- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V / 380V

-

Power:

-

4KW

-

Weight:

-

150 KG

-

Dimension(L*W*H):

-

960*650*1550mm

-

Application:

-

Food,Seeds, Grain

-

Milling Type:

-

Rotary Wheel

-

Powder Fineness:

-

20-100 Mesh

-

Material:

-

Stainless Steel 304

-

Certification:

-

CE

-

Raw material:

-

Wheat Maize Corn

-

Final products:

-

Super Fine Maize Flour

-

Processing type:

-

Single Cowpea Flour Grinder Machine

-

Processing:

-

Complete Cleaning-Degermining-Milling-Packing

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TOPSPACK

-

Production Capacity:

-

60-100KG/h

-

Voltage:

-

220V / 380V

-

Power:

-

4KW

-

Weight:

-

150 KG

-

Dimension(L*W*H):

-

960*650*1550mm

-

Application:

-

Food,Seeds, Grain

-

Milling Type:

-

Rotary Wheel

-

Powder Fineness:

-

20-100 Mesh

-

Material:

-

Stainless Steel 304

-

Certification:

-

CE

-

Raw material:

-

Wheat Maize Corn

-

Final products:

-

Super Fine Maize Flour

-

Processing type:

-

Single Cowpea Flour Grinder Machine

-

Processing:

-

Complete Cleaning-Degermining-Milling-Packing

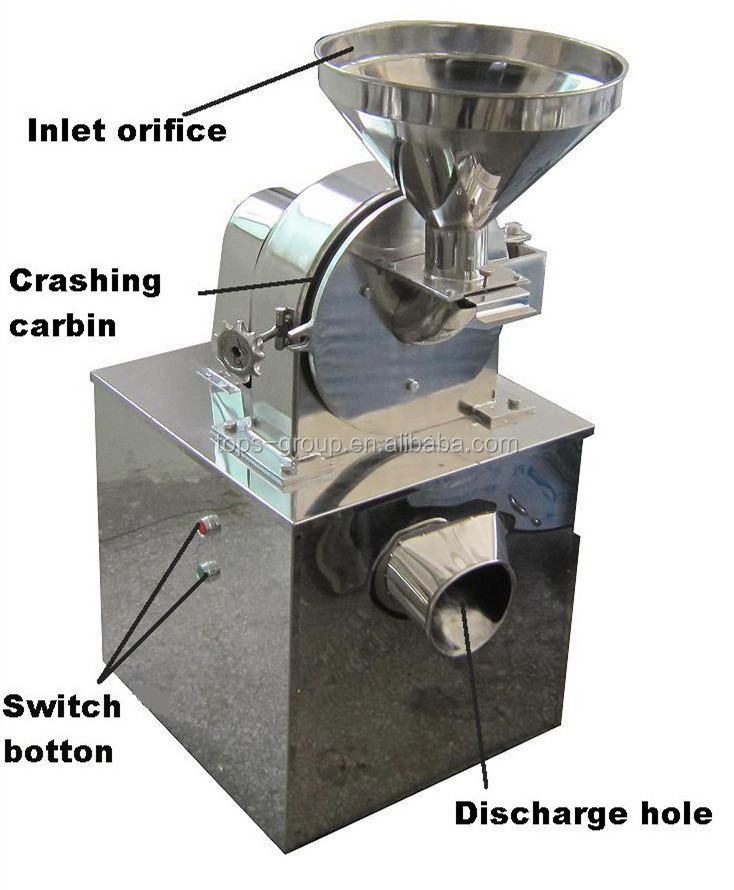

TOPSPACK food milling machine dry food grinder for rice flour

General description:

1.This grinder/miller is a high efficient machine. It is widely applied in food processing,chemical and industrial areas. It is a good equipment to help you in supermarkets,factories and home.

2.It's suitable to mill foodsuch as rice,wheat,sesame,corn,oat,spice,cocoa,almond, beans, grain, and chemical such as herb, polyethylene, PVC, polystyrene, polyvinyl alcohol, limestone, gypsum, paints, pigments, especially for oily, viscous material. The materials wil be mill into powder,flour or starch in 20 minutes. The fineness is adjustable,from 10-120 mesh.

Main features:

1.Whole machine SUS 304 material,simple and strong, easy for washing.

2.N ot easy to get heat, for there is a large cooling space inside.

2.easy disassembly and cleaning

3. with dust collecting,no waste and low noise

Working Principle:

1. The raw material is sent into the machine hopper by the feeder conveyor, then leaks into the crashing cabin.

2. The leather belt driven by motor spurs the motional hammers whirling in a high speed, the hammers chafe, collide with the immovable fluted disc in a high speed, then the raw material is ground.

3. The ground powder will leaks from the screen stencil, gets out from the discharge hole, stored inside the bag.

Technical parameters:

|

Model |

TP-GM- 20B |

TP-GM -30B |

TP-GM- 40B |

TP-GM- 60B |

|

Capacity (kg / h) |

6 0- 1 00 |

1 00- 3 00 |

160-800 |

500-1500 |

|

Feed size (mm) |

< 6 |

< 10 |

< 12 |

< 1 5 |

|

Grinding fineness (mesh) |

10 -1 2 0 |

|||

|

Spindle speed (r / min) |

4500 |

3800 |

3400 |

2800 |

|

Motor Power (k w) |

4 |

5.5 |

7.5 |

11 |

|

Weight (kg) |

150 |

250 |

380 |

550 |

|

Dimensions(mm) |

960* 6 50*15 5 0 |

10 00× 65 0×1 550 |

1200× 75 0× 168 0 |

1350×750×1680 |

|

Screen hole size |

Standard mesh |

Screen hole size |

Standard mesh |

|

1.70mm |

12mesh |

0.425mm |

40mesh |

|

1.40mm |

14mesh |

0.355mm |

45mesh |

|

1.18mm |

16mesh |

0.300mm |

50mesh |

|

1.00mm |

18mesh |

0.250mm |

60mesh |

|

0.850mm |

20mesh |

0.212mm |

70mesh |

|

0.710mm |

25mesh |

0.180mm |

80mesh |

|

0.600mm |

30mesh |

0.150mm |

100mesh |

|

0.500mm |

35mesh |

0.125mm |

120mesh |

Pictrue in detail:

Product sample:

Our company:

Our Promise:

Top and consistent quality, Reliable and excellent after-sale service!