- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YW TAIYANG HEATERS

-

Dimension(L*W*H):

-

customized

-

Weight:

-

0.5 KG

-

Working Temperature Range:

-

0 - 800 ℃

-

Core Components:

-

Other

-

Product name:

-

Cartridge Heater Element

-

Wattage:

-

Customized

-

Size:

-

Customized

-

Certification:

-

CE Certification

-

Keywords:

-

Electric Cartridge Heater

-

After-sales Service Provided:

-

On-line Support

-

Application:

-

Industry Heating Process

-

Marketing Type:

-

Hot Product

Quick Details

-

Type:

-

Cartridge Heater

-

Power Source:

-

Electric

-

Voltage:

-

12-480V or customized, 12V-480V/Customizable

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YW TAIYANG HEATERS

-

Dimension(L*W*H):

-

customized

-

Weight:

-

0.5 KG

-

Working Temperature Range:

-

0 - 800 ℃

-

Core Components:

-

Other

-

Product name:

-

Cartridge Heater Element

-

Wattage:

-

Customized

-

Size:

-

Customized

-

Certification:

-

CE Certification

-

Keywords:

-

Electric Cartridge Heater

-

After-sales Service Provided:

-

On-line Support

-

Application:

-

Industry Heating Process

-

Marketing Type:

-

Hot Product

Wholesale 12V 24V 48V 1000W Cartridge Immersion Heater With Thermocouple

Product Overview

|

Product name

|

Cartridge Heater Element

|

|

Voltages available

|

12V—380V, Customized

|

|

Max operating temp

|

870

o

C(1600F)

|

|

Wattage Tolerance

|

+5%, -10%

|

|

Resistance heating wire material

|

Cr20Ni80

|

|

Resistance tolerance

|

+10%, -5%

|

|

Tube material

|

SS304,SS316,SS310S,SS321,INCOLOY 800,INCOLOY 840

|

|

Tube diameter

|

3-30mm,customized

|

|

Diameter tolerance

|

± 0.02mm

|

|

Tube length

|

Customized

|

|

Length tolerance

|

±1 mm

|

|

Cold Zone

|

Customized

|

|

Insulation resistance (cold)

|

≥ 500 MΩ

|

|

Maximum leakage current (cold)

