- Product Details

- {{item.text}}

Quick Details

-

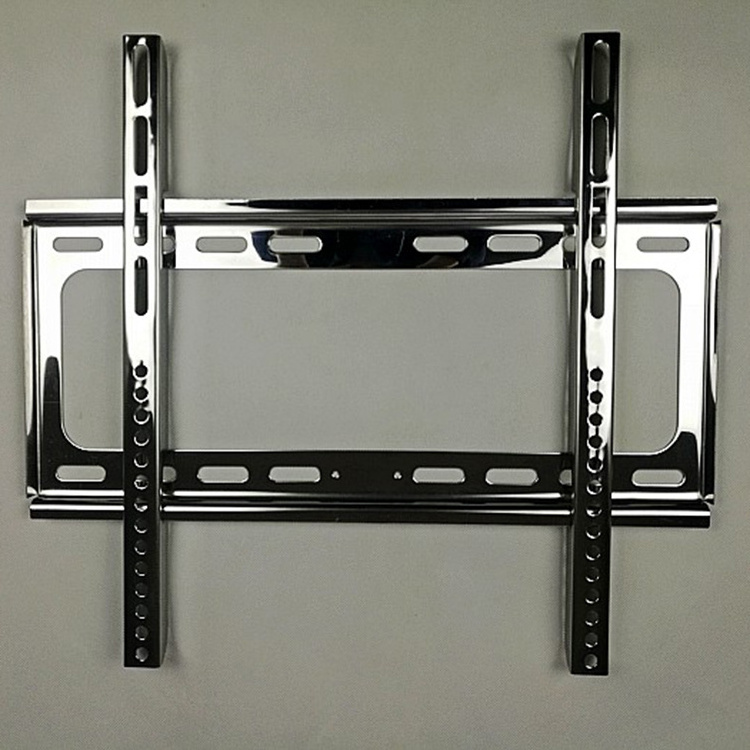

Support material:

-

Aluminum alloy, steel,Etc.

-

Support size:

-

22cm,*26cm, 47cm*43cm, etc,customizable

-

Support color:

-

Raw material color or black, white, etc

-

Support characteristics1:

-

High bearing capacity

-

Support characteristics2:

-

Strong stability

-

Support characteristics3:

-

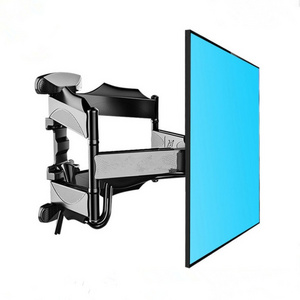

Adjust the Angle, multiple perspectives

-

Support characteristics4:

-

Flexible and changeable

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Huicong Hardware

-

Model Number:

-

HCT-109

-

Support material:

-

Aluminum alloy, steel,Etc.

-

Support size:

-

22cm,*26cm, 47cm*43cm, etc,customizable

-

Support color:

-

Raw material color or black, white, etc

-

Support characteristics1:

-

High bearing capacity

-

Support characteristics2:

-

Strong stability

-

Support characteristics3:

-

Adjust the Angle, multiple perspectives

-

Support characteristics4:

-

Flexible and changeable

Production process of TV bracket

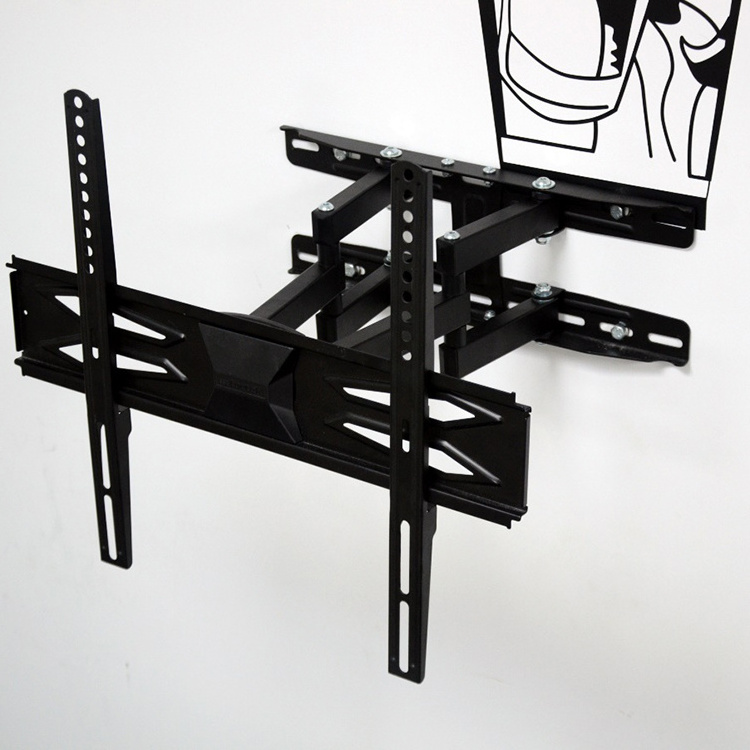

First of all, the production process of the TV stand starts from the material preparation. Production plants need to purchase suitable metal materials, such as steel plates aluminum, etc., and other accessories. These materials need to be selected in strict accordance with specifications to ensure product quality.

After material preparation, the next step is manufacturing. The production plant will cut the steel plate according to the design requirements, and then use the punching machine, bending machine and other equipment to form the metal sheet. These devices enable sheet metal to complete various bending, cutting and hole processing processes with high precision and efficiency.

After the manufacturing process is completed, the next step is the welding process. Workers will weld each component according to the design drawings and requirements to ensure that the structure of the bracket is solid and reliable. Skilled welders need to master welding technology and welding materials, and carry out welding quality detection and control. After welding is

completed, the support will enter the spraying process. First of all, it is necessary to polish and remove rust on the surface of the bracket to eliminate impurities. Then, the use of electroplating, spraying and other processes for anti-corrosion, anti-rust treatment of the bracket, while coloring the bracket to improve the appearance of the product quality.

Next, assembly and packaging. In the assembly link, workers will be welded and sprayed to complete the various parts of the combination, while debugging and testing according to product requirements, to ensure that

The rack can be used normally. In the packaging process, the factory will paste protective film on the surface of the bracket, and use special packaging materials to package the bracket to avoid damage during transportation.

Custom Products

Why Choose Us

Hot Searches