- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Steelmaking,Electric Arc Furnace

-

Special Pipe:

-

Calorised and Ceramic coated

-

Outer Diameter:

-

10 - 60 mm

-

Thickness:

-

1 - 3 mm

-

Grade:

-

Carbon Steel, Q215

-

Name:

-

Calorised and Ceramic coated oxygen lancing pipe

-

Material:

-

Q235

-

Type:

-

welded steel pipe

-

Secondary Or Not:

-

Non-secondary

-

Certification:

-

ISO9001

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Calorised and Ceramic coated

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Steelmaking,Electric Arc Furnace

-

Special Pipe:

-

Calorised and Ceramic coated

-

Outer Diameter:

-

10 - 60 mm

-

Thickness:

-

1 - 3 mm

-

Grade:

-

Carbon Steel, Q215

-

Name:

-

Calorised and Ceramic coated oxygen lancing pipe

-

Material:

-

Q235

-

Type:

-

welded steel pipe

-

Secondary Or Not:

-

Non-secondary

-

Certification:

-

ISO9001

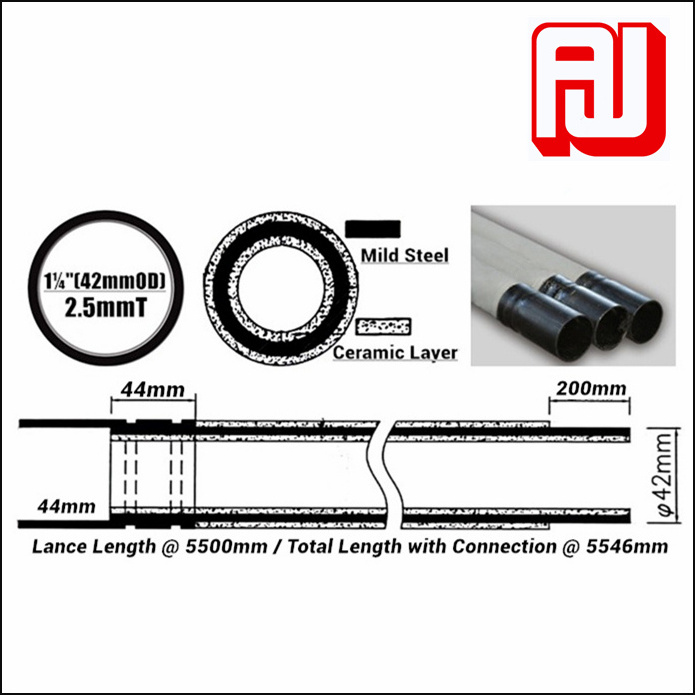

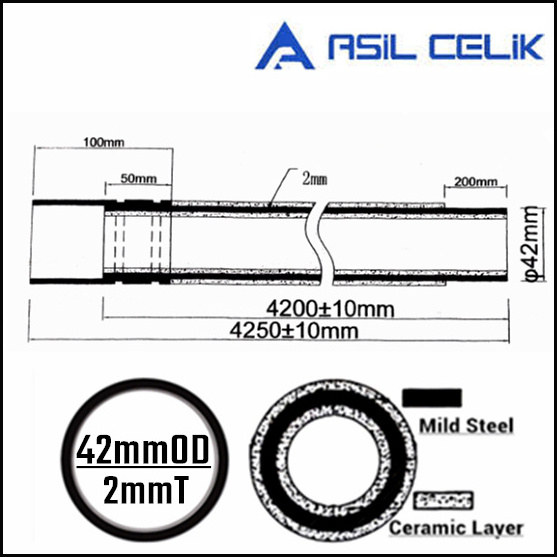

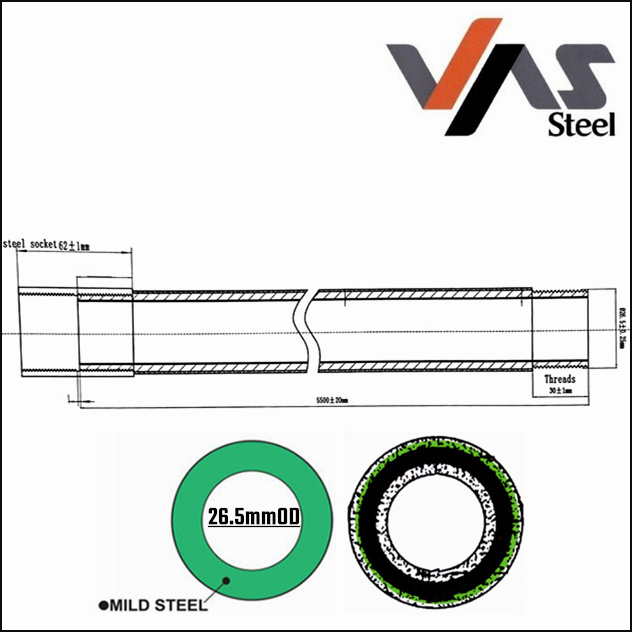

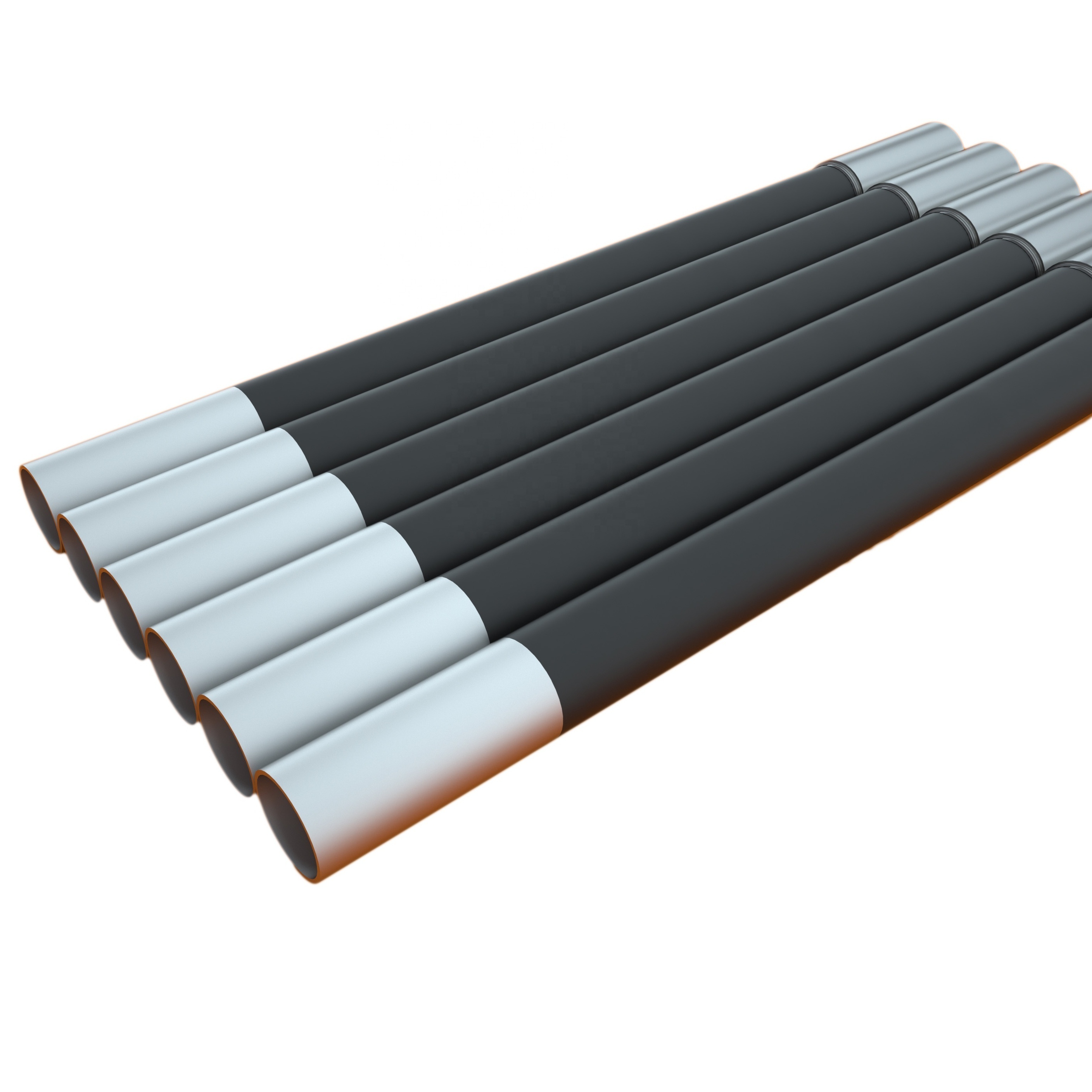

Calorised & Ceramic Coated Oxygen Lance pipe

Calorised and Ceramic Coated oxygen lance pipe used a low carbon special thin walled pipe, which is calorized and coated with ceramic materials on both the inner and outer surfaces. In steelmaking, pipes are used for oxygen injection and under this high temperature and severe environment, normal steel pipes that are used as lance will be consumed fast. When using Calorised Ceramic Coated Lance, the consumption rate will improve 6-7 times.

Advantages

1)

Minimum Consumption

The calorized layer and the refractory caoting layer together generate the strong heat resistance and anti-oxidation to achieve minimum consumption of lance pipe to cut down your cost.