|

≤ 0.5 mA

|

|

Thermocouple Location

|

type J / K /E/ Ground wire

|

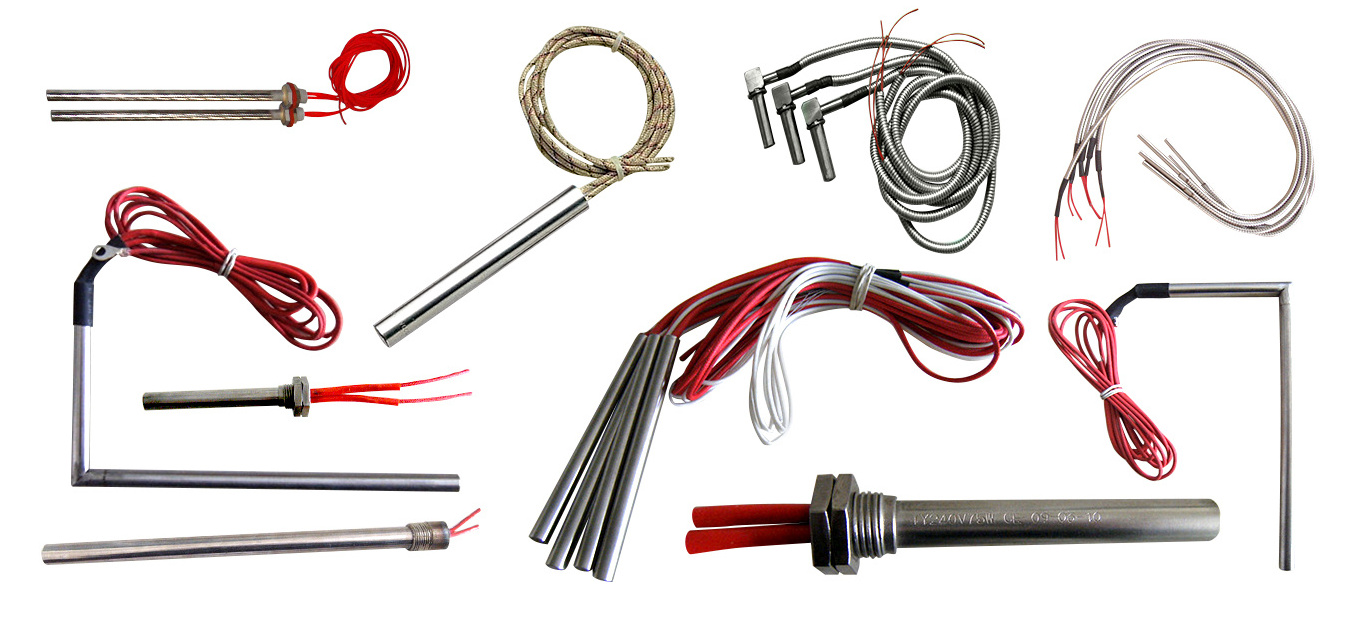

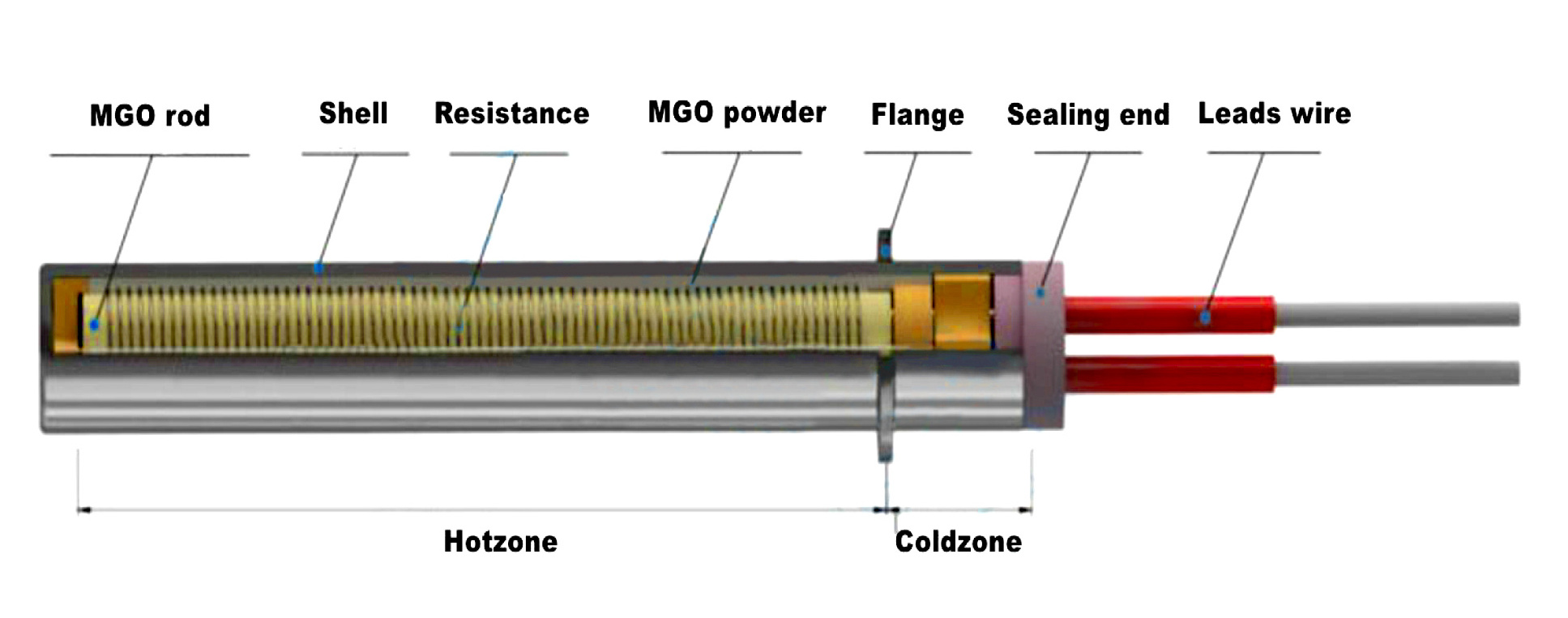

Cartridge heaters

Cartridge heaters are simply the benchmark of industry. Plastic processing, food-service, and process industries alike look to our cartridge heaters as a reliable, efficient and cost-effective heat source.

Cartridge heaters

are made for use in applications where high density, high temperatures, and long service life are critical to reduce downtime and minimize cost.

