- Product Details

- {{item.text}}

Quick Details

-

Rolling Speed (m/min):

-

0.5 - 4

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Supertech

-

Year:

-

2022

-

Weight (KG):

-

10000 KG

-

Motor Power (kw):

-

37 kw

-

After-sales Service Provided:

-

yes

-

Raw Material:

-

Sheet

-

Voltag:

-

customzied

-

Color:

-

Customizable

-

Model:

-

up to plate

-

Controller:

-

Cnc Auotomatic

-

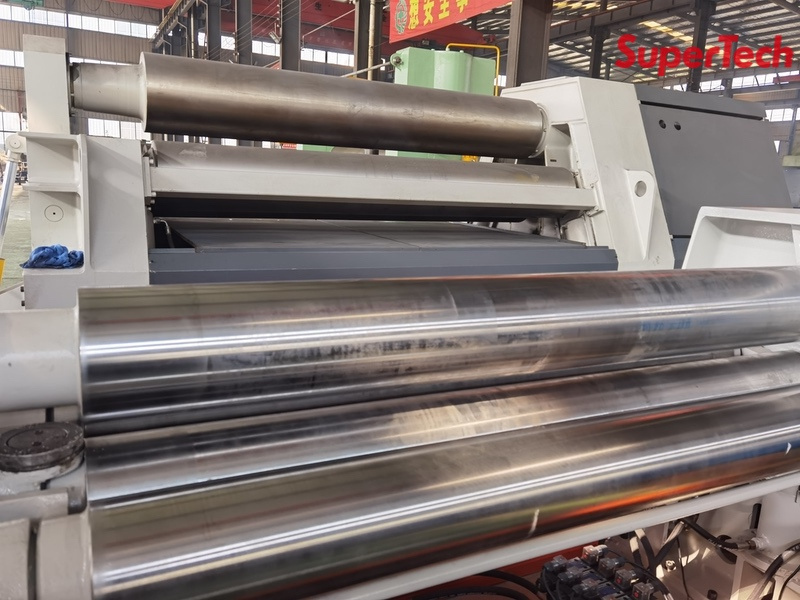

TOP roller diameter(mm):

-

from 175mm

Quick Details

-

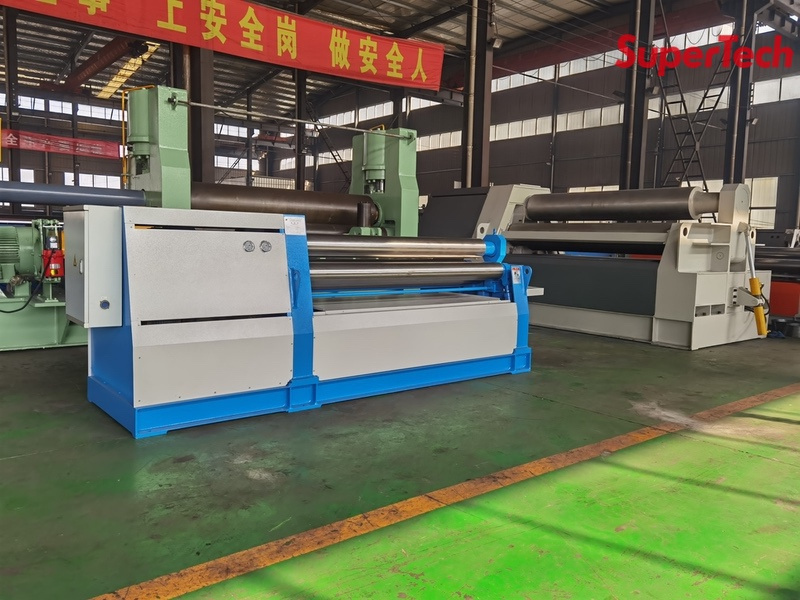

Max. Working Length (mm):

-

6000 mm

-

Max. Plate Thickness (mm):

-

150 mm

-

No. of Roller:

-

4

-

Rolling Speed (m/min):

-

0.5 - 4

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Supertech

-

Year:

-

2022

-

Weight (KG):

-

10000 KG

-

Motor Power (kw):

-

37 kw

-

After-sales Service Provided:

-

yes

-

Raw Material:

-

Sheet

-

Voltag:

-

customzied

-

Color:

-

Customizable

-

Model:

-

up to plate

-

Controller:

-

Cnc Auotomatic

-

TOP roller diameter(mm):

-

from 175mm

Production Description

|

W12 FOUR ROLLERS BENDING

|

W11 MECHANICAL ROLL MACHINE

|

W11S UNIVERSAL UPPER ROLLER

|

|

Down roller clamp the plate, side rollers forming degree for the plate, upper roller rolling and forming pipes.

|

upper roller clamp the plate, and forming the plate degree with distance of side rollers, rolling and forming pipe.

|

upper roller clamp and roll, side rollers move left and right together, to form the degree, rolling pipe.

|

Product Details

Vertical Support

It’s formed with a movable support. This part can move up and down to suit the diameter of rolling workpiece and provide the

support for the rolling drum. To make it stable and strong, we must make a strong hole on the foundation to set the anchorage point like

the photo.

The support is also controlled by hydraulic system and electric system, focused on the control table.

The feeding table is composed by small rollers, motors, reducers, hydraulic cylinders and so on, used for the support and feeding

of rolling material.

The cone roller is at the end of down upper, with prepared cone making plate, it can roll cones directly. All W12, W11, W11S can add this function

Hot Searches