- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4500W

-

Dimension(L*W*H):

-

780*630*800MM

-

Weight (KG):

-

66 kg

-

Product name:

-

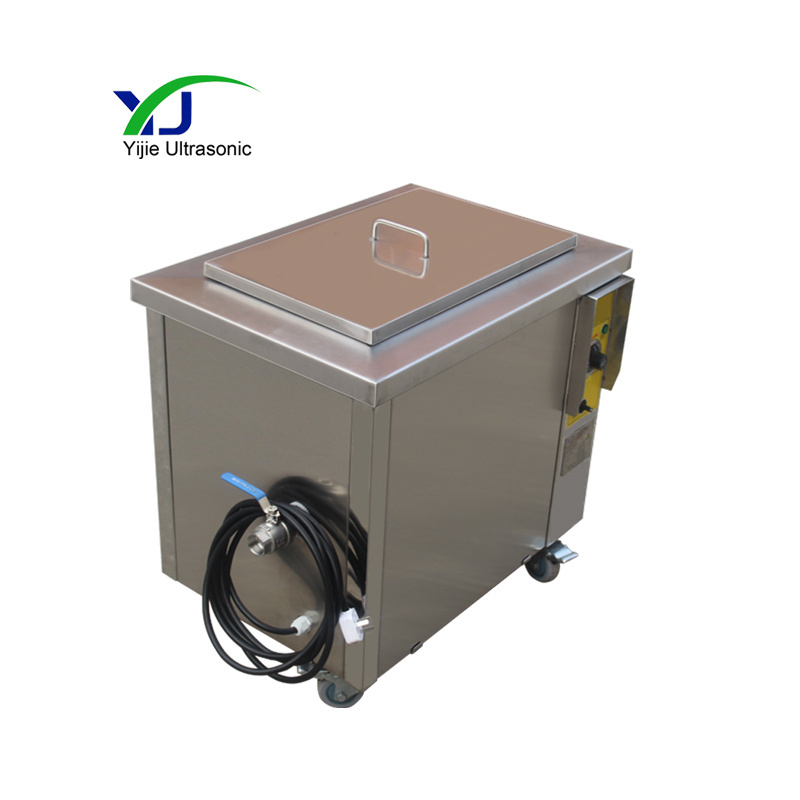

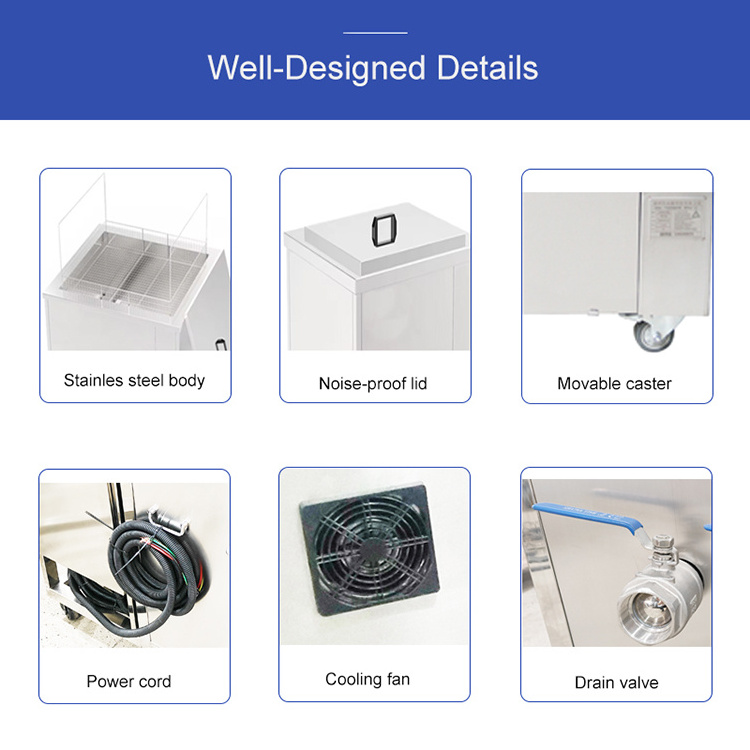

Easy Clean Industrial ultrasonic cleaner 108L

-

Function:

-

Ultrasonic cleaning

-

Features:

-

Reusable, Easy Operate

-

Service:

-

OEM, ODM, wholesale

-

Tank size:

-

600*450*400MM

-

Ultrasonic frequency:

-

40khz or 28khz or customize

-

Ultrasonic power:

-

1500W

-

Tank capacity:

-

108L

Quick Details

-

Core Components:

-

transducer, Generator

-

Place of Origin:

-

Guangdong,China

-

Brand Name:

-

Easy Clean

-

Power:

-

4500W

-

Dimension(L*W*H):

-

780*630*800MM

-

Weight (KG):

