- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand name:

-

Dongya

-

Tool Diamensions:

-

243x58x246mm (9.56x2.28x9.68 in.)

-

Net Tool Weight:

-

1.48kgs (3.25lbs)

-

Operate Pressure:

-

4~7Kg/cm (60~100Psi)

-

Load Capacity:

-

100 Staples

-

Package:

-

Color Box Packing

-

Quality:

-

Industrial Quality

-

Material:

-

Aluminum Alloy

-

Application:

-

Decking

Quick Details

-

No-Load Speed:

-

/

-

Model Number:

-

9040-CL105

-

Warranty:

-

/

-

Place of Origin:

-

Zhejiang, China

-

Brand name:

-

Dongya

-

Tool Diamensions:

-

243x58x246mm (9.56x2.28x9.68 in.)

-

Net Tool Weight:

-

1.48kgs (3.25lbs)

-

Operate Pressure:

-

4~7Kg/cm (60~100Psi)

-

Load Capacity:

-

100 Staples

-

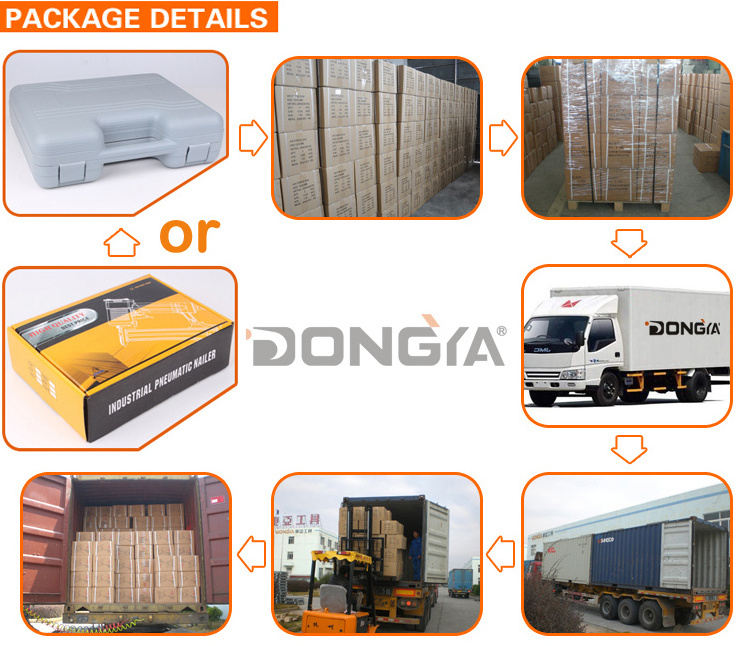

Package:

-

Color Box Packing

-

Quality:

-

Industrial Quality

-

Material:

-

Aluminum Alloy

-

Application:

-

Decking

40 Years Production Experience

Industry's Leading Factory

Engineer With 30 Years Experiences In Nail Gun Industry

Imported Spare Parts

|

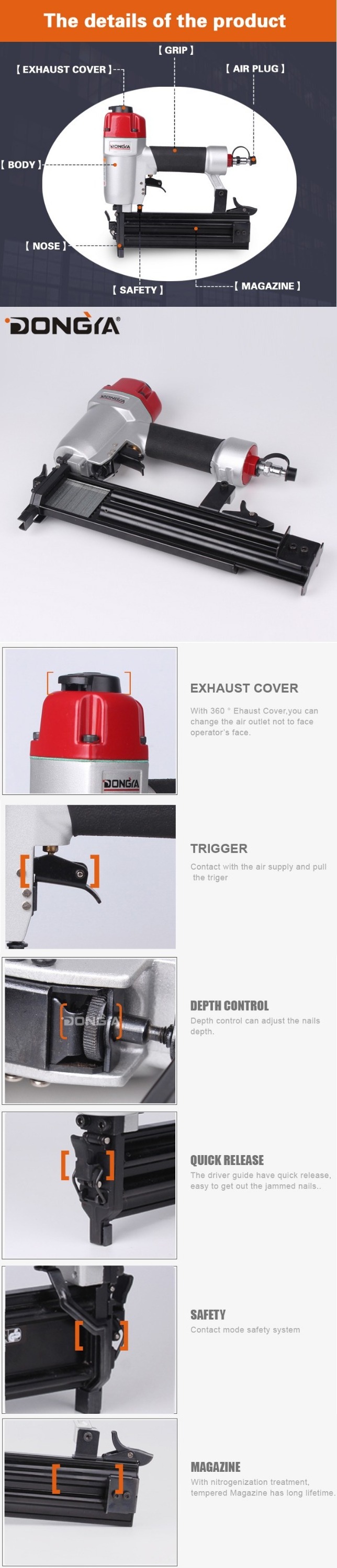

FEATURE • "Contact mode" safety system • Light die cast body of aluminum alloy • Bottom loading design • Remain nails display available • Non-marring tip available |

|

Parameters

| Tool Diamensions: | 243x58x246mm (9.56x2.28x9.68 in.) |

| Net Tool Weight: | 1.48kgs (3.25lbs) |

| Operate Pressure: | 4.0~7.0Kg/cm (60~100Psi) |

| Load Capacity: | 100 Staples |

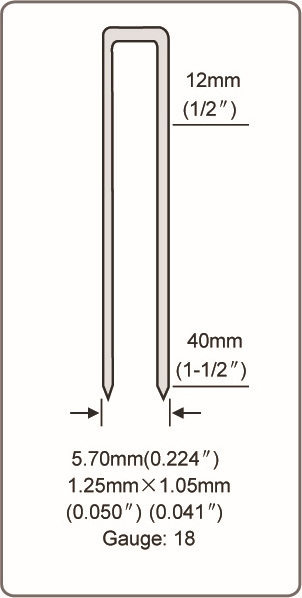

| Staple Crown: | 5.70mm(0.224 " ) |

| Staple Length : | 12~40mm(1/2 " ~1-1/2 " ) |

| Staple Thickness : | 18 Gauge 1.25x1.05mm (0.050 ” x 0.041”) |

Advantage

1. 300000 working times

2. CE and ISO9001 international certificate

3. Easily broken parts are imported

4. 100% Spare parts can be supplied to you.

5. Very powerful for hard wood

MAIN APPLICATION

SERVICE AND REPAIRS

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can't return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||