- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0

-

SiC Content (%):

-

90

-

Place of Origin:

-

Henan, China

-

Model Number:

-

GRD-SC5454

-

Brand Name:

-

GRD

-

Product name:

-

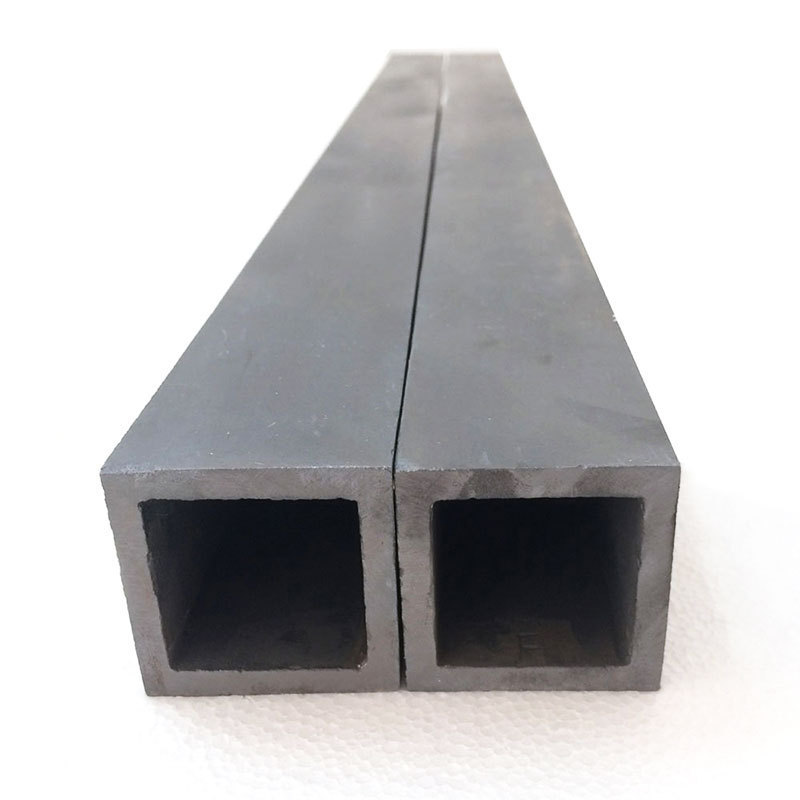

silicon carbide beam

-

Free Si:

-

10%

-

Raw material:

-

Silicon Carbide Powder

-

Color:

-

Black Grey

-

Bulk density:

-

3.02g/cm3

-

Max working temperature:

-

1380℃

-

Application:

-

Industrial Furnaces

-

Size:

-

Customized Size

-

Advantage:

-

Life Long

-

Feature:

-

Thermal Shock Resistance

Quick Details

-

SiO2 Content (%):

-

0.1

-

Al2O3 Content (%):

-

0.1

-

MgO Content (%):

-

0.01

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0

-

SiC Content (%):

-

90

-

Place of Origin:

-

Henan, China

-

Model Number:

-

GRD-SC5454

-

Brand Name:

-

GRD

-

Product name:

-

silicon carbide beam

-

Free Si:

-

10%

-

Raw material:

-

Silicon Carbide Powder

-

Color:

-

Black Grey

-

Bulk density:

-

3.02g/cm3

-

Max working temperature:

-

1380℃

-

Application:

-

Industrial Furnaces

-

Size:

-

Customized Size

-

Advantage:

-

Life Long

-

Feature:

