Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMCO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20M*2.8M*2.9M

-

Power (kW):

-

180

-

Weight:

-

15000 KG

-

Name:

-

EPE foam Sheet Making Machine

-

Raw material:

-

EPE material

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Marketing Type:

-

Hot product 2024

-

Usage:

-

plastic flooriing sheet making

-

Final product:

-

EPE packing sheet

-

Processing Type:

-

Exturding Machine

-

Keywords:

-

plastic sheet line

-

Inverter:

-

ABB Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

72 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMCO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20M*2.8M*2.9M

-

Power (kW):

-

180

-

Weight:

-

15000 KG

-

Name:

-

EPE foam Sheet Making Machine

-

Raw material:

-

EPE material

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Marketing Type:

-

Hot product 2024

-

Usage:

-

plastic flooriing sheet making

-

Final product:

-

EPE packing sheet

-

Processing Type:

-

Exturding Machine

-

Keywords:

-

plastic sheet line

-

Inverter:

-

ABB Brand

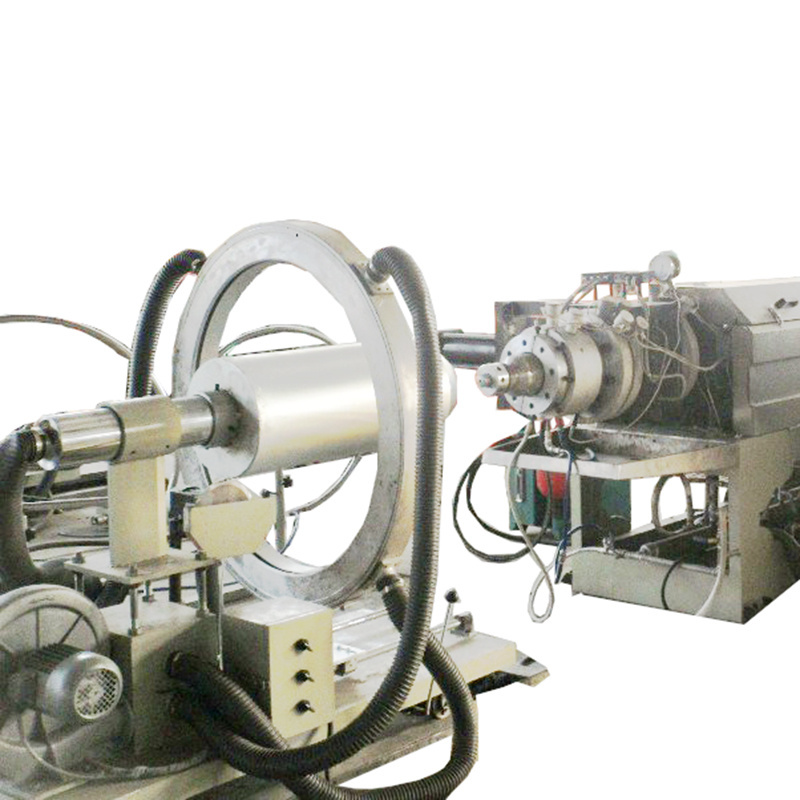

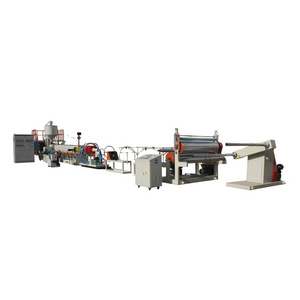

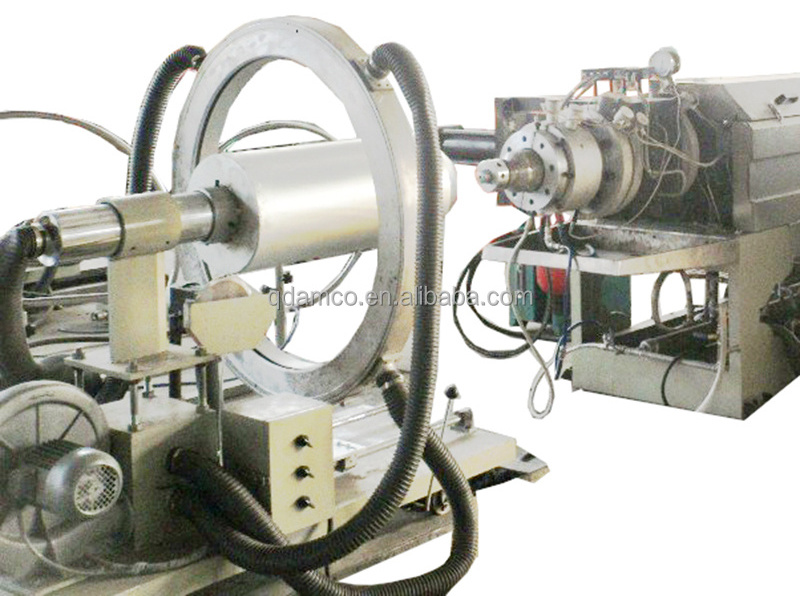

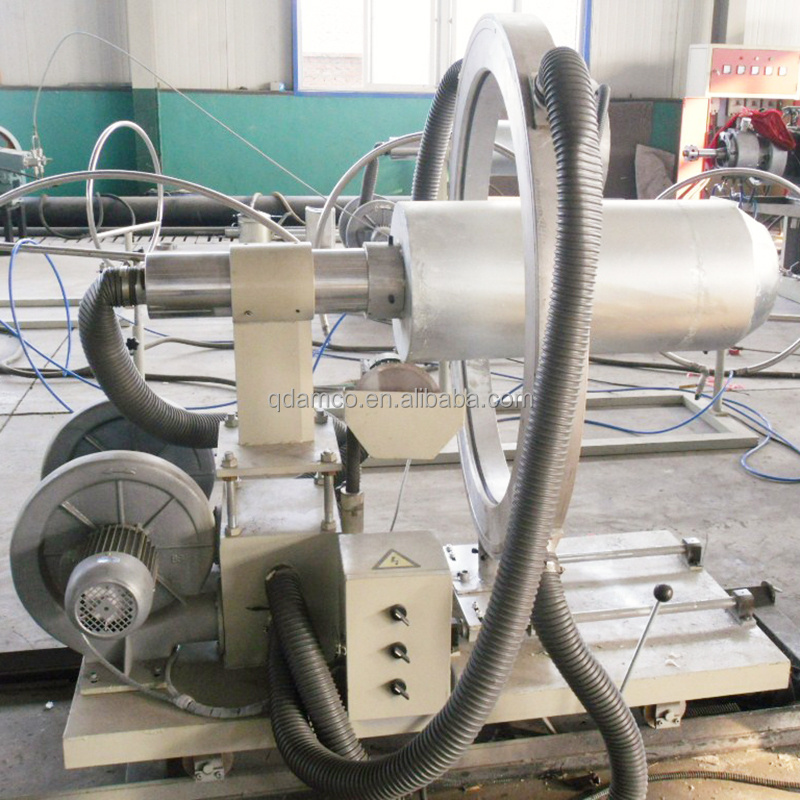

EPE Foam Cloth (for Package) Production Line

1. EPE foam cloth application:

