- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Brand Name:

-

WB

-

Dimension(L*W*H):

-

2000*1500*1600mm

-

Weight:

-

400 KG

-

filling volume:

-

50-500ml

-

production capacity:

-

20-40 bottles/min

-

filling accuracy::

-

≤±1%

-

filling head number::

-

4

-

machine body::

-

304 stainless steel

-

pass rate:

-

≥ 98%

-

Power supply:

-

1Ph.220V 50/60Hz

-

operate pannel:

-

touch screen

-

Product name:

-

WB-YG4

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Brand Name:

-

WB

-

Dimension(L*W*H):

-

2000*1500*1600mm

-

Weight:

-

400 KG

-

filling volume:

-

50-500ml

-

production capacity:

-

20-40 bottles/min

-

filling accuracy::

-

≤±1%

-

filling head number::

-

4

-

machine body::

-

304 stainless steel

-

pass rate:

-

≥ 98%

-

Power supply:

-

1Ph.220V 50/60Hz

-

operate pannel:

-

touch screen

-

Product name:

-

WB-YG4

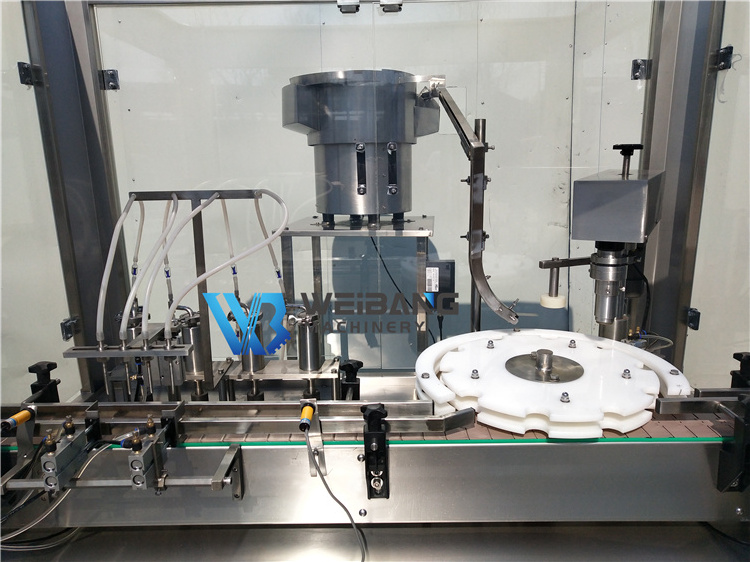

Details Images

WB-YG4 automatic

liquid

filling and capping machine

This machine is mainly used for

syrup

, honey,

juice

, wine,

drinks

, olive oil, essential oil, facial cleanser,

shower gel, hair oil, ink, laundry detergent and liquid filling and capping.

Sample

Function and features:

1.machine use plunger type metering pump filling(when the filling volume difference is large,the corresponding pump body needs to be replaced),high precision.

2.The structure of pump adopts fast disassembled mechanism,easy to clean and disinfect.

3.PLC control system ,color touch screen display,machine has function of counting automatically.

4.The filling nozzle was equipped with drop-proof device.

5. When filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly, it can effectively prevent the generation of bubbles.

6. Machine shell is made of 304 stainless steel,meets GMP standard.

1.machine use plunger type metering pump filling(when the filling volume difference is large,the corresponding pump body needs to be replaced),high precision.

2.The structure of pump adopts fast disassembled mechanism,easy to clean and disinfect.

3.PLC control system ,color touch screen display,machine has function of counting automatically.

4.The filling nozzle was equipped with drop-proof device.

5. When filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly, it can effectively prevent the generation of bubbles.

6. Machine shell is made of 304 stainless steel,meets GMP standard.

|

Customize nozzle number according to filling speed

|

|

|

|

|||

|

Model

|

WB-YG4

|

WB-YG6

|

WB-YG8

|

|||

|

Filing head number

|

4

|

6

|

8

|

|||

|

Adding cap head

|

1

|

2

|

2

|

|||

|

Capping head No.

|

1

|

2

|

2

|

|||

|

Filling volume

|

50-1000ml

|

50-1000ml

|

50-1000ml

|

|||

|

Capacity

|

5-35 bottles/min

|

10-60 bottles/min

|

15-70 bottles/min

|

|||

|

Filling accuracy

|

≤ ±1%(depend on product)

|

≤ ±1%(depend on product)

|

≤ ±1%(depend on product)

|

|||

|

Pass rate

|

≥ 98%

|

≥ 98%

|

≥ 98%

|

|||

|

Power supply

|

1 Ph. AC220V/3Ph AC380V 50/60Hz

|

1 Ph. AC220V/3Ph AC380V 50/60Hz

|

1 Ph. AC220V/3Ph AC380V 50/60Hz

|

|||

|

Total power

|

2.8 KW

|

3.0 KW

|

3.5KW

|

|||

|

Net weight

|

About 850kg

|

About 1000 kg

|

About 1200 kg

|

|||

|

Overall Dimension

|

L4600x W1800x H1900mm

|

L6500x W4800x H1900mm

|

L7000x W5200x H1900mm

|

|||

Machine details

WB-YG4 automatic syrup filling and capping machine

Filling part

Filling nozzle: The machine can be customized with

4/6/8/10/12 filling nozzles

according to the filling speed requirements.

Capping part

Customized according to cap.

Ordinary round plastic cap /aluminum cap

The machine can also be customized automatically add add cap. cap feeder

turn table

Food grade

Touch screen

Change filling volume

Piston pump

Servo motor control

Explosion-proof devices can be added

Recommend Products

PE/PP shrink film cutting and shrink wrapping machine

WB-LT100 automatic vertical labeling machine

WB-GP800 bottle feeder

WB-TP800 bottle collection table

Automatic carton box packing machine

Other filling machine in our factory. plastic bottle filling line

Automatic liquid filling and capping line

Contact us!

Company introduction

Hot Searches