-

Thermal Shock Resistance

Product Description

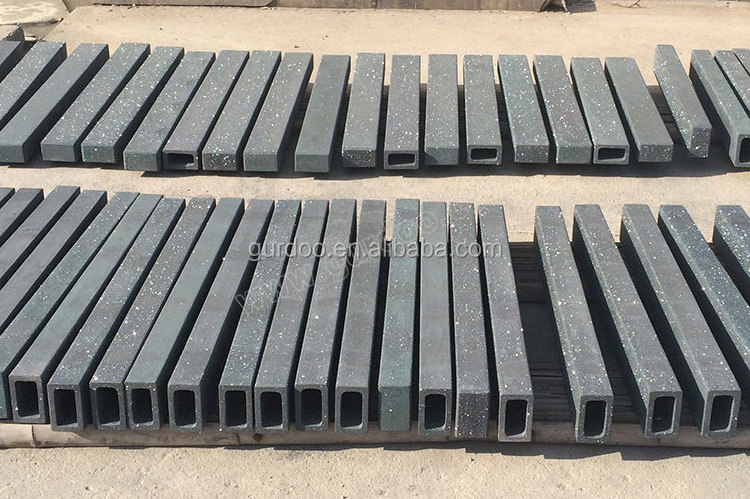

Reaction sintered sic kiln furniture silicon carbide beam sisic beams for refractory

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties, excellent thermal conductivity, low thermal expansion, and is resistant to corrosion from acids. Because of its excellent properties, silicon carbide products are more and more widely applied in various fields nowadays.

|

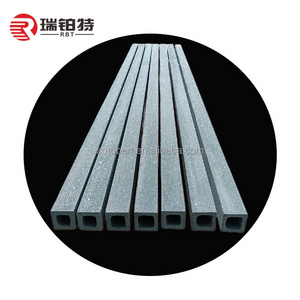

Types of silicon carbide beam

|

|

|

|

1. Recrystallized silicon carbide (RSIC)

--- max temperature 1650℃ |

10~150mm

|

|

|

2. Nitride bonded silicon carbide (NSIC)

--- max temperature 1450℃ |

2500mm

|

|

|

3. Reaction sintered silicon carbide (SiSiC / RBSiC)

--- max temperature 1380℃

|

|

|

|

4. Pressureless sintered silicon carbide (SSiC)

--- max temperature 1600℃ |

|

|

-

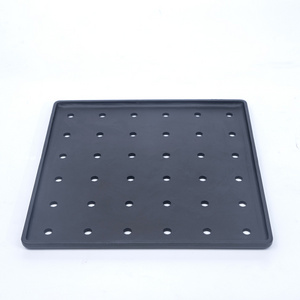

Application and use

Silicon carbide beam is widely used in ceramic high temperature kiln, steel mill quenching furnace, mine material classification cyclone, large boiler and power plant desulfurization and dust removal equipment, coal slag pneumatic conveying equipment and high-tech equipment. Applied in machinery, metallurgy, electronics, chemical industry, iron and steel, ceramics, paper making, mineral processing and so on.

Detailed Images

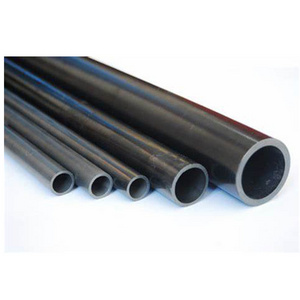

Silicon carbide products contain tube, beam, thermocouple protection sheath, riser pipe, roller, bushing, shield, burner nozzle, loading plate (shelf board), ignitor, crucible, sealing ring, wafer, rod, beads, ball and other irregular shapes.

Size Information

|

Silicon carbide beam

|

|

|

|

|

||||

|

Item

|

Unit

|

RSiC

|

NSiC

|

SiSiC

|

||||

|

Density

|

(g/cm3)

|

2.60-2.72

|

≥2.75

|

≥3.02

|

||||

|

Porosity

|

%

|

≤17

|

≤10

|

≤0.1

|

||||

|

Thermal Expansion

|

10-6 k-1

|

4.8

|

4.6

|

4.5

|

||||

|

Thermal conductivity

|

W/m.k

|

23

|

25

|

45

|

||||

|

Bending strength

(4-point)

|

MPa (at20℃)

MPa (1200℃)

|

≥ 90

≥100

|

≥150

≥170

|

≥250

≥280

|

||||

|

Youngs Modulus

|

GPa (20℃)

|

240

|

280

|

320

|

||||

|

Max temperature

|

℃

|

1650

|

1450

|

1380

|

||||

Related Products

Packing&Shipping

Silicon carbide beam is packed in export standard plywood case outside, lined with sponge and foam inside. It is also individually packed with buffer material to ensure the safety of the goods.

