight:

-

600 KG

-

Product name:

-

Piston Filling Machine

-

Function:

-

Automatic Filler

-

Filling volume:

-

50ml-1000ml 100ML-2000ML 1000ML-5000ML

-

Feature:

-

Servo control

-

Material:

-

Stainless Steel 304/316

-

Filling nozzles:

-

2/4/6/8/12/16/20/32

Products Description

JPF Series Automatic Piston Filling Machine

Product Application

Product Features

Filling Nozzles

1.The filling valve adopts high-quality anti-drip filling valve. And it is equipped with a liquid receiving tray to ensure that the liquid will not drip onto the bottle.

2.The length and diameter of the filling nozzle will be matched with a suitable filling valve according to the customer's product size. 3.The number of filling heads will be customized according to the customer's product output requirements.

2/4/6/8/12/16/20/32 filling heads option

Piston Cylinder

1.Use 316 stainless steel piston cylinder.

1L,2L,5L option

2.It can fill a variety of liquids, viscous materials, and is widely applicable.

3.It is driven by Panasonic servo motor to ensure the accuracy of filling.

Servo motor of filling nozzle

For easy foaming liquid, we use Panasonic servo motor to control the filling nozzle up and down.The nozzle can diving into the bottle bottom and up with the liquid together.

Touch Screen

Adopt PLC control and touch human-machine interface, the whole machine is convenient and intuitive to operate.

Chinese and English interface.(Other

language can be

specified

)

Servo driven

The principle of servo motor-driven filling and volumetric filling is used to achieve high accuracy of the filling dose.

Technical Parameters

|

Filling head

|

12 heads((can be customized 2/4/6/8/12/16/20/32))

|

|

|

|

|||

|

Filling volume

|

50ml-1000ml/100ml-2000ml/1000ml-5000ml

|

100ml-2000ml

|

1000ml-5000ml

|

|

|||

|

Production Capacity

|

3500-4000BPH(Based on 12 filling nozzles,1L/bottle)

|

|

|

|

|||

|

Supply Voltage

|

220V, 50-60Hz, 1 Phase

|

|

|

|

|||

|

Power Consumption

|

2Kw

|

|

|

|

|||

|

Air Pressure

|

0.4-0.6Mpa

|

|

|

|

|||

|

Machine Dimension

|

(L)2000mm X (W)1050mm X (H)1970mm

|

|

|

|

|||

|

Machine weight

|

650kg

|

|

|

|

|||

Recommend Products

Automatic Filling Production Line

Bottle unscrambler-Filling-Capping-Labeling-Date printer-Case packing-Palletizer

Why Choose JERRY PACK

Changzhou Jerry Packaging Technology Co., Ltd. is specializing in packaging machinery R & D, manufacturing and sales.Our liquid bottle packaging technology is most advanced in China.All products are in accordance with the national "GMP" standard. The advanced design concepts and professional technology has been a prominent feature of Jerry Packaging Technology.We have perfect manufacturing system. We manage service after sale strictly and considerately.Jerry Packaging Technology has won a good reputation in the area.

OUR FACTORY

OUR TEAM

INTERNATIONAL EXHIBITION

OUR MACHINE IN CUSTOMER

OUR COMPONENT

SUPPLIERS

QC & INSPECTION

THROUGH WHOLE PRODUCTION PROCESS

ALL RAW MATERIALS

ALL PARTS

ALL COMPONENTS

Our Service

OUR SERVICES

For All Your Packaging Needs

Packaging line design and consultation

Factory acceptance testing

Installation, startup, and training

Free technical online support

Field service and preventative maintenance

24 hours online service:

+86 13616137022

penny@jpacks.com

FAQ

Q1: Are you factory or trading company?

A: We are factory or manufacturer.

Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.

Q4: How could I get the spares on machines?

A:We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.

Q5: Is there any insurance which I pay for to guarantee I will get the right machine?

A: We are an onsite check supplier from Alibaba. Trade Assurance provides quality protection, ontime shipment protection and 100% safe payment protection. Our factory already highest stars of the grade.

Q6.What's the payment terms and trade terms for new customers?

A: Payment terms:30% T/T DEPOSIT PAYMENT IN ADVANCE,BALANCE 70% AGAINST COPY OF B/L.WESTERN UNION,LC ARE ACCEPTABLE.

Q7:What's the Minimum Order Quantity and warranty?

A:MOQ:1 set Warranty:12 months,some customized products will be 24 months.

Q8:Do I need to pay for the extra cost like tax or duty ?

A:It is the buyers' responsibility to pay the custom duty.The shipping fee will not include the tax,please pay attention to this.

Hot Searches