- Product Details

- {{item.text}}

Quick Details

-

Temperature range:

-

Room temperature ~ 1550 ° C

-

Heating rate:

-

1~80°C/min

-

Cooling time:

-

15min (1000°C--100°C)

-

Balance measurement range:

-

1mg ~ 2g, can be extended to 30g

-

Sensitivity:

-

0.01mg

-

Constant temperature time:

-

0~300min Arbitrary setting

-

Power supply:

-

AC220V 50Hz

-

Certification:

-

GS

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BAXIT

-

Product name:

-

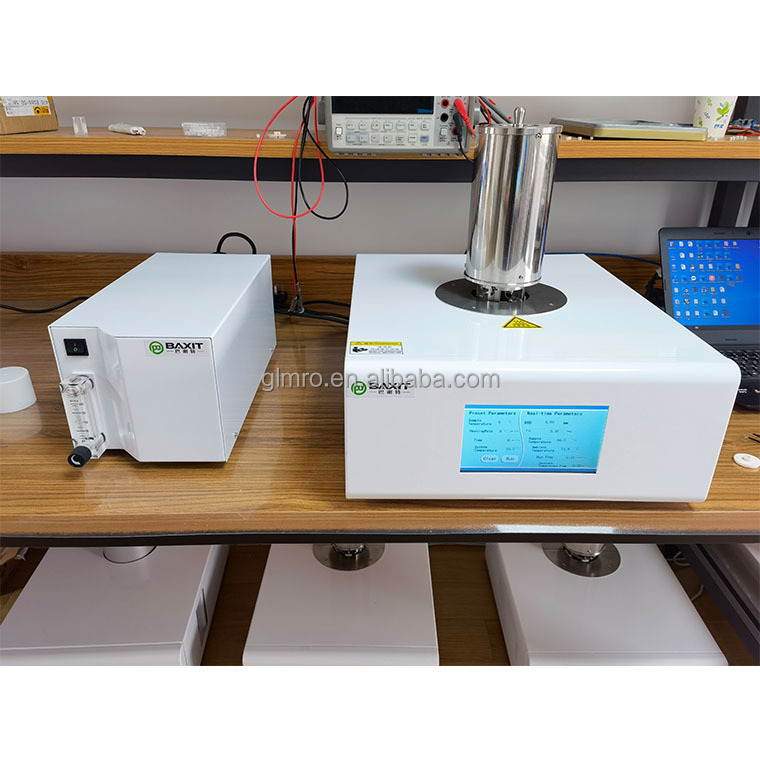

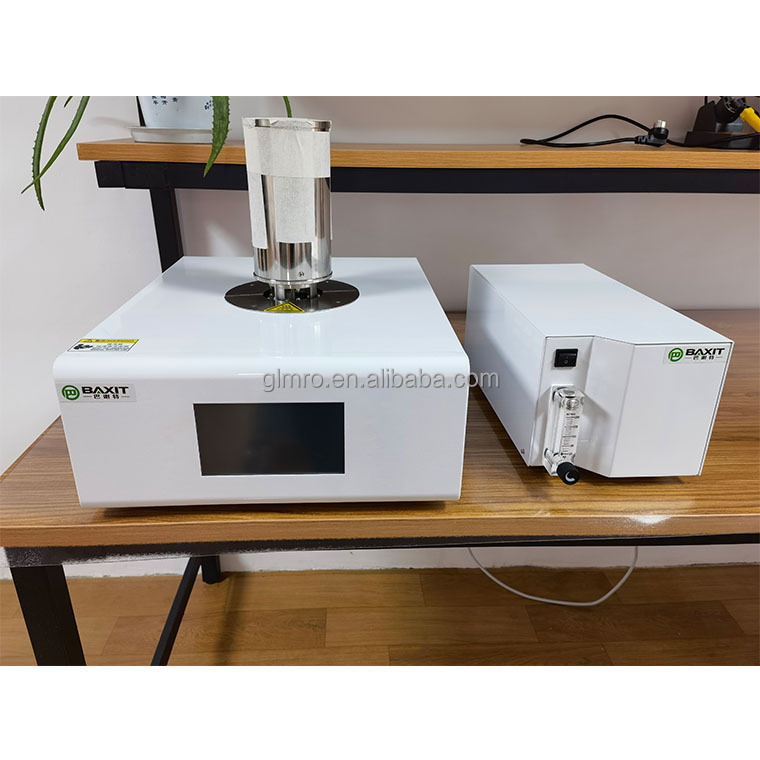

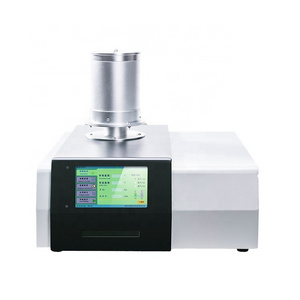

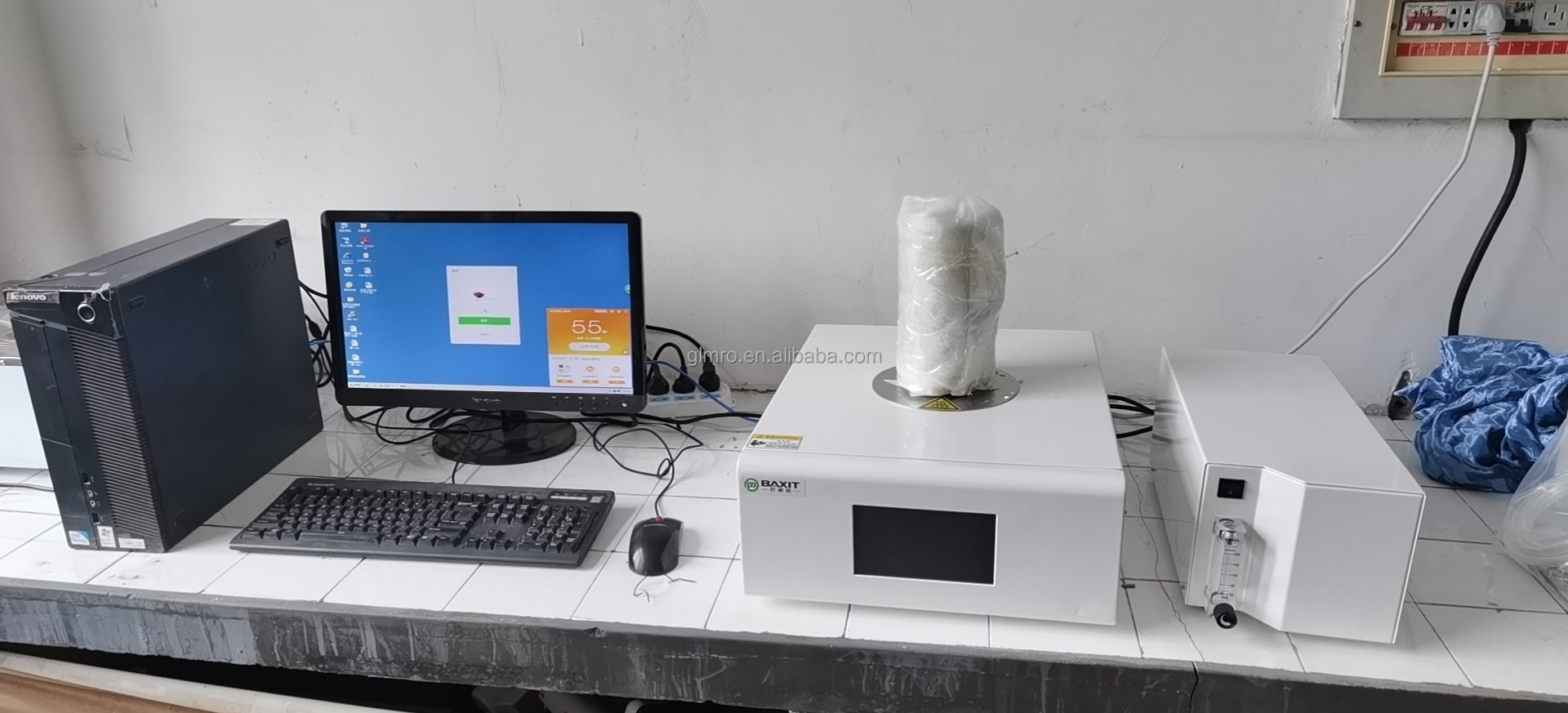

TGA 1550C Thermogravimetry Analyzer Thermal Stability Test

-

Temperature range:

-

Room temperature ~ 1550 ° C

-

Heating rate:

-

1~80°C/min

-

Cooling time:

-

15min (1000°C--100°C)

-

Balance measurement range:

-

1mg ~ 2g, can be extended to 30g

-

Sensitivity:

-

0.01mg

-

Constant temperature time:

-

0~300min Arbitrary setting

-

Power supply:

-

AC220V 50Hz

-

Certification:

-

GS

High Quality 1550C TGA Thermogravimetry Analyzer Quantitative Analysis Of Ingredients Thermal Stability Test

Product introduction:

Thermogravimetric analysis (TG, TGA) is the change of the mass of a sample with temperature or time during temperature rise,constant temperature or temperature reduction. The purpose is to study the thermal stability and composition of the material. It is widely used in research and development, process optimization and quality monitoring in various fields such as plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials.