2)Superior Quality Strict quality control is made at each production process over the raw materials to the finished products.

3) Economical price Low price with high quality is achieved through madd production at our most advanced factory.

|

Product Name

|

Calorised & Ceramic coated Oxygen Lance Pipe

|

|

Material

|

Carbon Steel

|

|

End protector

|

Plastic Pipe Cap

|

|

Size

|

Customized

|

|

Application

|

Steel Making

Electric Arc Furnace

Smelting

Carbon Powder/ Oxygen Injection

|

|

INCH

|

OD

|

MM

|

Connection

|

|

|

LENGTHS

|

COATING THICKNESS

|

||

|

|

|

|

PLAIN

|

PRESS ON COUPLING

|

THREADED & Socket

|

|

|

||

|

1/2''

|

0.85‘’

|

21.4

|

YES

|

YES

|

YES

|

9' & 18'

|

350 gal/avg

|

||

|

3/4''

|

1.05''

|

26.7

|

YES

|

YES

|

YES

|

9' & 18'

|

350 gal/avg

|

||

|

1''

|

1.315''

|

33.4

|

YES

|

YES

|

YES

|

9' & 18'

|

400 gal/avg

|

||

|

1 1/4''

|

1.660''

|

42

|

YES

|

YES

|

YES

|

9' & 18'

|

450 gal/avg

|

||

|

1 1/2''

|

1.900

|

48

|

YES

|

YES

|

YES

|

9' & 18'

|

450 gal/avg

|

||

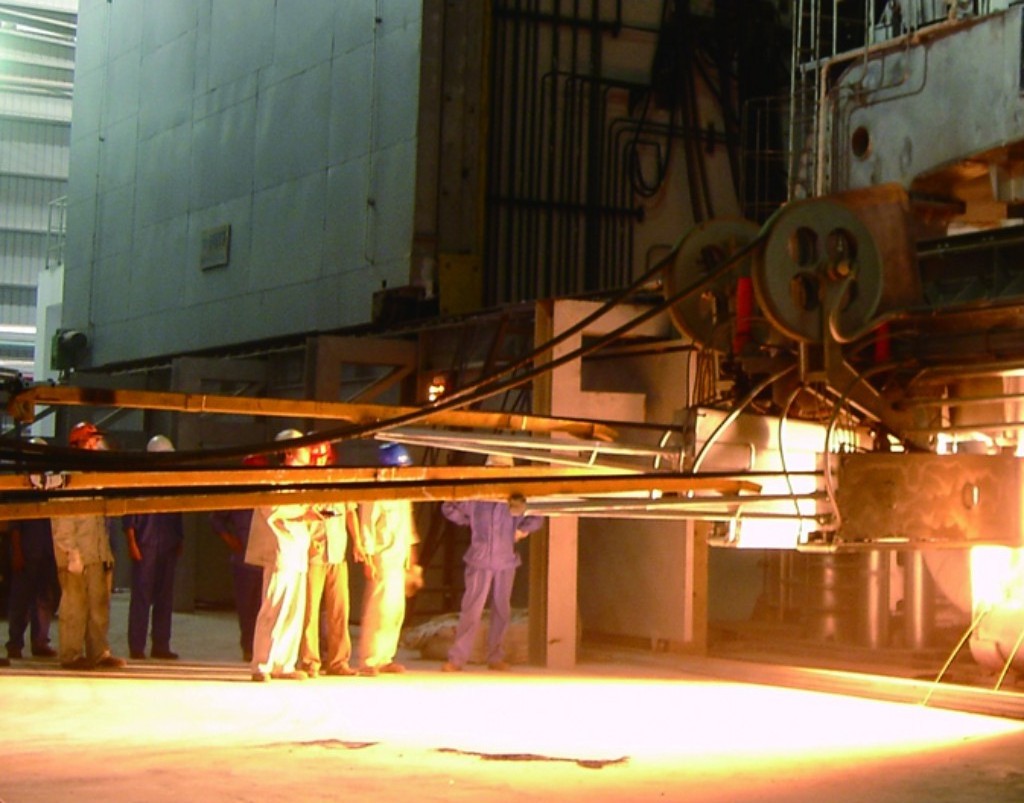

Application of Cupola Furnace Usage Welded Carbon Steel Pipe Oxygen Lance

1)Cutting steel scarp, melting and refining steel at electric arc furnace.

2)Injection of carbon, lime poeder and/or other additives for adjusting grades of carbon steel or special steel.

3)Removing slag inside oxygen converter.

4)Other uses which require strong resistance aganist heat, oxidation, sulfuration, vanadium attack, etc.

STRAPPED BUNDLE WRAPPED IN PLASTIC