- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customerized local voltage

-

Power:

-

50-80KW or Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

10000

-

Product name:

-

coating machine

-

Sample:

-

yes

-

Material:

-

SUS304

-

Technology:

-

Sputtering Coating

-

Application:

-

phone class and,touch screen,panel ,camera cover

-

Function:

-

Protective Film

-

Control System:

-

PLC+ touch screen

-

Ultimate:

-

3.0x10-4pa

-

Quality:

-

Super High Yield

-

Advantage:

-

High-efficiency

Quick Details

-

Machine Type:

-

pvd coating machine, Coating Equipment

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

HANA

-

Voltage:

-

customerized local voltage

-

Power:

-

50-80KW or Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

10000

-

Product name:

-

coating machine

-

Sample:

-

yes

-

Material:

-

SUS304

-

Technology:

-

Sputtering Coating

-

Application:

-

phone class and,touch screen,panel ,camera cover

-

Function:

-

Protective Film

-

Control System:

-

PLC+ touch screen

-

Ultimate:

-

3.0x10-4pa

-

Quality:

-

Super High Yield

-

Advantage:

-

High-efficiency

Products Description

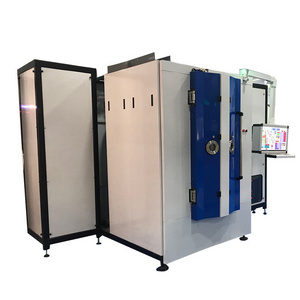

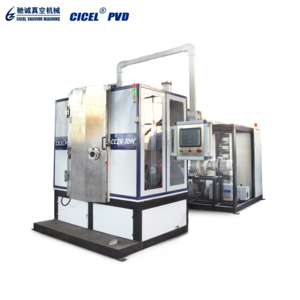

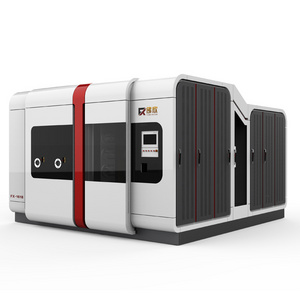

HANA Magnetron Sputtering Coating Equipment / PVD Coating Machine

Hana sputtering coating system is a multi-functional sputtering coating equipment for color coating, metalizing coating and AF, AR coating in the panel fields of mobile phones and automobiles. This equipment is single door structured with multiple target positions inside.

It can also do super thick film over 500 nm. The product hanger in the cavity is detachable and can rotate at a high speed of over 60 turns per min.

Advantages

1. 8 targets can be flexibly configured with material of the target.

2. Each target can be opened simultaneously or repeatedly according to the requirements.

3. Segmented gas distribution makes the film uniformity better.

4. The coating area that can be processed each chamber is large and high efficient.

5. Convenient operation and real-time monitoring data ensure the quality of the product.

6. The reasonable overall structure is convenient for operation and maintenance.

APPLICATION

Phone glass, touch panel, touch screen, phone shell/case, camera Cover, automotive lamp, accessories, logos, wheel hubs, etc

|

Model

|

VSD 1621

|

VSD 1821

|

VSD 2527

|

||

|

Dimension

|

1600X2100

|

1800x2100

|

2500x2700

|

||

|

Material

|

SUS304 stainless steel or carbon steel

|

|

|

||

|

Vacuum system

|

Rotary pump+Booster pump+Turbo pump (3.0*10-4Pa)

|

|

|

||

|

Working cycle

|

50-100minutes/chamber,7m2/chamber

|

|

|

||

|

Process power

|

Imported MF power supply

|

|

|

||

|

Cooling system

|

POLY cold unit( reaching under 130°C), CHILLER

|

|

|

||

|

Control system

|

PLC and one touch screen

|

|

|

||

|

Remark

|

All can be designed according to customer's requests.

|

|

|

||

Hot Searches