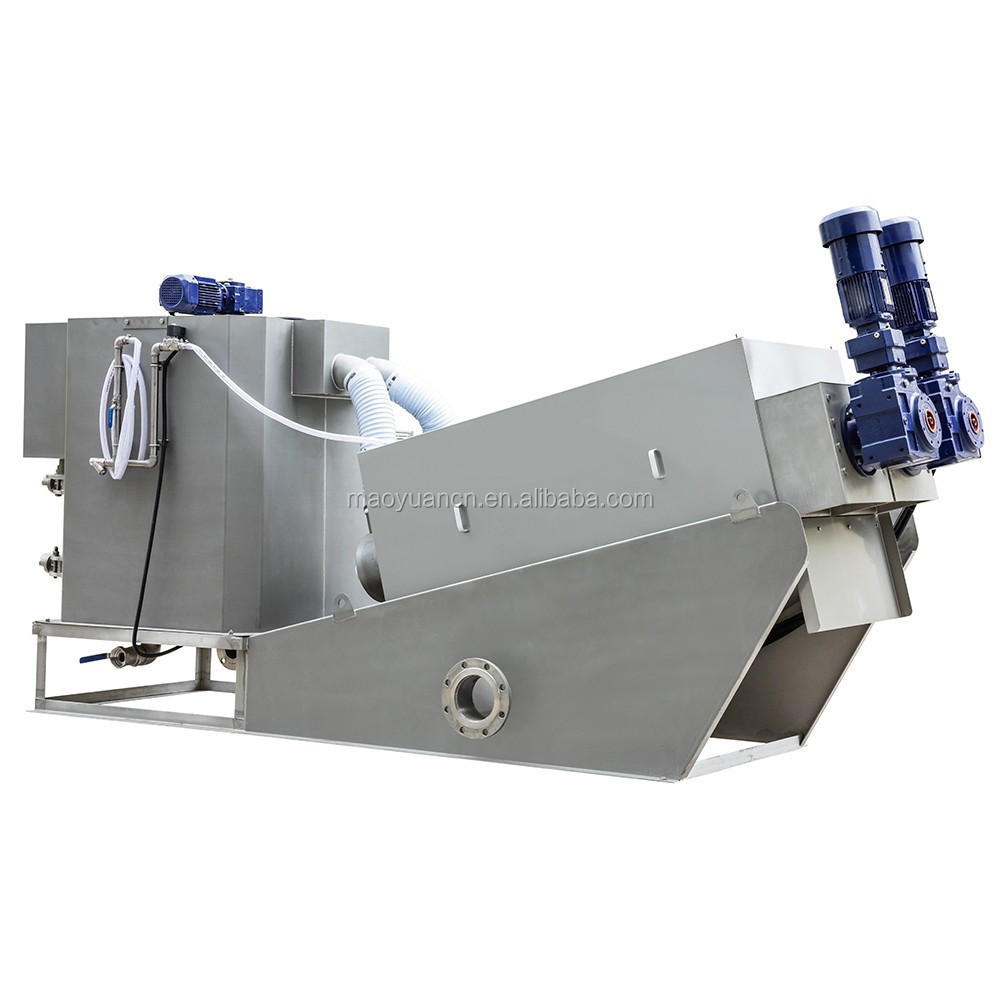

Sludge firstly will be thickened thickening zone. In the advancing process, with the decreasing spacing and smaller gap distance in dewatering zone, the screw body has giant pressure that the purpose of fully dewatering will be achieved.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Different due to models

-

Size:

-

Different due to models

-

Power:

-

Different due to models

-

Warranty:

-

18 Months

-

Weight (KG):

-

300 kg

-

Operation:

-

Fully automatic

-

Advantages:

-

No clogging

-

Features:

-

Energy saving

-

Processing:

-

Laser cutting

-

Product name:

-

Sludge Dewatering Machine

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MYEP

-

Material:

-

Wood package, SS304 or SS316

-

Weight:

-

Different due to models

-

Size:

-

Different due to models

-

Power:

-

Different due to models

-

Warranty:

-

18 Months

-

Weight (KG):

-

300 kg

-

Operation:

-

Fully automatic

-

Advantages:

-

No clogging

-

Features:

-

Energy saving

-

Processing:

-

Laser cutting

-

Product name:

-

Sludge Dewatering Machine

-

Certification:

-

CE ISO

Screw Press Sludge Dewatering Machine is widely used in municipal wastewater treatment engineering, petrochemical, light industry, chemical fiber, paper making, pharmaceutical, leather and other industries. The actual operation shows that the sludge dewatering can

create considerable economic benefits and social benefits for the customers.

