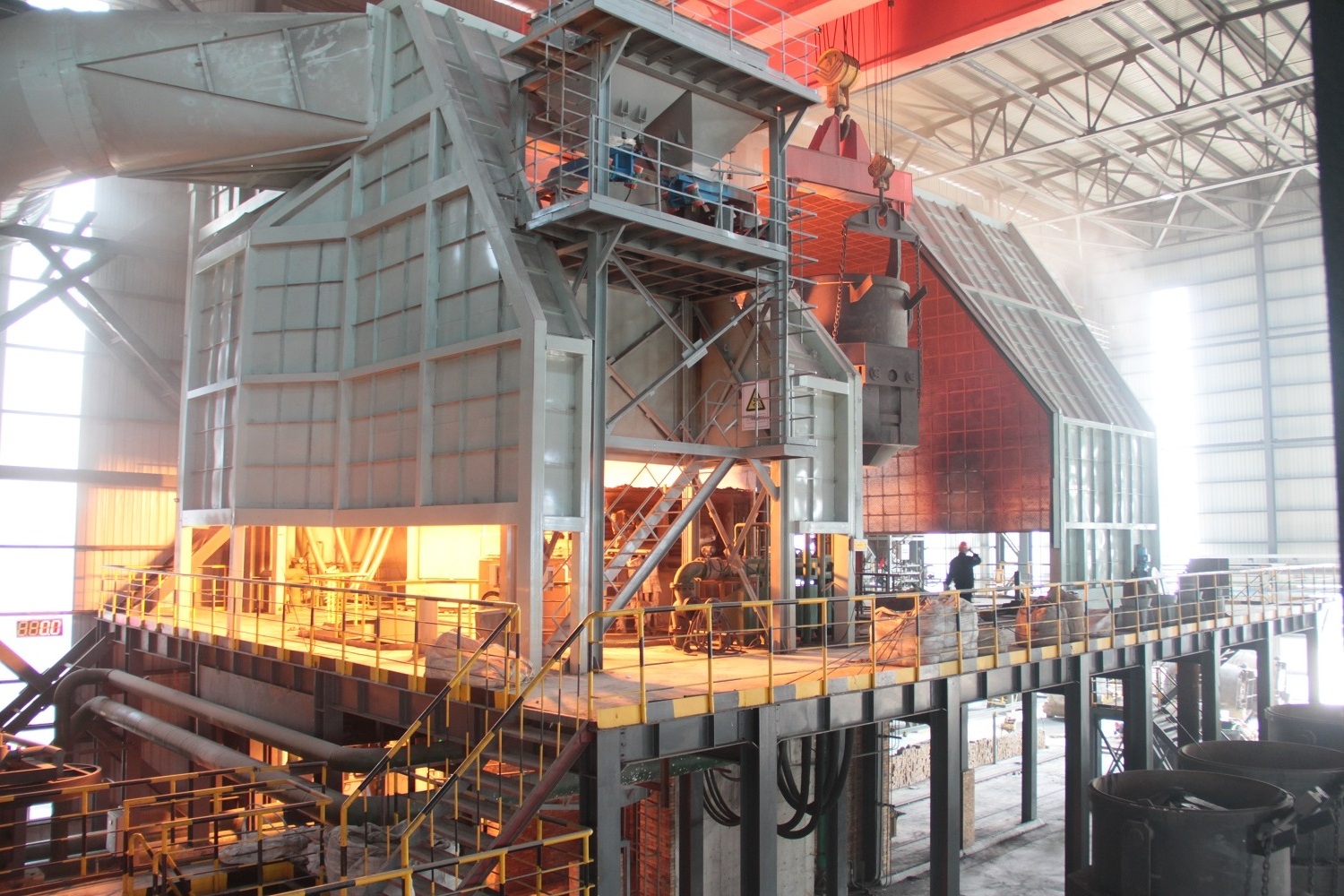

Product features:

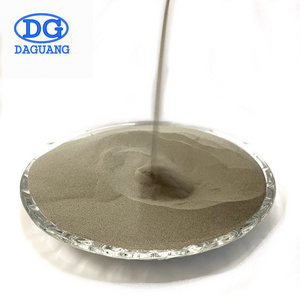

This kind of alloy powder is produced by vacuum atomization. Each particle not only has the same homogeneous chemical composition, but also has ultra-fine grain size, thus eliminating the macrosegregation of the second phase. Compared with the casting material it has higher tensile strength, better toughness and even material hardness.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

High Speed Steel Powder

-

Shape:

-

Powder

-

Material:

-

Alloy

-

Chemical Composition:

-

C;Cr;Co;Mn;Mo;Si;V;W

-

Product name:

-

316L 304L 410L 420 430L 17-4PH Alloy Powder Stainless Steel Powder

-

Color:

-

Grey

-

Flow rate:

-

≤45

-

Apparent density:

-

2.25-2.45

-

Certificate:

-

ISO QA

-

Green density:

-

≥6.00

-

Type:

-

High Speed Steel Powder

-

Standard:

-

ISO 9001 2000

-

Delivery time:

-

7-10 Days

-

MOQ:

-

1kg

Quick Details

-

Application:

-

cutting Tool and Metallurgical Roll

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

KPT

-

Model Number:

-

High Speed Steel Powder

-

Shape:

-

Powder

-

Material:

-

Alloy

-

Chemical Composition:

-

C;Cr;Co;Mn;Mo;Si;V;W

-

Product name:

-

316L 304L 410L 420 430L 17-4PH Alloy Powder Stainless Steel Powder

-

Color:

-

Grey

-

Flow rate:

-

≤45

-

Apparent density:

-

2.25-2.45

-

Certificate:

-

ISO QA

-

Green density:

-

≥6.00

-

Type:

-

High Speed Steel Powder

-

Standard:

-

ISO 9001 2000

-

Delivery time:

-

7-10 Days

-

MOQ:

-

1kg

Characteristics

Higher DC bias characteristics Higher saturation induction density

Lower core loss Better temperature stability

Better corrosion resistance

Higher DC bias characteristics Higher saturation induction density

Lower core loss Better temperature stability

Better corrosion resistance

Products Description

|

Product name

|

High-speed tool steel powder

|

|

Color

|

Grey

|

|

Application

|

cutting tool;metallurgical roll ; Cold-work Die

|

|

Certifications

|

REACH, ISO

|

|

appearance

|

Visible Impurities

|

|

Physical properties of magnetic powder

|

|

|

|

|

|

|||||

|

Products

|

Process

|

D50 (um)

|

T.D

|

o.c.

|

Specifications (mesh)

|

|||||

|

|

|

|

(g/cm3)

|

(ppm gas)

|

|

|||||

|

NHPM3

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|||||

|

NHPM4

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|||||

|

NHPT15

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|||||

|

NHPT15M

|

Gas atomization

|

50-100

|

≥4.7

|

≤600

|

40/500

|

|||||

|

NHP10V

|

Gas atomization

|

50-100

|

≥4.6

|

≤600

|

40/500

|

|||||

|

NHP23

|

Gas atomization

|

50-100

|

≥5.0

|

≤500

|

40/500

|

|||||

|

NHP30

|

Gas atomization

|

50-100

|

≥5.0

|

≤500

|

40/500

|

|||||

Product Application:

Hot Searches