- Product Details

- {{item.text}}

Quick Details

-

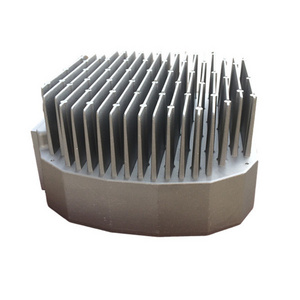

Name:

-

Die Casting Parts

-

Shape:

-

Irregular

-

Type:

-

Die Casting

-

Condition:

-

New

-

Standard:

-

ISO9001 Certified QMS

-

Color:

-

Colorful

-

Dimensions:

-

Customized Sizes

-

Material:

-

Aluminum

-

Certification:

-

ISO 9001:2015

-

MOQ:

-

Negotiable

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SPT

-

Model Number:

-

high pressure die cast

-

Name:

-

Die Casting Parts

-

Shape:

-

Irregular

-

Type:

-

Die Casting

-

Condition:

-

New

-

Standard:

-

ISO9001 Certified QMS

-

Color:

-

Colorful

-

Dimensions:

-

Customized Sizes

-

Material:

-

Aluminum

-

Certification:

-

ISO 9001:2015

-

MOQ:

-

Negotiable

SPECIFICATION

|

Manufacturing Method

|

Die Casting Services

|

|

Material Standard

|

GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 Aluminum alloy:

ADC12, ADC10, A360, A380, A356, 6061, 6063 2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 Magnesium alloy: AZ91D, AM60B, 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 Zinc alloy: ZA3#,ZA5#,ZA8# |

|

Tolerance

|

±0.02mm

|

|

General Casting Tolerance

|

CT4-CT7 ISO 8062 / Customized

|

|

Design Software

|

UG, Pro-E, Inventor

|

|

Mould Manufacturing

|

Yes

|

|

Casting Stimulation

|

Yes

|

|

Quality Standard

|

ISO 9001

|

|

Ultimate machining tolerance

|

0.005mm

|

|

Machining Roughness

|

Ra0.8-Ra3.2 according to customer requirement

|

|

Heat Treatment

|

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

|

Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat

coating, Finish Painting |

|

Processing

|

1, Sign Drawing (General clients provide the drawing or samples)

2, Opening the Mold 3, Die Casting ( Aluminium or Aluminium Alloy) 4, Precision Machining (Burring, Lathe, Milling, etc) 5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing 6, Inspection and Packing |

|

Equipment of Casting

|

1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T

2. Gravity casting machine: 5 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines5. Investment casting machine:2 productioni lines 6. Machining: 5Sets CNC Machines;3 sets Milling machines; 3 setsTurning machines; 10 sets drill and tap machines |

|

Testing Facility

|

Spectrometer, tensile test machine, hardness test machine,CMM dimension report

|

|

Service

|

Sand casting, investment casting, die casting, CNC Machining casting, fabrication

|

Hardness Tester

Impact Test

Run Out Gaging

Universal Tensile Testing Machine

Spectrometer

UT

Statement

In order to protect the intellectual property rights of customers, the products we display are all approved by customers. Except that some products are independently developed by our company, we will not sell products developed by customers themselves. Please provide me drawings for customization.

PATENTED MATERIAL

After 3 years of research and development, the new material innovated by our company and Australian agricultural doctor was put into the market in 2013. This new material is divided into three series, which are Abrasinite 600,Abrasinite 500,Toughnite 400. It has the advantages of low carbon, high performance (hard and wear-resistant), green and low price, and has been widely used in agriculture, transportation, mining and so on.

Abrasinite 600

Ideal replacement for Ni-Mo modified Cr27 cast iron

Hardness HB620-660

Charpy unnotched Impact Value: >10 J

Price of casting: At least 30% saving of Ni-Mo modified Cr27

Abrasinite 600 has very good wear resistance with lower cost as it uses only about 1.5% of Cr, no Ni, Mo, no other expensive alloy element added. The price of this material can be quite competitive.

Abrasinite 500

Hardness HB530-560

V-notched Charpy Impact Value: >19J

If the hardness requirement is not very high, and the need for impact resistance is high, Abrasinite 500 is a good choice.

Toughnite 400

Tensile Strength >1000MPa

Yield Strength ~800Mpa

Hardness HB400-420

V-notched Charpy Impact Value: 30J

This low cost casting steel does not need quenching to get high strength,

can avoid deformation from quenching.

We've done experiments in various fields, and here's the field of agriculture.

Abrasinite 500 with patented much finer particle powder welding VS. 8630 with normal big particle welding at the same soil and enduring the same hours.

8630 Body

8630 with Tungsten Tiles after 360 acres, the body material is nearly all gone.

Abrasinite 500 Body

Abrasinite 500 with same Tungsten Tiles after 6500 acres still perform perfectly.

Q1. Are you a factory or trade company?

A: We are a factory with over 20 years in casting(investment casting, die casting, sand casting), forging, fabrication and machining. We service customers in various fields such as mining, agriculture, car parts ,etc.

Q2. Where is your factory?

A: Our factory locates in Dandong City, Liaoning Province, where close to Dalian port within 1 hr drive.

Q3. How to quote?

A: Received the sample or drawing, then we will make the quotation.

Q4. How about the MOQ?

A: Depend on the weight and material, if it is our daily melting material, there is no MOQ.

Q5. Payment terms

A: Mold costs: 50% deposit, balance after sample approval.

Mass production: 50% deposit, balance upon B/L available.

Q6.Delivery time

A: Normally 25-45 days;Standard or customized will both be available.

Q7. How about the packing?

A: Standard or customized will both be available.We will consider the transfer at warehouse and long time anti rust during on the sea.

Q8. How can I get more information?

A:If you need more information, you can send email to jennyj@sharpentech.cn, if you need any instant answer, please call 0086-155-6615-8182.

A: We are a factory with over 20 years in casting(investment casting, die casting, sand casting), forging, fabrication and machining. We service customers in various fields such as mining, agriculture, car parts ,etc.

Q2. Where is your factory?

A: Our factory locates in Dandong City, Liaoning Province, where close to Dalian port within 1 hr drive.

Q3. How to quote?

A: Received the sample or drawing, then we will make the quotation.

Q4. How about the MOQ?

A: Depend on the weight and material, if it is our daily melting material, there is no MOQ.

Q5. Payment terms

A: Mold costs: 50% deposit, balance after sample approval.

Mass production: 50% deposit, balance upon B/L available.

Q6.Delivery time

A: Normally 25-45 days;Standard or customized will both be available.

Q7. How about the packing?

A: Standard or customized will both be available.We will consider the transfer at warehouse and long time anti rust during on the sea.

Q8. How can I get more information?

A:If you need more information, you can send email to jennyj@sharpentech.cn, if you need any instant answer, please call 0086-155-6615-8182.

Hot Searches