Controller and software advantages:

Ⅰ . Imported 32bit ARM processor Cortex-M3 core, sampling speed, processing speed is faster.

Ⅱ . 24bit four-way sampling AD collects DSC signals and TG signals and temperature T signals.

Ⅲ . The power supply and water circulation part is separately controlled by 8bit single-chip microcomputer, so that the main unit and the cooling part are separated, and they do not interfere with each other, but the two are closely connected, and the cooling

part is controlled by the host.

Ⅰ . Imported 32bit ARM processor Cortex-M3 core, sampling speed, processing speed is faster.

Ⅱ . 24bit four-way sampling AD collects DSC signals and TG signals and temperature T signals.

Ⅲ . The power supply and water circulation part is separately controlled by 8bit single-chip microcomputer, so that the main unit and the cooling part are separated, and they do not interfere with each other, but the two are closely connected, and the cooling

part is controlled by the host.

Spectrum analysis:

The following characteristics of the measurement and study materials:

DSC: melting, crystallization, phase change, reaction temperature and reaction heat, heat of combustion, specific heat.

TGA: thermal stability, decomposition, oxidation and reduction, adsorption desorption, free water and crystal water content,composition ratio calculation.

DSC: melting, crystallization, phase change, reaction temperature and reaction heat, heat of combustion, specific heat.

TGA: thermal stability, decomposition, oxidation and reduction, adsorption desorption, free water and crystal water content,composition ratio calculation.

TGA Results:

∙ Thermal stability

∙ Compositional analysis

∙ Mass changes

∙ Decomposition behavior

∙ Pyrolysis

∙ Water amount

∙ Identification of solvents

∙ Compositional analysis

∙ Mass changes

∙ Decomposition behavior

∙ Pyrolysis

∙ Water amount

∙ Identification of solvents

Thermogravimetric analysis

, or TGA (also known as thermogravimetry, or TG) measures the mass change of a substance while the sample is subjected to a controlledtemperature program.

“Top-loading arrangement” simply means that the sample is located above the balance. This ensures safe and easy handling.

“Top-loading arrangement” simply means that the sample is located above the balance. This ensures safe and easy handling.

The Complementary Methods DSC and TGA

:

The strength of DSC lies in its capability of detecting and monitoring a material’s phase transitions.

However, the reason for a DSC effect is not always obvious; it might be:

∙ a polymorphic transition,

∙ a melting effect, or

∙ an effect caused by a mass loss.

Therefore, DSC and TGA are very often used as complementary techniques. By applying the methods in combination, it is possible to distinguish whether an effect is related to structural changes and to determine in which temperature ranges mass changes occur. This information facilitates interpretation of the effects detected – especially when a sample’s composition is unknown.

∙ a polymorphic transition,

∙ a melting effect, or

∙ an effect caused by a mass loss.

Therefore, DSC and TGA are very often used as complementary techniques. By applying the methods in combination, it is possible to distinguish whether an effect is related to structural changes and to determine in which temperature ranges mass changes occur. This information facilitates interpretation of the effects detected – especially when a sample’s composition is unknown.

Parameter setting of oxidation induction period experiment

Parameter setting of melting point and phase transition temperature

SIMULATIVE

OPTIMIZATION

OF DEBINDING

OPTIMIZATION

OF DEBINDING

Figure 1:

Experimental TGA data (symbol) agree well with simulation results (solid line) at heating rates of 0.1, 0.3, 1, 5 and 10 K/min.

Melting point, enthalpy and phase transition temperature analysis flow: left strike turns green-analysis-peak comprehensive analysis;

Oxidation induction analysis process:

left strike turns green-analysis-oxidation induction period;

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Features:

1 . Furnace heating using nickel-cadmium alloy double-wound wire system to reduce interference, but also high temperature.

2 . Tray sensor, using precious metal nickel-cadmium alloy Seiko build, with high temperature, anti-oxidation, corrosion resistance

and so on.

3 . Power supply, circulation and cooling part of the host separate to reduce the heat and vibration on the microbalance impact.

4 . Using open cover structure, easy to operate. Move the furnace body to put the sample operation is very difficult, easy to cause

the sample rod damage.

