- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CARE

-

Year:

-

Newest

-

Power (kW):

-

11

-

Weight (KG):

-

2800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

PIPE

-

Head:

-

Single head

-

Material:

-

Steel, copper, aluminum etc.

-

Feeding method:

-

Manual feeding

-

Bending:

-

Automatic by hydraulic cylinder

-

Control system:

-

PLC control

-

Power:

-

11kw

-

tube bending machine:

-

stainless steel tube bending machine

Quick Details

-

Machine Type:

-

Bending machine, Pipe and Tube Bending Machine

-

Bending Radius (mm):

-

30 - 350

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CARE

-

Year:

-

Newest

-

Power (kW):

-

11

-

Weight (KG):

-

2800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

PIPE

-

Head:

-

Single head

-

Material:

-

Steel, copper, aluminum etc.

-

Feeding method:

-

Manual feeding

-

Bending:

-

Automatic by hydraulic cylinder

-

Control system:

-

PLC control

-

Power:

-

11kw

-

tube bending machine:

-

stainless steel tube bending machine

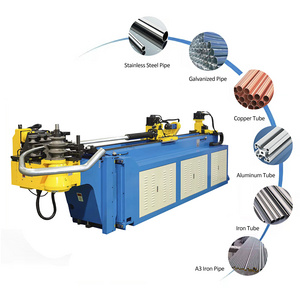

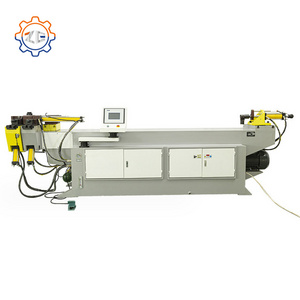

DW89NC Automatic Hydraulic Stainless Steel Tube Bending SS Elbow Bending Machine CNC Pipe Bender

Main specification

1. The machine is controlled by PLC control and driven hydraulically . That can bend various types with different bending angle.

2. It applies English language display and man-machine conversation operation, and can be operated manually, semi automatic and fully automatic mode .

3. It applies hydraulic and electrical elements with high performance.

4. Cooling system with large capacity is provided to control working temperature effectively.

5. The machine has characteristics including easy operation, stable performance, high work efficiency and high safety factor and it is an ideal device for tube processing industry.

6. The movable foot switch has three functions, automatic startup, emergency stop and emergency stop continuity, which ensure high safety.

Technical parameter

|

Specification/Model |

Unit |

DW89NC |

Remark |

|

Max bending capability |

mm |

Φ89×3.5t |

|

|

Max bending radius |

mm |

R350 |

|

|

Min bending radius |

mm |

R25 |

|

|

Max bending angle |

Degree |

185 |

|

|

Max effective distance of mandrel |

mm |

2750 |

|

|

Control System |

|

PLC Control |

|

|

Max elbow bend pipe |

Unit |

16 |

|

|

Max storable sections |

Unit |

16×16 |

|

|

Motor power |

KW |

11 |

|

|

Max. Hydraulic Pressure |

Mpa |

14 |

|

|

Hydraulic System Control |

|

Electromagnetic Valve |

|

|

Oil Tank Capacity |

L |

150 |

|

|

Size |

Cm |

460×108×123 |

|

|

Weight of Machine |

Kg |

≈2900 |

Machine photos

Pipe samples