T he EPE foam cloth is also refers to as pearl cotton, is a newly designed packaging material, has good looking, low cost and good performance; it is the ideal package mterial to replace the traditional package material. The EPE foam cloth is widely used to package home appliance, precise elements, bicycle, shoes, bike cycle , glass and

high-grade porcelain , etc. The foamed sheet can be laminated by other material, and also can be thickened up to 100mm according to customer ’ s requirement.

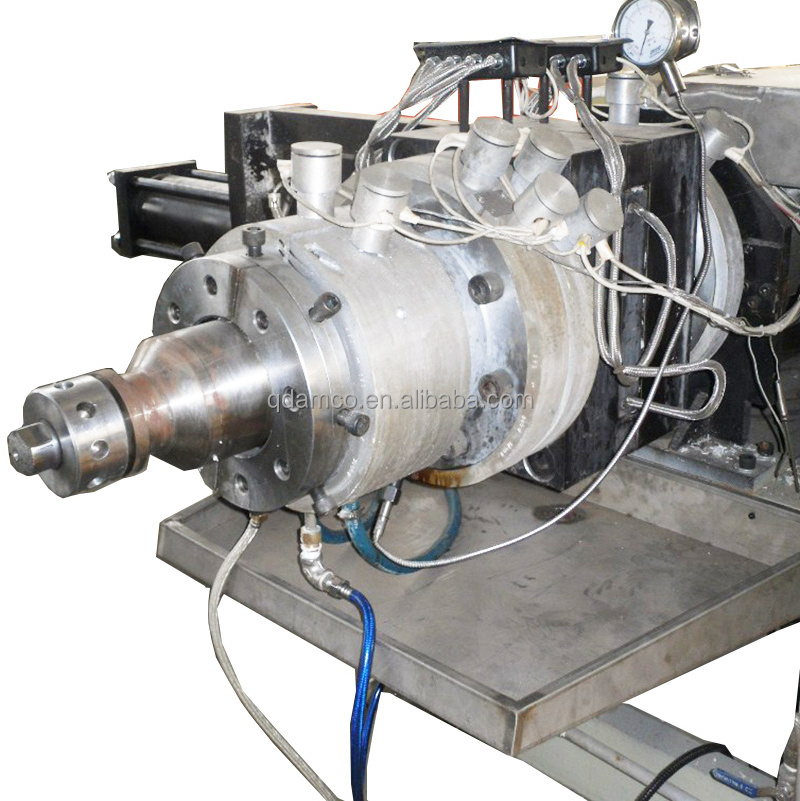

2. Equipment Features:

EPE foam clothe making machine use the latest technology, the product have high foaming ratio, low power consumption; the motor adopts explosion-proof machine, SIEMENS frequency inverter for stable speed regulation; Japan OMRON temperature controller for accuracy control, the whole production line is of convenient operation, automatic control, stable and reliable working.

3. Technical Parameters

|

Extruder model |

SM-EPE 90 |

SM-EPE105 |

SM-EPE120 |

SM-EPE150 |

SM-EPE170 |

|

Product width (mm) |

1000-1400 |

1000-1500 |

1000-2000 |

1000-2000 |

1000-2000 |

|

Product thickness (mm) |

0.5~4.5 |

0.5~6.5 |

0.8~8.0 |

1.0~12.0 |

2.0~16.0 |

|

Capacity (kg/h) |

80-110 |

100-150 |

180-250 |

350-400 |

420-500 |

|

Screw Dia and L/D Ratio |

90 55:1 |

105 55:1 |

120 55:1 |

150 55:1 |

170 55:1 |

|

Foaming agent |

Butane |

||||

|

Foamed ratio |

20-40 |

||||

MAIN MACHINES OF THE PRODUCTION LINE

VARIOUS PRODUCTS: