- Product Details

- {{item.text}}

Quick Details

-

Core Components::

-

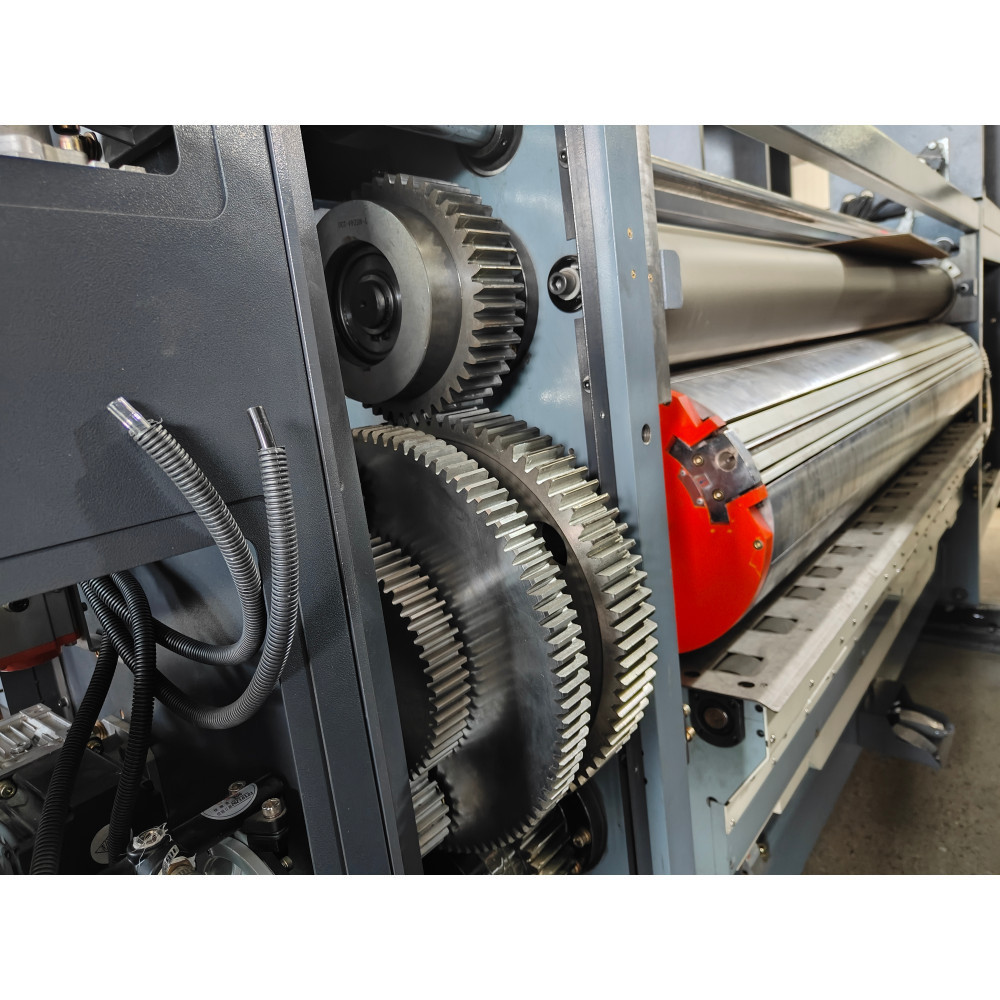

Gearbox, Pressure vessel, Pump, Gear, Bearing

-

Key Selling Points::

-

Automatic

-

Product name:

-

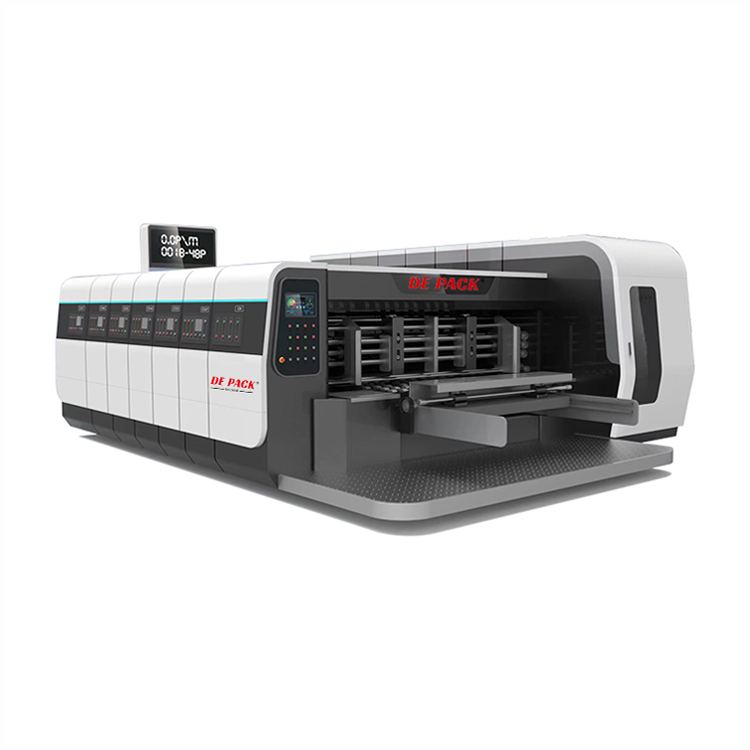

High Speed Flexo Printing Slotting Die Cutting Machine

-

Printing colors::

-

1-6 Colors

-

Function::

-

Corrugated Carton Printing Slotting Diecutting

-

Place of origin::

