- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8.0*3.75*3.8m

-

Weight:

-

33 ton

-

Product name:

-

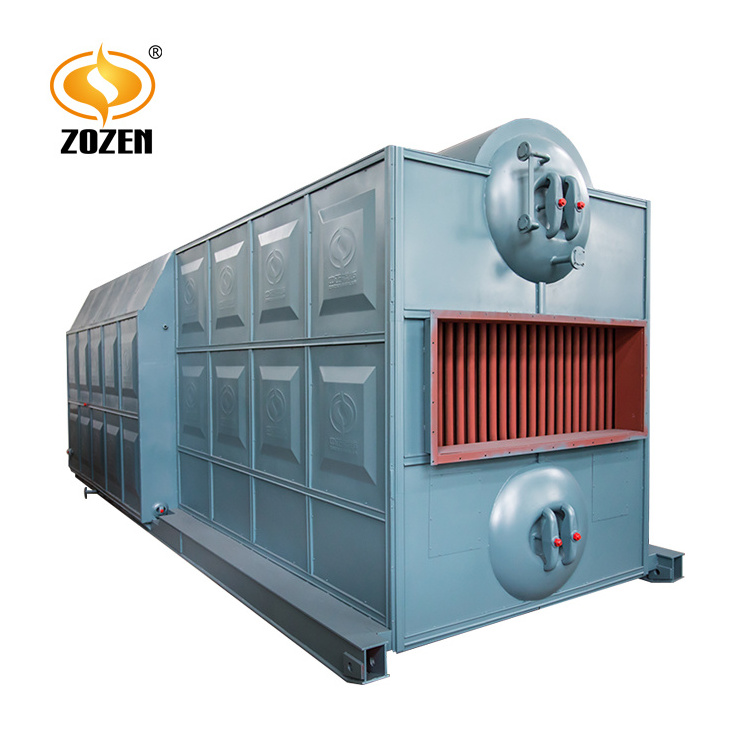

Coal Fired Steam Boiler

-

Product thermal capacity:

-

4-35 t/h

-

Outlet temperature:

-

184-350 ℃

-

Feature:

-

Low Operating Cost

-

Available fuel:

-

Bituminous coal, lean coal, anthracite

-

Available industries:

-

Heating, chemical, food, tobacco,building materials

-

Operation:

-

Industrial Intelligent Controller

-

Boiler:

-

Steam Boiler

-

Advantages:

-

Top 1 A-Class Boiler

-

Color:

-

Customer's Requirement

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Philippines, Indonesia, Pakistan, Thailand, Malaysia, Australia, Bangladesh, Kazakhstan, Kyrgyzstan, Uzbekistan

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ASME PED GB

Quick Details

-

Core Components:

-

water tube

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZOZEN

-

Dimension(L*W*H):

-

8.0*3.75*3.8m

-

Weight:

-

33 ton

-

Product name:

-

Coal Fired Steam Boiler

-

Product thermal capacity:

-

4-35 t/h

-

Outlet temperature:

-

184-350 ℃

-

Feature:

-

Low Operating Cost

-

Available fuel:

-

Bituminous coal, lean coal, anthracite

-

Available industries:

-

Heating, chemical, food, tobacco,building materials

-

Operation:

-

Industrial Intelligent Controller

-

Boiler:

-

Steam Boiler

-

Advantages:

-

Top 1 A-Class Boiler

-

Color:

-

Customer's Requirement

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Philippines, Indonesia, Pakistan, Thailand, Malaysia, Australia, Bangladesh, Kazakhstan, Kyrgyzstan, Uzbekistan

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ASME PED GB

Introduction

SZL series vertical dual drums chain grate water tube steam and hot water boiler, adopts quick fitting and assembly structure. The 4-6t/h boiler is of quick fitting tube structure, exit shop after completely assembled, the boiler of 6-35t/h is composed of 2 main components. The upper assembled component is the boiler proper heat absorbing part, and the lower assembled component is of combustion equipment. The former part of the boiler proper is arranged a membrane wall, the upper part of it is connected to boiler cylinder, and its lower part is connected to collective chest, so as to form a combustion room and absorb the radiated heat from the furnace. Its rear part is arranged with dense convection tubes between upper and lower boiler cylinders. The high temperature smog after combustion shall stand for twice returning flushing transversely to the heat accepting surfaces, and shall be introduced to coal saver singly arranged, and flow into duster and exhausted from chimney in the end.

|

Model

|

Rated evaporation(t/h)

|

Rated working pressure(MPa

|

Rated steam temperature

|

Thermal efficiency(%)

|

|

SZL4-1.25-AI

|

4

|

1.25

|

194

|

82.8

|

|

SZL4-1.60-AI

|

4

|

1.6

|

204

|

82.8

|

|

SZL4-2.45-AI

|

4

|

2.45

|

225

|

82.8

|

|

SZL6-1.25-AⅡ

|

6

|

1.25

|

194

|

82.8

|

|

SZL6-1.60-AⅡ

|

6

|

1.6

|

204

|

82.8

|

|

SZL6-2.45-AⅡ

|

6

|

2.45

|

225

|

82.8

|

|

SZL8-1.25-AⅡ

|

8

|

1.25

|

194

|

83.2

|

|

SZL8-1.60-AⅡ

|

8

|

1.6

|

204

|

83.2

|

|

SZL8-2.45-AⅡ

|

8

|

2.45

|

225

|

83.2

|

|

SZL10-1.25-AⅡ

|

10

|

1.25

|

194

|

83.2

|

|

SZL10-1.60-AⅡ

|

10

|

1.6

|

204

|

83.2

|

|

SZL10-2.45-AⅡ

|

10

|

2.45

|

225

|

83.2

|

|

SZL20-1.25-AⅡ

|

20

|

1.25

|

194

|

85.8

|

|

SZL20-1.60-AⅡ

|

20

|

1.6

|

204

|

85.8

|

|

SZL20-2.45-AⅡ

|

20

|

2.45

|

225

|

85.8

|

|

SZL30-1.25-AⅡ

|

30

|

1.25

|

194

|

86

|

|

SZL30-1.60-AⅡ

|

30

|

1.6

|

204

|

86

|

|

SZL30-2.45-AⅡ

|

30

|

2.45

|

22 5

|

86

|

|

SZL35-1.25-AI

|

35

|

1.25

|

194

|

82.8

|

|

SZL35-1.60-AI

|

35

|

1.6

|

204

|

82.8

|

|

SZL35-2.45-AI

|

35

|

2.45

|

225

|

82.8

|