Product Details

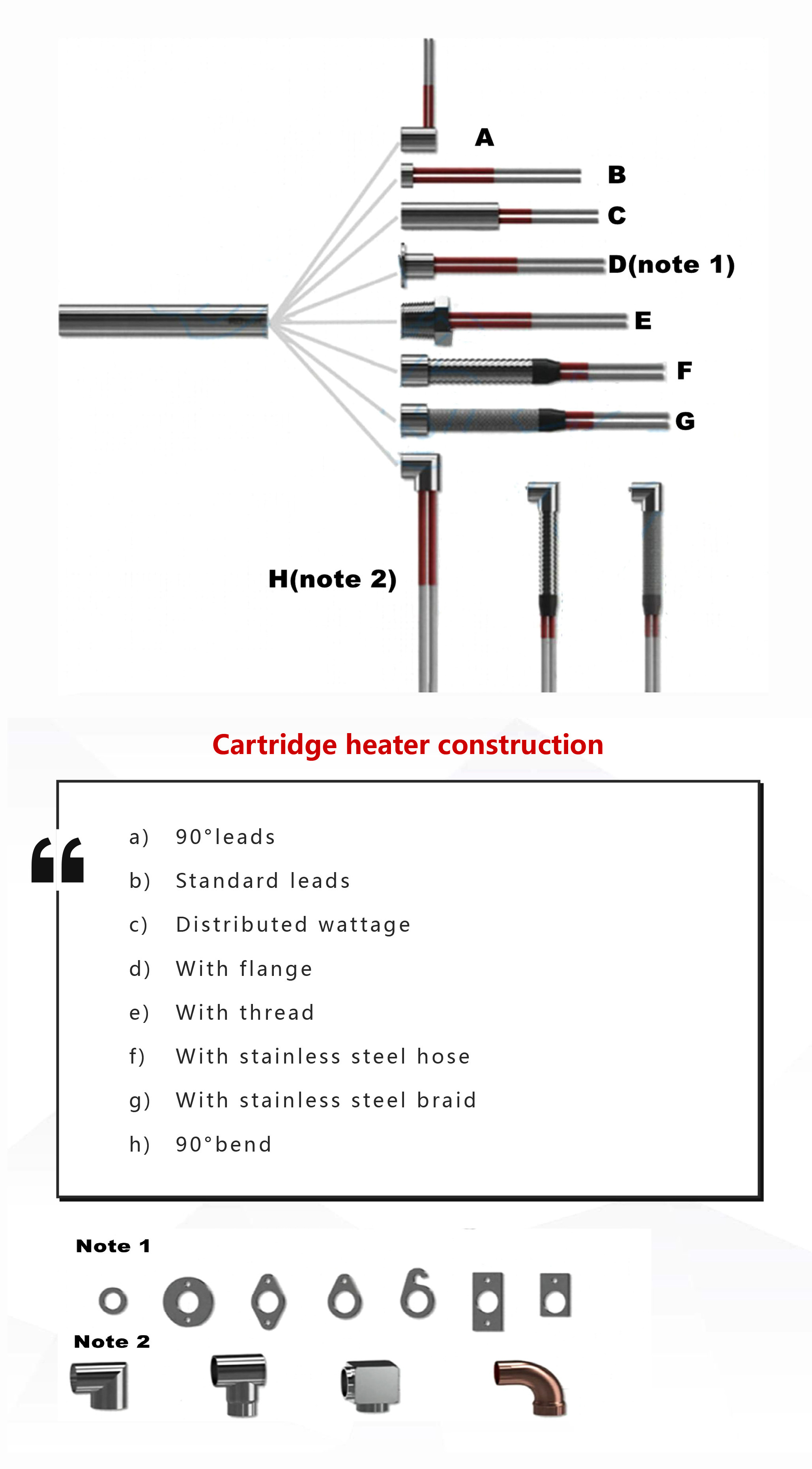

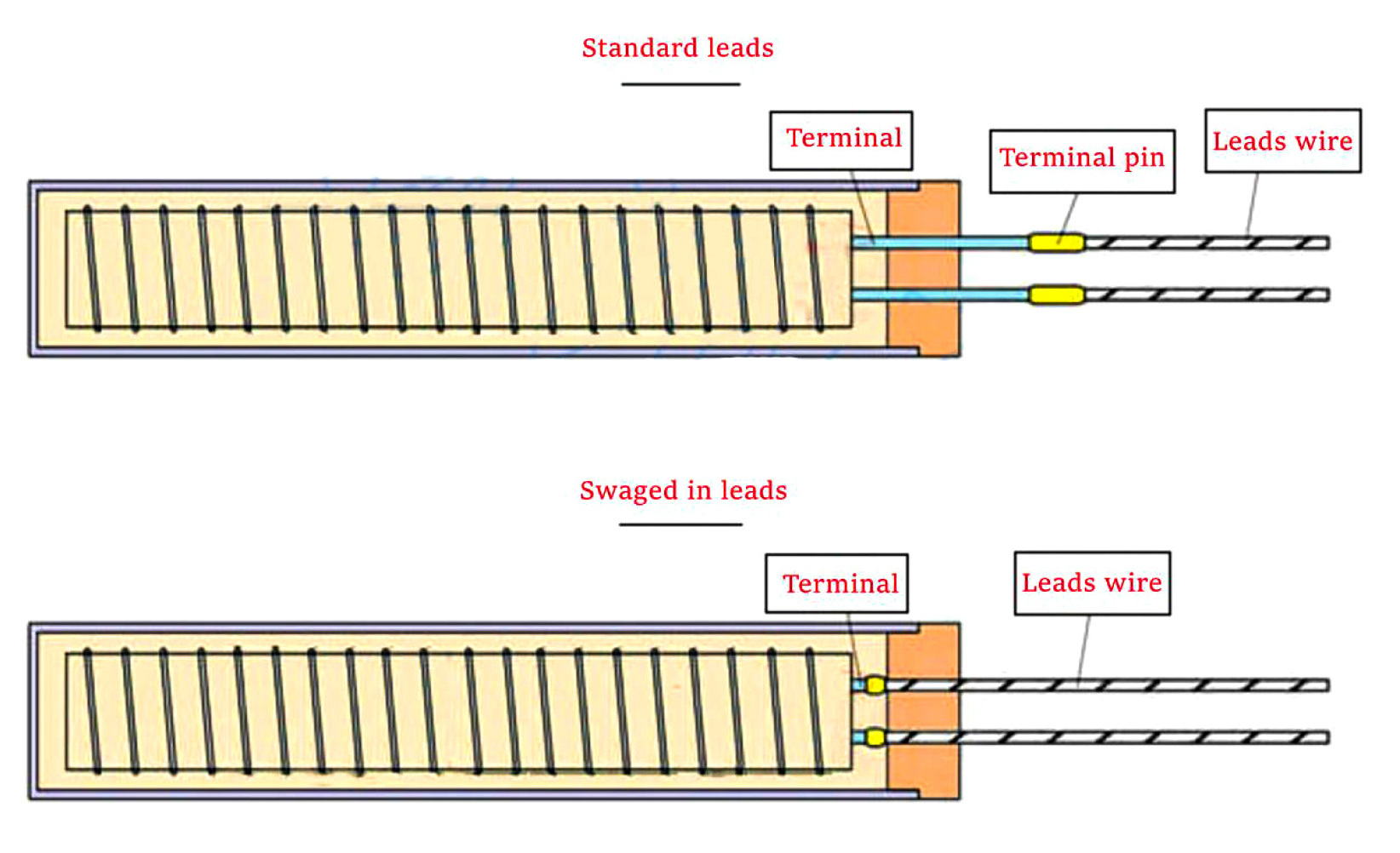

Standard Leads

Fiberglass insulated lead-wires are externally connected to nickel pins. The connection area is electrically insulated with heavy-wall fiberglass sleeving. 12” leads are standard. Specify longer leads if required.

Swaged in flexible leads

Fiberglass insulated lead-wires are internally connected to nickel pins. This design allows for great flexibility at the lead exit point of the heater. 12” leads are standard.

Specify longer leads if required.

Teflon leads and seal

Teflon insulated lead-wires with a Teflon end seal swaged into the heater sheath provides a moisture resistant design. This design

requires a minimum of 1” cold section at lead exit end of heater. 12” leads are standard.

Specify longer leads if required.

requires a minimum of 1” cold section at lead exit end of heater. 12” leads are standard.

Specify longer leads if required.

Right angle leads

Fiberglass insulated leads exit at a right angle from the heater sheath.

Specify overall length of heater.

Specify overall length of heater.