-

66 kg

-

Product name:

-

Easy Clean Industrial ultrasonic cleaner 108L

-

Function:

-

Ultrasonic cleaning

-

Features:

-

Reusable, Easy Operate

-

Service:

-

OEM, ODM, wholesale

-

Tank size:

-

600*450*400MM

-

Ultrasonic frequency:

-

40khz or 28khz or customize

-

Ultrasonic power:

-

1500W

-

Tank capacity:

-

108L

Products Description

|

Item

|

Value

|

|

Place of Origin

|

Guangdong, China

|

|

Use

|

Cleaning

|

|

Plug Type

|

US PLUG, UK Plug, AU Plug, EU Plug

|

|

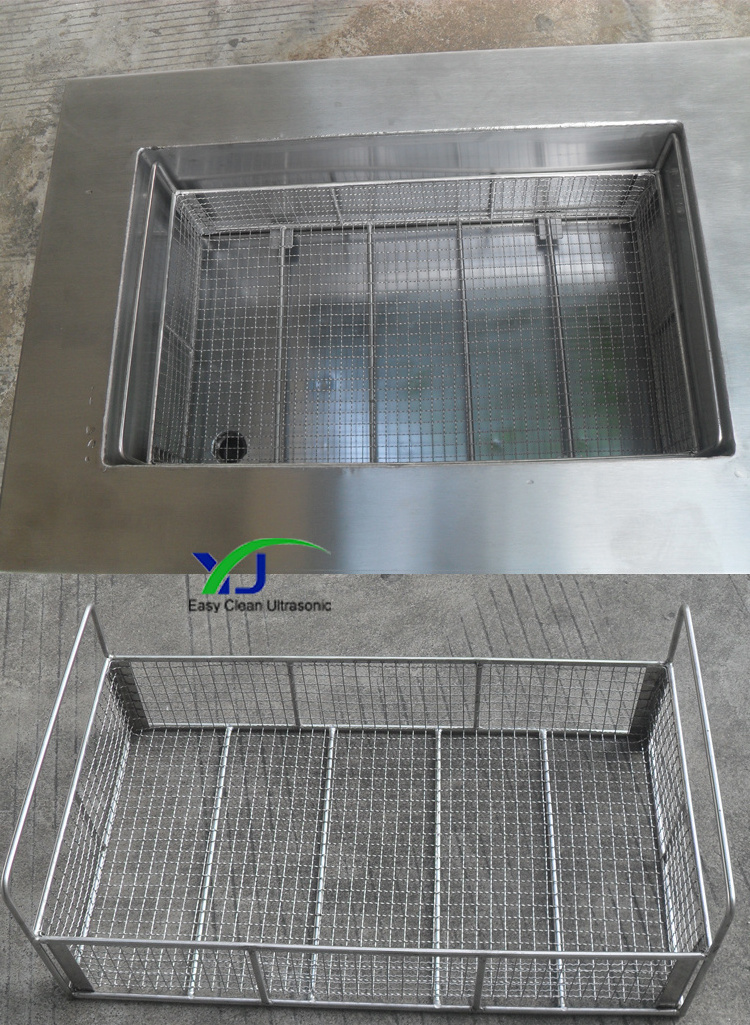

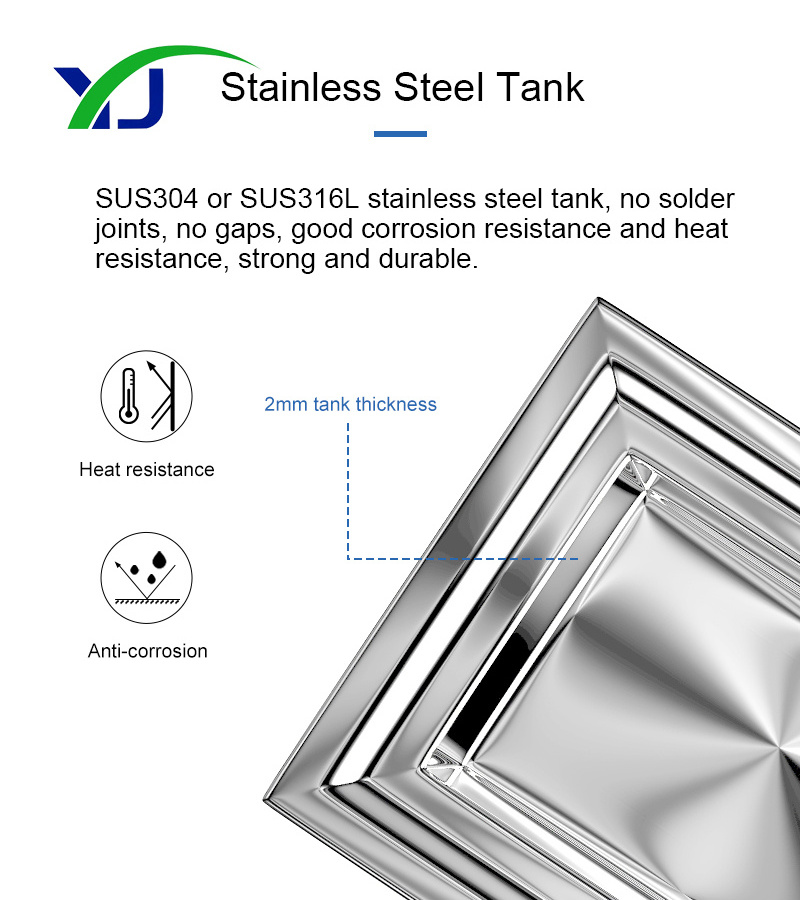

Tank Material

|

Stainless Steel SUS304/316, or customize

|

|

Service

|

OEM, ODM, wholesale

|

|

Ultrasonic Power

|

1500W

|

|

Transducer Quantity

|

30pcs

|

|

Ultrasonic Frequency

|

40KHZ or 28KHZ or customize

|

|

Tank Size

|

600*450*400MM

|

|

Tank Capacity

|

108L

|

|

Certificates

|

CE, ROHS,FCC

|

|

Warranty

|

1 year

|

You can also find below parameters with other capacity for this series:

|

Model

|

Capacity

|

Tank Size

|

Ultrasonic Power

|

Heating Power

|

Transducer Quantity

|

Time Control

|

|

JTS-1012

|

45L

|

500*300*300MM

|

600W

|

1500W

|

12pcs

|

1-99H

|

|

JTS-1018

|

61L

|

500*350*350MM

|

900W

|

1500W

|

18pcs

|

1-99H

|

|

JTS-1024

|

88L

|

550*400*400MM

|

1200W

|

3000W

|

24pcs

|

1-99H

|

|

JTS-1030

|

108L

|

600*450*400MM

|

1500W

|

3000W

|

30pcs

|

1-99H

|

|

JTS-1036

|

135L

|

600*500*450MM

|

1800W

|

4500W

|

36pcs

|

1-99H

|

|

JTS-1048

|

193L

|

700*550*500MM

|

2400W

|

6000W

|

48pcs

|

1-99H

|

|

JTS-1060

|

280L

|

800*600*600MM

|

3000W

|

6000W

|

60pcs

|

1-99H

|

|

JTS-1072

|

360L

|

1000*600*600MM

|

3600W

|

9000W

|

72pcs

|

1-99H

|

|

JTS-1090

|

560L

|

1000*800*700MM

|

4500W

|

18000W

|

90pcs

|

1-99H

|

|

JTS-1108

|

540L

|

1000*900*600MM

|

5400W

|

18000W

|

108pcs

|

1-99H

|

|

JTS-1144

|

960L

|

1200*1000*800MM

|

7200W

|