5 . The host uses water thermostat to isolate the thermal effect of the heating furnace on the chassis and the microbolometer.

6 . According to customer requirements to replace the furnace.

1 . Furnace heating using nickel-cadmium alloy double-wound wire system to reduce interference, but also high temperature.

2 . Tray sensor, using precious metal nickel-cadmium alloy Seiko build, with high temperature, anti-oxidation, corrosion resistance

and so on.

3 . Power supply, circulation and cooling part of the host separate to reduce the heat and vibration on the microbalance impact.

4 . Using open cover structure, easy to operate. Move the furnace body to put the sample operation is very difficult, easy to cause

the sample rod damage.

5 . The host uses water thermostat to isolate the thermal effect of the heating furnace on the chassis and the microbolometer.

6 . According to customer requirements to replace the furnace.

Main technical parameters of the instrument:

|

TGA model

|

BXT-TGA-1250 / BXT-TGA-

1550

|

|

Temperature range

|

room temperature ~

1250

℃/room temperature ~

1550

℃

|

|

Temperature resolution

|

0.1 ℃

|

|

Temperature fluctuation

|

± 0.1 ℃

|

|

Heating rate

|

1 ~ 80 ℃ / min

|

|

Temperature control

|

heating, constant temperature, cooling

|

|

Constant temperature

|

0 ~ 300min arbitrarily set

|

|

Cooling time

|

15min (1000 ℃ ~ 100 ℃)

|

|

Balance measurement range

|

1mg ~ 2g can be extended to 5g

|

|

Sensitivity

|

0.01mW

|

|

Constant temperature

|

0 ~ 300min arbitrarily set

|

|

Display

|

24bit color, 7 inch LCD touch screen display

|

|

Data interface

|

standard USB interface

|

|

Power

|

AC220V 50Hz (AC110V,60Hz)

|

MAIN CONFIGURATIONS

|

Host

|

1 set

|

|

U disk

|

1 sheet

|

|

data wire; data cable

|

2 pieces

|

|

Power cord

|

1 root

|

|

Aluminum crucible

|

200 animals

|

|

Metal cover

|

2.

|

|

Raw tape

|

1 volume

|

|

Pure tin grain

|

1 bag

|

|

10A fuse

|

2 animals

|

|

Sample spoon/pressure bar/tweezers

|

1 each

|

|

aurilave

|

one

|

|

Trachea

|

2 pieces

|

|

Instructions

|

1 copy

|

|

Warranty

|

1 copy

|

|

certificate

|

1 copy

|

Company introduction:

Shanghai Glomro Industrial Co., Ltd. is a professional Laboratory equipment supplier which located in Shanghai who dedicated in testing equipment field for more than 1 0 years. G L O means Global, M R O means Maintenance, Repair & Operations.Glomro means Global M R O solutions.

We can provide laboratory instruments such as D S C Differential Scanning Calorimeter, T G A Thermogravimetric Analyzer, Oxygen Bomb Calorimeter thermal conductivity meter, vibration tester, environmental testing chamber, tensile machine we, Industrial Portable Air Conditioner. can also provide solutions for you to build high tech and high quality laboratory. In order to provide more suitable equipment for our customers and increase the competency of products. We have established our own designer team to develop the most high tech solutions each year, thousands of solutions for your choice to help you catch the market. Over the past few years of production and management and exploration, we set up our own quality management system. Glomro always implement the concept of customer value creation for customers tailored products to meet the needs of different customers, and continuously provide customers with solutions to technical problems, further exploration innovation, and excellence. We can provide customers with professional and prompt pre-sales, mid-sales, and after-sales support.

Warmly welcome you and opening up the boundaries of communication. We synchronize with your ideal partner.

FAQ

Q:Are your company a trading one or a factory?

A:Factory + trade (integration),More than 10 years focusing on test instruments field,6 years exporting experience.

Q:After an order is placed, when to deliver?

A:Generally about 10-25days, If we have inventory, we can arrange shipment within 3 days. Please be aware that our production lead

times depend on specific items and item quantities.

Q:What about the warranty with after - sales services?

A:The testing machine is guaranteed for 12 months by Shanghai Glomro Building Industrial Co.Ltd ,One year promise including free

maintenance and changing Instrument components.Besides, Full-life cycle technical support is provided.

Q:What about the product' services and quality?

A:Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. each of our product

provide video training to show you how to install & operate. We can arrange engineer to train the operation of equipment to

customer’s company when you need.

FOR MORE INFOMATION,CLICK SEND NOW

Hot Searches