- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YINGYEE

-

Voltage:

-

as per your request

-

Dimension(L*W*H):

-

4.35*1.2*1.5

-

Weight:

-

4000 kg

-

Warranty:

-

12 months

-

Feeding width:

-

120mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

As for your respect

-

Control System:

-

Panasonic/Mitsubishi PLC

-

Product:

-

rolling shutter door slat machine cold machine forming supplier

-

After Warranty Service:

-

Video technical support

-

speed:

-

10m/min

-

Certification:

-

CE &ISO

-

Material:

-

GI Strips

-

Usage:

-

Shutter Door Slats

-

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YINGYEE

-

Voltage:

-

as per your request

-

Dimension(L*W*H):

-

4.35*1.2*1.5

-

Weight:

-

4000 kg

-

Warranty:

-

12 months

-

Feeding width:

-

120mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

As for your respect

-

Control System:

-

Panasonic/Mitsubishi PLC

-

Product:

-

rolling shutter door slat machine cold machine forming supplier

-

After Warranty Service:

-

Video technical support

-

speed:

-

10m/min

-

Certification:

-

CE &ISO

-

Material:

-

GI Strips

-

Usage:

-

Shutter Door Slats

-

Cutting type:

-

Hydraulic Cutting

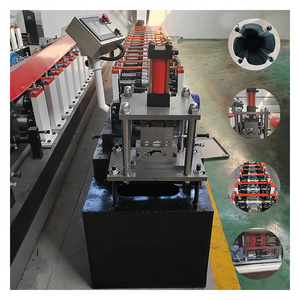

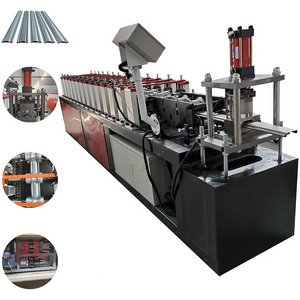

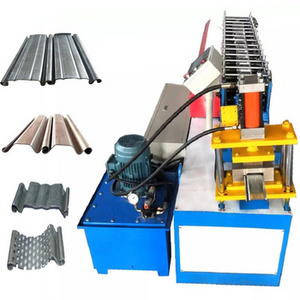

high quality steel shutter door roll forming machine for sale

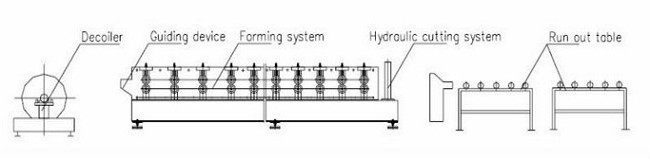

The shutter slat roll forming machine is fully automatic and it is easy to operate to form shutter slats. The shutter slat roll forming machine consists of one decoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system and control system.

Machine Configuration:

Decoiler, Feeding Applicator, Roll Forming Unit, Straightening Unit, Computer Control System, Hydraulic Cutting, Output Table

Working Flow:

Decoiler—Feeding Applicator—Roll Forming Unit—Computer Contol System—Hydraulic Cutting—Output Table

Technical parameters:

1. Matching material: GI Strips

2. Material thickness range: 0.3mm-0.8mm

3. Main motor power: 5.5kw

4. Forming speed: 10-15m/min

5. Hydraulic power: 3.0kw

6. Quantity of stands: about 16

7. Shaft Material and diameter: 70mm, material is 45# forge steel

8.Material Of the stations: A3 steel

9.Tolerance: 3m+/-1.0mm

10.Way Of Drive: 1.0 inch single chain driving

11. Controlling system: PLC system

12. Voltage: 380V/ 3phase/ 50 Hz

14.Size of the roll forming machine: about 4.35*1.2*1.5m

Pictures of machine:

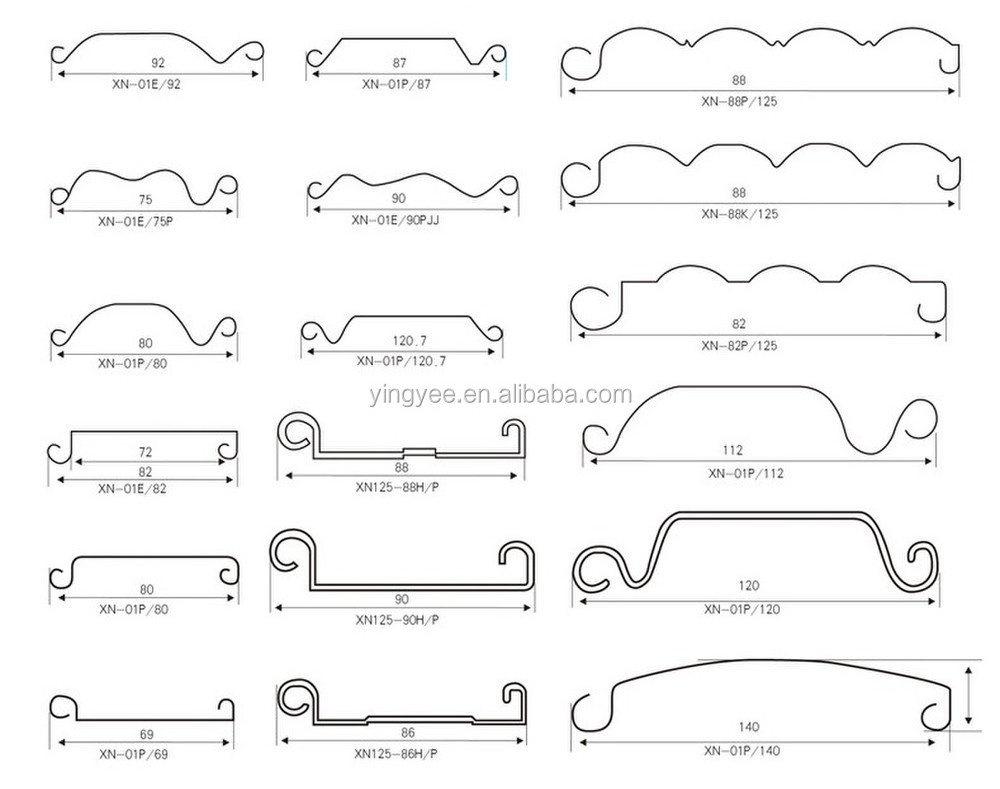

We can design kinds of roll forming machine according to your specific panel profile.

Main machine is nude, the computer box is packed by plastic film.