Model Selection

|

Model

|

Dry sludge

Capacity

|

Capacity to Flow with different Solids Content

|

|

|

|

|

||||

|

|

|

10000mg/L

|

20000mg/L

|

30000mg/L

|

40000mg/L

|

50000mg/L

|

||||

|

MYEP131

|

10~14KG/h

|

1m³/h

|

0.5m³/h

|

0.4m³/h

|

0.3m³/h

|

0.26m³/h

|

||||

|

MYEP201

|

15~20KG/h

|

1.5m³/h

|

0.75m³/h

|

0.6m³/h

|

0.5m³/h

|

0.4m³/h

|

||||

|

MYEP202

|

30~40KG/h

|

3m³/h

|

1.5m³/h

|

1.2m³/h

|

1m³/h

|

0.8m³/h

|

||||

|

MYEP301

|

50~70KG/h

|

5m³/h

|

2.5m³/h

|

2m³/h

|

1.5m³/h

|

1.4m³/h

|

||||

|

MYEP302

|

100~140KG/h

|

10m³/h

|

5m³/h

|

4m³/h

|

3m³/h

|

2.8m³/h

|

||||

|

MYEP303

|

150~210KG/h

|

15m³/h

|

7.5m³/h

|

6m³/h

|

4.5m³/h

|

4.2m³/h

|

||||

|

MYEP351

|

100~120KG/h

|

10m³/h

|

5m³/h

|

4m³/h

|

3m³/h

|

2.4m³/h

|

||||

|

MYEP352

|

200~240KG/h

|

20m³/h

|

10m³/h

|

8m³/h

|

6m³/h

|

4.8m³/h

|

||||

|

MYEP353

|

300~360KG/h

|

30m³/h

|

15m³/h

|

12m³/h

|

9m³/h

|

7.2m³/h

|

||||

|

MYEP401

|

130~160KG/h

|

13m³/h

|

6.5m³/h

|

5m³/h

|

4m³/h

|

3.2m³/h

|

||||

|

MYEP402

|

260~320KG/h

|

26m³/h

|

13m³/h

|

10m³/h

|

8m³/h

|

6.4m³/h

|

||||

|

MYEP403

|

390~480KG/h

|

39m³/h

|

19.5m³/h

|

15m³/h

|

12m³/h

|

9.6m³/h

|

||||

|

MYEP404

|

520~640KG/h

|

52m³/h

|

26m³/h

|

20m³/h

|

16m³/h

|

12.8m³/h

|

||||

Main Features

1) 24hours automatic and continuous running.

2) Good at dealing with Oily sludge.

3) Easy installation and maintenance.

4) Water and power saving.

Dewatering Principle

Before Treatment

*Moisture Content Range: 99.8~92%

*Directly Treat Sludge in the tank

*No need for sludge thickening tank

After Treatment

*Oultet Moisture Content:75~85%

*Compacy design, simple structure

*Saving cost of civil engineering

Screw Bodys

Mainly composed of fixed and moving rings.

Thickening and dewatering can be finished in one part.

Reducer & Motor

First class brand, SEW, NORD or other brands are optional due to your actual needs.

Excellent performance to ensure a long services lifespan.

Electric control panel

Frequency converting controls dewatering body.

Realize the switch of automatic and manual running.

|

Packaging

|

|

|

|

Size

|

Different due to models

|

|

|

Weight

|

Different due to models

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

|

Delivery

|

|

|

|

Loading port

|

Shanghai port

|

|

|

Delivery time

|

One set usually 30~45 days

|

|

|

|

|

|

For more information, welcome to contact with me below. We will be glad to help you.