The goods will be shipped by air, by sea, by railway or by express delivery/courier like DHL, FedEx, TNT, UPS, EMS and so on.

Company Introduction

Henan Gurdoo Industry Co.,Ltd. is founded by engineers who have more than 20 years’ experience in research and production, which is specialized in manufacturing SiC heaters, MoSi2 heating elements, alumina ceramics, silicon carbide refractory, high temperature furnace and also can supply molybdenum and tungsten products, ceramic fiber insulation and quartz glass tube, etc.

Focusing on professional high temperature working field, we have the stable and efficient industrial production with ISO9001, CE, GB, CO, FTA certifications etc. All material & components adopt the qualified materials. 100% quality check and durable testing for every product before shipment will supply you high quality products and VIP service.

We have a well team-conscious, the ability of communication and coordination, work hard, meticulous and patience can afford the pressure of the work.

We provide cost efficient quality products for our customers, assisting them to gain competitive advantages are our major focus.

Focusing on professional high temperature working field, we have the stable and efficient industrial production with ISO9001, CE, GB, CO, FTA certifications etc. All material & components adopt the qualified materials. 100% quality check and durable testing for every product before shipment will supply you high quality products and VIP service.

We have a well team-conscious, the ability of communication and coordination, work hard, meticulous and patience can afford the pressure of the work.

We provide cost efficient quality products for our customers, assisting them to gain competitive advantages are our major focus.

After Sales Service

Our advantages

1. Any inquiries will be replied professionally within 24hours.

2. Technical staff available for the technical assistance anytime.

3. Professional customization of furnace and project is offered.

4. Small MOQ, Fast delivery and competitive freight.

5. Also can help to purchase other products if you needed.

2. Technical staff available for the technical assistance anytime.

3. Professional customization of furnace and project is offered.

4. Small MOQ, Fast delivery and competitive freight.

5. Also can help to purchase other products if you needed.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of silicon carbide beam, such as dimension or drawing, quantity, application etc.

Q2. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application. Then our technical staff will check and offer you the most suitable type or material.

Q3. How can we place an order?

You can contact any sale person by email, trade manager, Skype, WhatsApp, WeChat and so on.

And more details of the products you supplied will be helpful to get the targeted responses.

Q4. How long our order can be finished?

A mass of semi-finished products and standard sizes are available in stock, and 10-30days for bulk production or customized products.

Q5. What do you do on quality control?

Q6. How can we get the sample?

Free samples can be supplied after communication, but freight is for your account.

Q7. Can you accept OEM/ODM?

Yes, your goods will be produced exactly according to your drawings.

Please offer the specification of silicon carbide beam, such as dimension or drawing, quantity, application etc.

Q2. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application. Then our technical staff will check and offer you the most suitable type or material.

Q3. How can we place an order?

You can contact any sale person by email, trade manager, Skype, WhatsApp, WeChat and so on.

And more details of the products you supplied will be helpful to get the targeted responses.

Q4. How long our order can be finished?

A mass of semi-finished products and standard sizes are available in stock, and 10-30days for bulk production or customized products.

Q5. What do you do on quality control?

For every batch, each step and finished products will be inspected when producing by QC department.

Q6. How can we get the sample?

Free samples can be supplied after communication, but freight is for your account.

Q7. Can you accept OEM/ODM?

Yes, your goods will be produced exactly according to your drawings.

Let’s light up your business now!

Skype: zhdebbie426

Email: debbie@gurdoo.com

Website: www.gurdoo.com

Hot Searches