24000W

|

144pcs

|

1-99H

|

How Do Ultrasonic Cleaners Work?

Ultrasonic cleaners work by utilizing the process of cavitation, which is the formation and implosion of tiny bubbles in a liquid. Here's how it works:

1.Transducer: The ultrasonic cleaner contains a transducer, usually made of piezoelectric materials, which converts electrical energy into ultrasonic waves.

2.Liquid Bath: The object to be cleaned is placed in a liquid bath, typically water-based, but sometimes with added cleaning agents to enhance the process.

3.Ultrasonic Waves: When the transducer is activated, it emits high-frequency sound waves (ultrasonic waves) into the liquid. These waves travel through the liquid and create alternating high-pressure and low-pressure cycles.

4.Cavitation: During the low-pressure phase of the ultrasonic wave, microscopic bubbles form in the liquid at points where the pressure drops low enough to allow vaporization. These bubbles are filled with a mixture of vapor and gas from the liquid.

5.Bubble Implosion: As the pressure cycles back to high-pressure, the bubbles rapidly collapse or implode due to the high-pressure environment. This implosion generates intense localized energy, releasing shockwaves and creating microjets of liquid that impact the surface of the object.

6.Cleaning Action: The impact and energy released during bubble implosion dislodge dirt, grease, and other contaminants from the surface of the object. This process reaches into tiny crevices and hard-to-reach areas, providing thorough cleaning.

7.Rinsing: After cleaning, the object is usually rinsed with clean water to remove any remaining cleaning solution or loosened contaminants.

8.Drying (Optional): Depending on the application, the object may be dried using methods such as air drying, wiping, or heated drying.

Overall, ultrasonic cleaners offer a highly effective and efficient method for cleaning a wide range of objects, from delicate jewelry to complex mechanical parts, by harnessing the power of cavitation.

Hot Searches