- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Smart

-

Voltage:

-

56kw

-

Dimension(L*W*H):

-

3300*1300*2150cm

-

Hollow part volume:

-

100000ml

-

Clamping Force (kN):

-

1500

-

Power (kW):

-

54

-

Weight (KG):

-

3100 KG

-

Automatic:

-

Yes

-

Model Number:

-

SM-800D

-

Cavity:

-

1

-

Max Bottle Volume:

-

10L

-

Output:

-

600bph

-

Preform Jigs:

-

54Pcs

-

Sensor Switch:

-

SICK

-

Keywords:

-

Full automatic Blow Machine

-

Product name:

-

10L pet bottle blowing machine

-

Suitable bottle:

-

Oil Water drinking PET bottle

-

Certification:

-

according ISO9001:2000

Quick Details

-

Neck Diameter(mm):

-

50 mm

-

Max.Bottle Diameter(mm):

-

220 mm

-

Max.Bottle Height(mm):

-

450 mm

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Smart

-

Voltage:

-

56kw

-

Dimension(L*W*H):

-

3300*1300*2150cm

-

Hollow part volume:

-

100000ml

-

Clamping Force (kN):

-

1500

-

Power (kW):

-

54

-

Weight (KG):

-

3100 KG

-

Automatic:

-

Yes

-

Model Number:

-

SM-800D

-

Cavity:

-

1

-

Max Bottle Volume:

-

10L

-

Output:

-

600bph

-

Preform Jigs:

-

54Pcs

-

Sensor Switch:

-

SICK

-

Keywords:

-

Full automatic Blow Machine

-

Product name:

-

10L pet bottle blowing machine

-

Suitable bottle:

-

Oil Water drinking PET bottle

-

Certification:

-

according ISO9001:2000

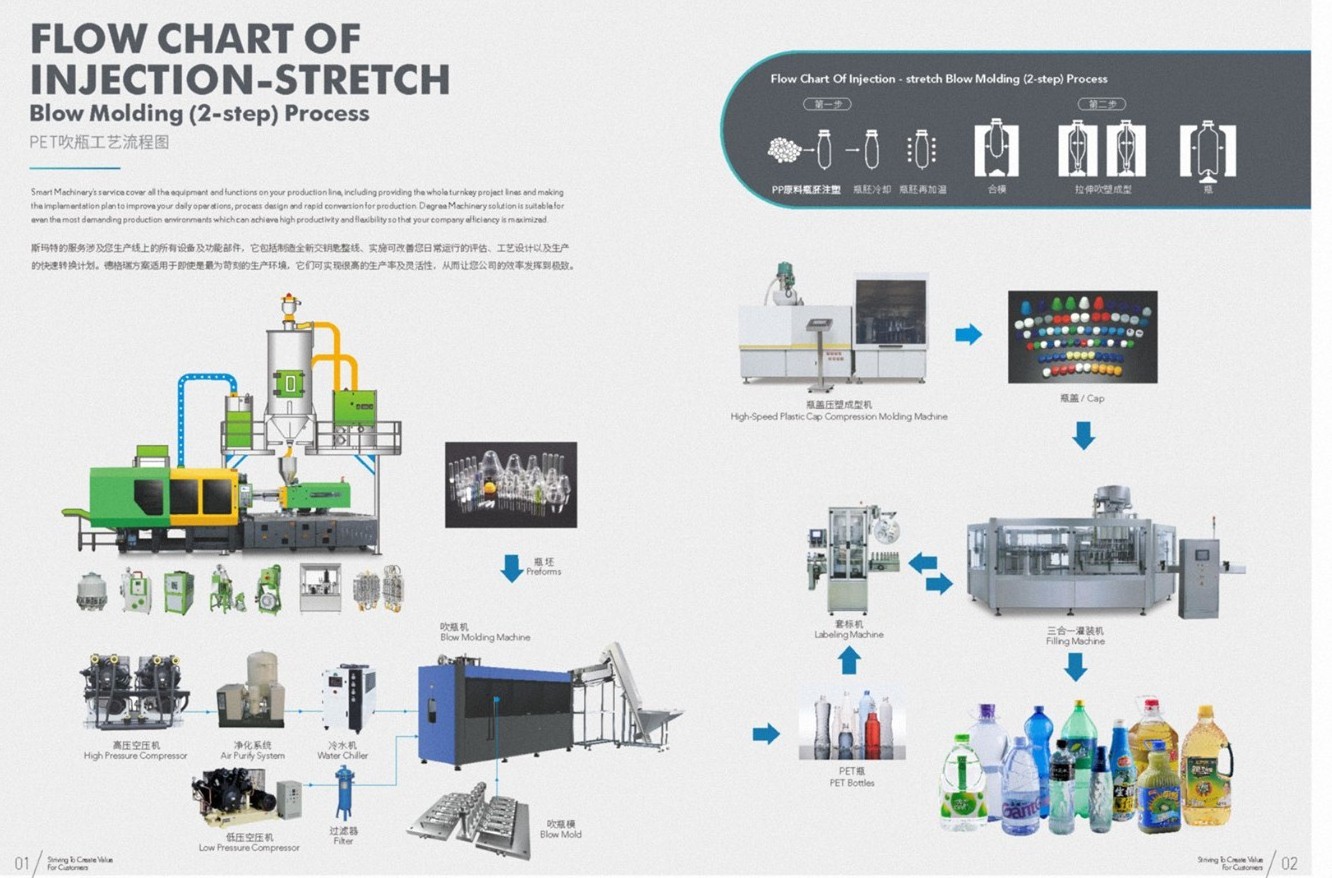

Features of cooking oil bottle blowing machine :

1. Stable and fine performance with advanced PLC.

2. Conveying perform automatically with conveyor.

3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

4. Well adjustability to enable the preheater to preheat preform in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

5.High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

6.No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8. Strong clamping force with high pressure and double crank links to lock the mold.

9. Low cost, high efficiency, easy operation, good interchangeability, easy maintenance, etc, with automatic technological process.

Advantage:

1.we are factory, the quality ensured, Safety;

2.Faster delivery, 2cavity PET bottle blow molding machine;

3.suitable for different preform neck size (the Preform jigs can exchangeable);

4.more easy to operate;

After sales service

*

Instruction for Installation and Debugging

Before delivery, SMART takes responsible for debugging of cooking oil bottle blowing machine ,

in order to make sure the provided machine could be safely and smoothly put into operation.

SMART also take responsibility to have debugging overseas, and Client abroad please sends invitation forward of time to engineer of SMART, provides the engineer with round-trip tickets, accommodation, vehicle and salary.

* User Training

Technical training will be provided by SMART before delivery so that users would understand the machine features and how to operate the machine by themselves.

* Warranty Period

The warranty period for SMART machine is one year with a lifelong maintenance. If there is special requirement, other stipulated warranty period may be made after mutual agreement.