-

Dongguang Cangzhou Hebei China

-

Finished Products::

-

Corrugated Paper Board Carton Boxes

Quick Details

-

Brand Name:

-

DE PACK

-

Type:

-

new

-

Weight (KG):

-

18000 KG

-

Core Components::

-

Gearbox, Pressure vessel, Pump, Gear, Bearing

-

Key Selling Points::

-

Automatic

-

Product name:

-

High Speed Flexo Printing Slotting Die Cutting Machine

-

Printing colors::

-

1-6 Colors

-

Function::

-

Corrugated Carton Printing Slotting Diecutting

-

Place of origin::

-

Dongguang Cangzhou Hebei China

-

Finished Products::

-

Corrugated Paper Board Carton Boxes

PRODUCT DESCRIPTION

Advanced Flexo Printing Press Machine for High-Quality Printing Results.

Introduction:

DE PACK

The design and manufacture of carton automatic gluing machine meet the requirements of printing, slotting, folding, bonding and stacking. It has the functions of carrying, applying glue, folding and forming several layers automatically. PLC control, touch screen operation, pre storage and management of orders. Its high-speed production capacity, rapidly changing orders and good stability can meet the shorter and shorter delivery cycle requirements of our carton customers.

|

Technological Parameter

|

|

|

|

|||

|

Max Paper Size (W*L)

|

1200x2200mm

|

1450x1200mm

|

1600x1200mm

|

|||

|

Min Paper Size (W*L)

|

440x170mm

|

|

|

|||

|

Maximum stacking height

|

350mm

|

|

|

|||

|

Minimum stacking height

|

80mm

|

|

|

|||

|

Total length

|

12m

|

|

|

|||

|

Max Speed

|

220sheet/min

|

|

|

|||

|

Maximum number of sheets in a pile

|

30sheet

|

|

|

|||

|

Minimum number of sheets in a pile

|

10sheet

|

|

|

|||

|

Maximum size of glue side

|

650mm

|

|

|

|||

|

Maximum dimension of the other side

|

650mm

|

22KW

|

22KW

|

|||

PRODUCT DESPLAY

Paper Feeding Unit:

The paper feeding rubber wheel adopts round multiplexing paper feeding rubber wheel; Frequency conversion control fan, air volume can be freely adjusted, bending cardboard can also be sent smoothly.

Printing unit:

The printing roller adopts the mode of plate hanging, easy to operate, and is equipped with a foot switch to move, convenient to hang plate and erase plate.

Slotted unit:

The upper and lower press roller surface grinding, electroplating hard chromium, smooth correction, smooth operation.

Die cutting unit:

Die-cutting roller surface grinding, electroplating hard chromium, smooth correction, increase running stability; The shaft core is made of steel, which is not easy to break under high pressure.

Adhesive box unit:

The gluing part adopts a roller gluing system, which can track the automatic change of the machine speed. When the machine stops.

Packing unit:

The discharge part adopts the direct push paper discharge mode, which solves the problem of traditional hook discharge and small paperboard collapse.

PROCESS FLOW

COMPANY PROFILE

Cangzhou Depai International Trade Co., Ltd.

was established in 2012 and owns its own brand, DE PACK.

DE PACK is a leading provider of one-stop corrugated carton packaging machinery solutions in the international market. With a dedicated team of experienced professionals, we have established a strong reputation for providing high-quality products and exceptional customer service.

Our core selling points include:

Competitive Pricing:

Our industry expertise allows us to negotiate with suppliers for the best possible prices, enabling us to offer our customers cost-effective solutions. In 2019, we saved our customers a total of $1.5 million through our negotiating power.

Technical Support:

We offer comprehensive technical support and after-sales service to ensure our customers have a smooth and trouble-free experience with our products. In 2022, our technical team provided remote troubleshooting and support to over 80+ customers, with a customer satisfaction rate of 98%.

At DE PACK, we are committed to delivering the best possible solutions and services to our customers, and we will continue to strive for excellence in everything!

PRODUCTION PROCESS

BUYER'S ENDORSEMENT

PACKAGING & LOGISTICS

1. Reinforce containers.

2. Maximize the use of container space to load more machines and reduce logistics costs.

FAQ

Q: What is the lead time of your carton machine?

A: Our production cycle is relatively short, usually within 30-60 days. We can also do expedited production according to customer demand.

A: Our production cycle is relatively short, usually within 30-60 days. We can also do expedited production according to customer demand.

Q: Does your carton machine have after-sales service?

A: Yes, we provide perfect after-sales service, including remote technical support, door-to-door service and so on. Our service team also visits customers regularly to ensure customer satisfaction.

A: Yes, we provide perfect after-sales service, including remote technical support, door-to-door service and so on. Our service team also visits customers regularly to ensure customer satisfaction.

Q: What is the failure rate of the machine?

A: Our machine has been tested and improved many times, and the failure rate is very low. We also provide preventive maintenance services to ensure that machines are kept in good running condition.

A: Our machine has been tested and improved many times, and the failure rate is very low. We also provide preventive maintenance services to ensure that machines are kept in good running condition.

Q: How to ensure the durability and reliability of the machine?

A: High quality steel and castings are selected to ensure that the machine is strong and durable. Perform strict machine performance test and quality inspection to ensure machine reliability. Provide professional maintenance services, prolong the life of the machine.

A: High quality steel and castings are selected to ensure that the machine is strong and durable. Perform strict machine performance test and quality inspection to ensure machine reliability. Provide professional maintenance services, prolong the life of the machine.

Hot Searches