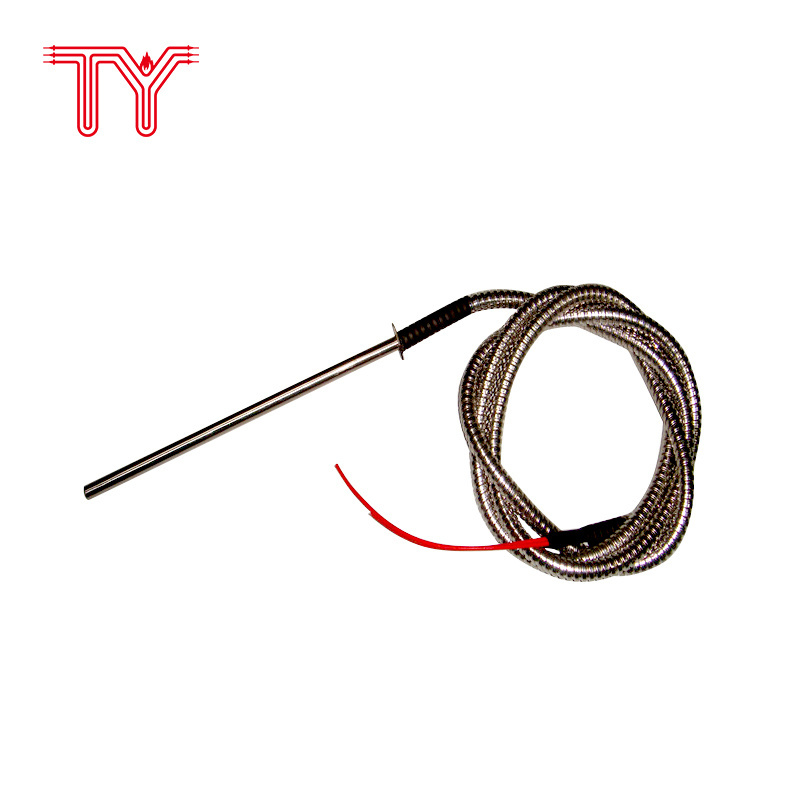

Straight braid leads

Stainless steel braid over fiberglass insulated lead-wires exits straight from heater sheath for abrasion resistance, yet is flexible enough for sharp bends. 3’’ additional lead beyond braid is standard.

Specify longer lead if required

Specify longer lead if required

Internal thermocouple

Type K, J thermocouple provides an integral method for temperature control. Thermocouple junction (grounded or ungrounded) can be located at the end disc, center, or lead end. Please specify.

Other thermocouple types are available.

Other thermocouple types are available.

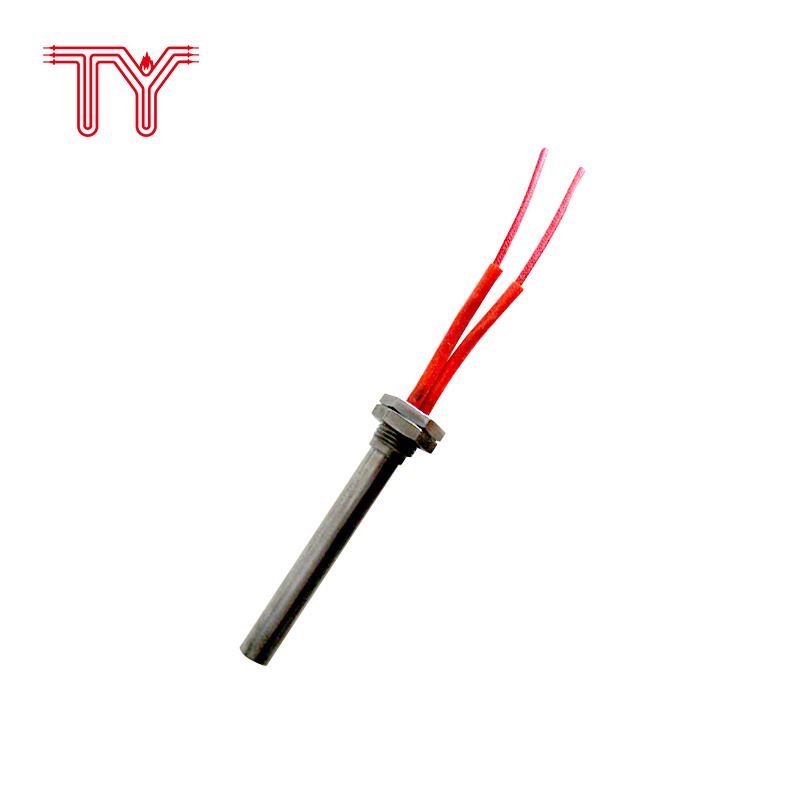

Immersion pipe fitting

Threaded pipe fitting is silver soldered or welded directly to heater sheath for immersion applications. Fiberglass insulated lead-wires exit high temperature cement potting.

