- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±5%

-

Voltage:

-

220V, 380V, 400V, 415V, 460V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2500 KG

-

Product name:

-

Aluminum can carbonated Filling Line

-

Filling material:

-

carbonated water/beverage/juice

-

Production capacity:

-

1500~24000BPH

-

After-sales Service Provided:

-

Engineers

-

suitable bottle:

-

50-110

-

Voltage::

-

220V, 380V, 400V, 415V, 460V, 3PH

-

Power:

-

9.2KW

-

Certification:

-

CE, ISO

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Beer, Water, Juice

-

Filling Accuracy:

-

±5%

-

Voltage:

-

220V, 380V, 400V, 415V, 460V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2500 KG

-

Product name:

-

Aluminum can carbonated Filling Line

-

Filling material:

-

carbonated water/beverage/juice

-

Production capacity:

-

1500~24000BPH

-

After-sales Service Provided:

-

Engineers

-

suitable bottle:

-

50-110

-

Voltage::

-

220V, 380V, 400V, 415V, 460V, 3PH

-

Power:

-

9.2KW

-

Certification:

-

CE, ISO

Products Description

It is suitable for filling and sealing aluminum canned beer and carbonated soft drinks. It is equipped the advanced device,

electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid

level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid

level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system. It is the preferred equipment for the medium beer and beverage plant.

Working Prodecure

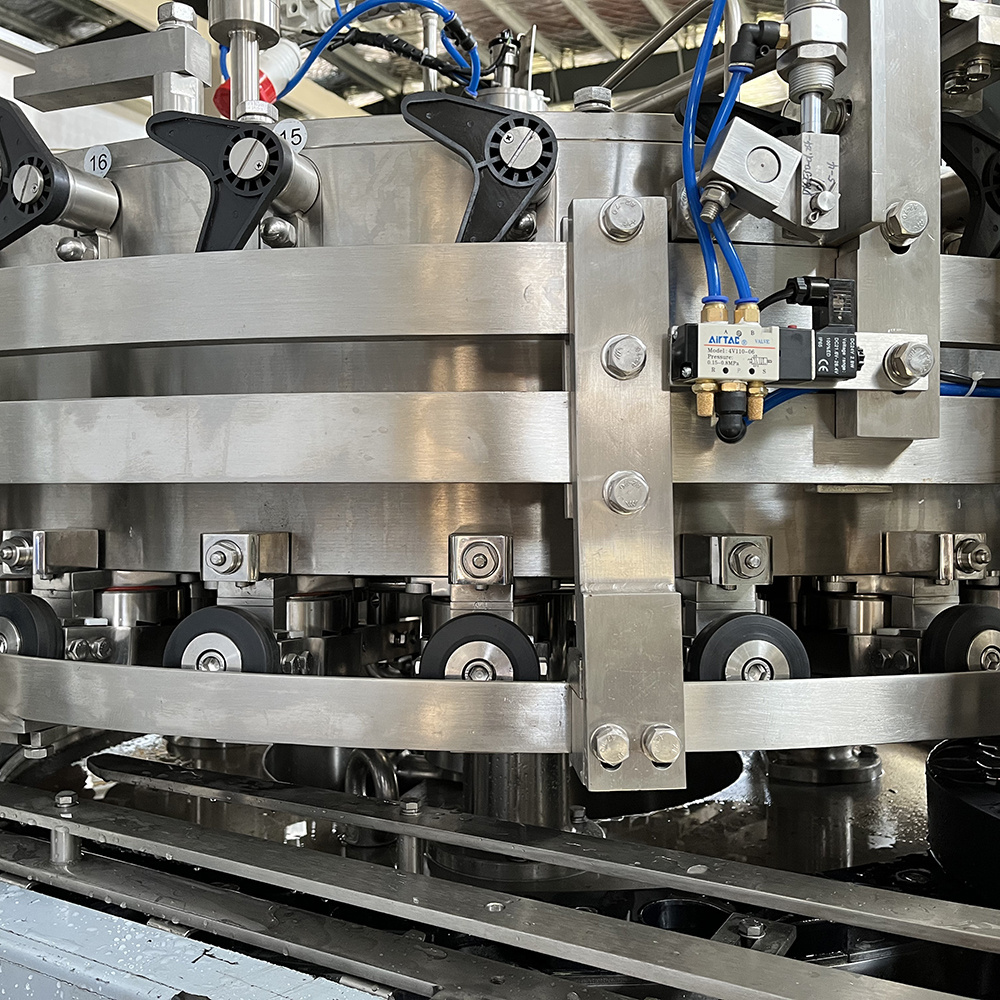

Can is pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed, air is discharged, and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to capper. Capper will take cap, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. After that can is transferred to conveying system.

Detailed Image:

Can Infeed

Seamer

Can outfeed

Configuration

|

1. PLC

|

Mitsubishi

|

|

2. Main motor

|

ABB

|

|

3. Pneumatic component

|

Airtac

|

|

4. Touch screen

|

Proface

|

|

5. Inverter

|

Mitsubishi

|

|

6. Breaker

|

Siemens or Schneider

|

|

7. Contactor

|

Siemens or Schneider

|

|

8. Proximity switch

|

Sick

|

|

9. Photoelectric switch

|

Sick

|

|

10. Lubrication bearing

|

Igus

|

Blowing / Filling / Combi / Container Treatment & Cleaning / Conveying Systems /

Labeling /

Packing / Palletising

1. Water treatment system purify water (Sand filter,carbon filter,RO/UF ,Ozone sterilizer,UV sterilizer and etc.)

2. Bottle blowing system make PET plastic bottles ( Semi automatic / Fully automatic )

3. Air conveyor for empty bottle loading

4. Rinser-filler-capper 3 in 1 monoblock

5. Cap loader

6. Labeling machine ( PVC sleelve labeling machine /OPP hot melt glue labeling machine/Self-adhesive labeling machine )

7. Code printer (Ink-jet printer/ laser-jet printer)

8. Packaging ( PE shrink wrapping machine / Carton packing machine )

9. Palletizer

Hot Searches