- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1550*1946*1380mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Portable Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Raw material:

-

Stones Rocks Ores

-

Max feeding size(mm):

-

210

-

Discharge size(mm):

-

25-60

-

eccentric shatspeed(r/min):

-

330

-

Spare parts supply:

-

Anytime

-

Spare parts:

-

Jaw Plate Tooth Plate

-

Price:

-

Negotiatable

Quick Details

-

Application:

-

Mining Industry Stone Quarry Crushinng Plant

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Shunxiang

-

Dimension(L*W*H):

-

1550*1946*1380mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Portable Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Raw material:

-

Stones Rocks Ores

-

Max feeding size(mm):

-

210

-

Discharge size(mm):

-

25-60

-

eccentric shatspeed(r/min):

-

330

-

Spare parts supply:

-

Anytime

-

Spare parts:

-

Jaw Plate Tooth Plate

-

Price:

-

Negotiatable

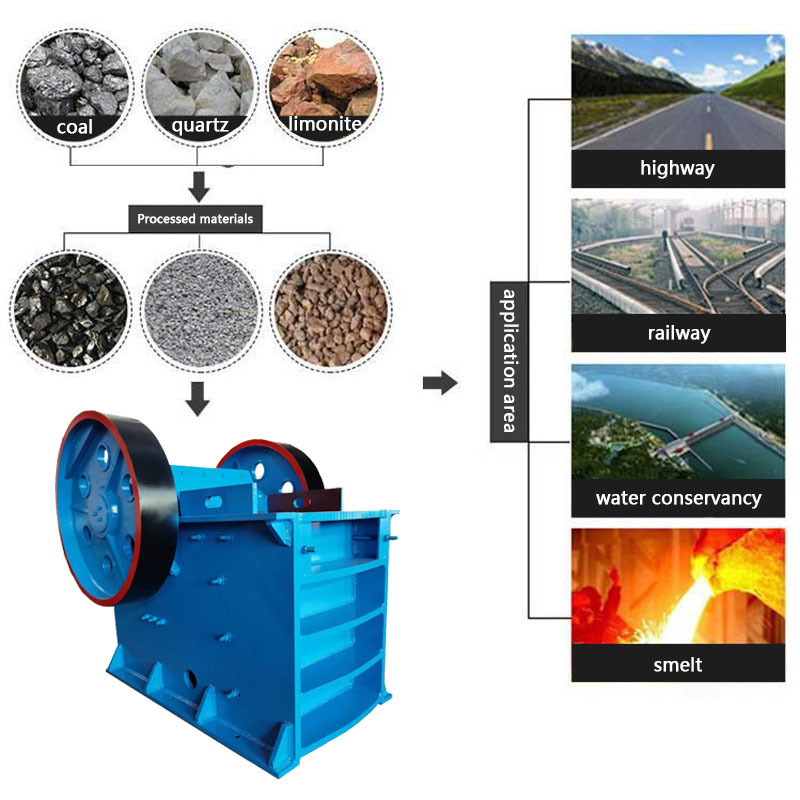

Product Description

This product is a customized product, which needs to be customized according to your needs, and the specific price is subject to the quotation of the sales staff

The jaw crusher is mainly composed of frame, eccentric shaft, big belt pulley, flywheel, side guard, elbow backseat,gapadjusting screw, reset spring, fixed jaw plate and movable jaw plate. Which

simulates the movement of two jaws of animals to complete material crushing operation.

Jaw crusher is the typical crusher among crusher, which can crush a variety of stone. It falls into two types: that produces coarse gravel and that produces sand.The former is used mainly to break big stones into smaller one, and the latter fine gravel.

Raw materials and applications :

Granite, Basalt, Quartz, Gold Ore, Copper Ore, Iron Ore, River Pebbles, Marble, concrete

blocked, etc.

Widely used in small mines, gravel yards, building construction sites, road construction and other major industries.

How to work

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

|

Model

|

Feed Inlet size(mm)

|

Inlet feeding

Length(mm)

|

Disharge port size(mm)

|

Handing Capacity

(t/h)

|

Eccentric shaft speed(r/min)

|

Moter Power

(kw)

|

Machine Weight

(kg)

|

Overall dimension(L*W*H)(mm)

|

|

PE150*250

|

150*250

|

125

|

10-40

|

1-3

|

250

|

5.5

|

800

|

720*660*850

|

|

PE200*300

|

200*300

|

180

|

15-50

|

2-6

|

260

|

7.5

|

1200

|

910*750*990

|

|

PE200*350

|

200*350

|

180

|

18-70

|

3-10

|

260

|

11

|

1500

|

1000*870*990

|

|

PE250*400

|

250*400

|

200

|

20-50

|

20-35

|

300

|

15

|

3000

|

1430*1310*1340

|

|

PE400*600

|

400*600

|

350

|

40-100

|

15-60

|

275

|

37

|

7000

|

1700*1732*1653

|

|

PE500*750

|

500*750

|

425

|

50-100

|

40-110

|

275

|

55

|

12000

|

2035*1921*2000

|

|

PE600*900

|

600*900

|

480

|

65-160

|

90-180

|

250

|

75

|

17000

|

2290*2206*2370

|

|

PE750*1060

|

750*1060

|

630

|

80-140

|

110-320

|

250

|

110

|

29000

|

2655*2302*3110

|

|

PE900*1200

|

900*1200

|

750

|

95-165

|

220-450

|

200

|

132

|

58000

|

3800*3166*3045

|

|

PE1000*1200

|

1000*1200

|

850

|

200-300

|

280-560

|

200

|

160

|

69000

|

5350*4280*3050

|

|

PE1200*1500

|

1200*1500

|

1020

|

150-300

|

400-800

|

180

|

220

|

100900

|

6380*5310*3710

|

|

PEX150*750

|

150*750

|

125

|

18-48

|

5-16

|

320

|

15

|

3800

|

1200*1500*1200

|

|

PEX250*750

|

250*750

|

210

|

25-60

|

15-30

|

330

|

22-30

|

5000

|

1667*1545*1020

|

|

PEX250*1000

|

250*1000

|

210

|

25-60

|

15-50

|

330

|

30-37

|

7000

|

1550*1946*1380

|

|

PEX250*1200

|

250*1200

|

210

|

25-60

|

20-60

|

330

|

37-45

|

8500

|

2192*1900*1950

|

|

PEX300*1300

|

300*1300

|

250

|

20-90

|

30-90

|

300

|

55-75

|

11500

|

1750*2320*1724

|

Product Advantages

Performance characteristics of jaw crusher:

1. Be and drive by diesel engine if the working site is limited 2. Deep crushing cavity, no dead zone, increasing capacity and output of the feeding 3. Large crushing ratio, uniform products particle size 4. Pad-style nesting population adjustment devices, and ease of adjustment range 5. Simple and reliable structure, low operation costs 6. The discharging size of jaw crusher can be adjusted to meet the requirements of different users 7. Low noise and less dust

1. Be and drive by diesel engine if the working site is limited 2. Deep crushing cavity, no dead zone, increasing capacity and output of the feeding 3. Large crushing ratio, uniform products particle size 4. Pad-style nesting population adjustment devices, and ease of adjustment range 5. Simple and reliable structure, low operation costs 6. The discharging size of jaw crusher can be adjusted to meet the requirements of different users 7. Low noise and less dust

Manganese steel dental plate

Manganese steel material, more wear-resistant, extends service life, convenient installation and disassembly

Flywheel

Effectively reducing vibration ensures smooth machine operation and improves work efficiency

Product Display

Wearing Parts

Main Products

Hot Searches