3/4” cold required before fitting.

Specify: stainless fitting or brass fitting.

Specify: stainless fitting or brass fitting.

Mounting flange

Stainless steel flange welded directly to heater sheath. Fiberglass insulated lead-wires are standard.

Other flange sizes and hole patterns

are available upon request.

Other flange sizes and hole patterns

are available upon request.

Finned cartridge heater

Finned cartridge heaters provide rapid

heat transfer for natural convection or

forced air space heating in industrial process air heating systems. Finned cartridge heaters start out as a standard cartridge heater with the fins being attached on a custom built finning machine.

heat transfer for natural convection or

forced air space heating in industrial process air heating systems. Finned cartridge heaters start out as a standard cartridge heater with the fins being attached on a custom built finning machine.

For m ore heaters,you can contact with us to customize for you

When ordering Cartridge Heaters, specify the following:

1. Nominal Diameter - see specifications for assistance.

2. Overall Sheath Length - measured in inches or millimeters from end to end of heater sheath.

3. Lead Length - specify in inches.

4. Termination Type - see following pages for assistance.

5. Voltage - specify

6. Wattage - specify

7. Special Modifications - specify as required.

1. Nominal Diameter - see specifications for assistance.

2. Overall Sheath Length - measured in inches or millimeters from end to end of heater sheath.

3. Lead Length - specify in inches.

4. Termination Type - see following pages for assistance.

5. Voltage - specify

6. Wattage - specify

7. Special Modifications - specify as required.

Special modifications

In addition to the standard design, TY offers a variety of special modifications which are available to customize the heater for your application.

Distributed Wattage: Resistance winding can be concentrated in specific areas of the heater

for localized heat distribution.

Centerless Grinding: Precision grinding of the heater sheath provides tighter diameter

tolerances when required.

Teflon Coating: Teflon coating can be provided on heater sheath for applications

requiring chemical resistance.

Ground Lead-wire: Separate color coded ground wire can be provided when required.

Special Connectors: Various connectors for power leads can be provided upon request.

Distributed Wattage: Resistance winding can be concentrated in specific areas of the heater

for localized heat distribution.

Centerless Grinding: Precision grinding of the heater sheath provides tighter diameter

tolerances when required.

Teflon Coating: Teflon coating can be provided on heater sheath for applications

requiring chemical resistance.

Ground Lead-wire: Separate color coded ground wire can be provided when required.

Special Connectors: Various connectors for power leads can be provided upon request.

Cartridge care and maintenance

1. Store heaters in a dry area, especially during periods of high humidity.

2. Protect leads from abuse and abrasion.

3. Maintain temperature control and keep accessories in good working condition to obtain correct operating conditions.

4. All cartridge heaters have hygroscopic tendencies and can accumulate moisture in shipping and storage. Low heater insulation (less then 1 meg ohm) can be baked in an oven for several hours or started at low voltage to eliminate moisture.

1. Store heaters in a dry area, especially during periods of high humidity.

2. Protect leads from abuse and abrasion.

3. Maintain temperature control and keep accessories in good working condition to obtain correct operating conditions.

4. All cartridge heaters have hygroscopic tendencies and can accumulate moisture in shipping and storage. Low heater insulation (less then 1 meg ohm) can be baked in an oven for several hours or started at low voltage to eliminate moisture.

Factors for longer heater life

1. Do not exceed recommended maximum watt density specified for the heater size.

2. The heater sheath must fit properly into the machined hole. A tight fit is critical.

3. Protect the heater from contaminants such as oil, grease, and vapors.

4. Install adequate Kw to accomplish work load and make up for heat losses.

1. Do not exceed recommended maximum watt density specified for the heater size.

2. The heater sheath must fit properly into the machined hole. A tight fit is critical.

3. Protect the heater from contaminants such as oil, grease, and vapors.

4. Install adequate Kw to accomplish work load and make up for heat losses.

Customer Reviews

Certifications

YW TAIYANG HEATERS

All products

have one year quality warranty.

Our Advantages

Hot Searches