- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

GLE Series

-

Voltage:

-

customerized

-

Dimension(L*W*H):

-

customerized

-

Power (kW):

-

45

-

Weight:

-

15000 KG

-

Name:

-

Plastic sheet Extrusion Line

-

Raw material:

-

Pvc pet PLA Powder

-

Usage:

-

Plastic Extrusion

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

34:1

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

GLE Series

-

Voltage:

-

customerized

-

Dimension(L*W*H):

-

customerized

-

Power (kW):

-

45

-

Weight:

-

15000 KG

-

Name:

-

Plastic sheet Extrusion Line

-

Raw material:

-

Pvc pet PLA Powder

-

Usage:

-

Plastic Extrusion

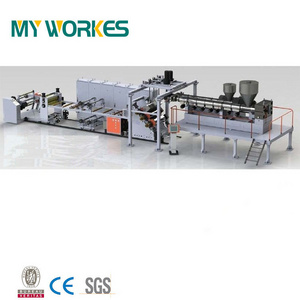

Product images

Product Description

APPLICATION

The sheet extruder is composed of extrusion, calendaring, traction and rolling.

The main parts are abrasion resistant, resistant to corrosion, high-temperature

resistant by high quality specially-treated.

Low resistanceforce in die head extruding channel makes sheet thickness evenly,

the internal spiral tank in three rollers ensures an effective cooling and it is easy to

change and install net changer with the hydraulic pressure unit, no need to stop machine.

The machine extrudes PP/PS granule to PP/PS sheet with single color, which is used for producing

plastic products by plastic thermoforming

machines, like cups, food container, trays, dishes, bowls, lids, etc.

Feature of equipment

The main parts, such as screw, barrel, screen exchanger, T-die adopt superior alloy steel (38 CrMoAIA) with high hardness, strong corrosions resistance and long operating life after nitrogen treatment.

The screw adopts big L/D (length/diameter) Ratio, equal plasticization and high plasticizing capability.

Non-stop fast screen changer with double-sieve, controlled by hydraulic device, the operation is convenient and improve the production efficiency.

The calendar, haul off unit and winder adopt integration design, fine appearance, convenient and fast installation and adjustment.

The machine frame adopt square steel, to make sure the machine works stably in high speed. The motor is connected with gear box directly, improve production efficiency and lower energy consumption

Product Paramenters

Parameter s of GLSJ series double stage extrusion granulation unit

|

Model/ Type |

D(mm) |

L/D |

n(r/min) |

P(kw) |

Q(kg/h) |

|

GLSJ-52/100 |

50.5 |

28-40 : 1 |

500 |

45 |

150-250 |

|

100 |

7-12 : 1 |

85 |

37 |

||

|

GLSJ-65/150 |

62.4 |

28-40 : 1 |

500 |

55-75 |

500-700 |

|

150 |

7-12 : 1 |

85 |

45-55 |

||

|

GLSJ-75/180 |

71 |

28-40 : 1 |

500 |

90-110 |

750-900 |

|

180 |

7-12 : 1 |

85 |

55-75 |

||

|

GLSJ-95/200 |

92 |

28-40 : 1 |

400-500 |

250-315 |

1000-1200 |

|

200 |

7-12 : 1 |

85 |

75-90 |

Co- rotating twin screw extruder system