- Product Details

- {{item.text}}

Quick Details

-

Center Height (mm):

-

60 mm

-

Max.Transformer Capacity(kVA):

-

30 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UnionSpring

-

Weight (KG):

-

900

-

Dimension(L*W*H):

-

1750(L)x1250(W)x2000(H)

-

Wire Diameter Range (mm):

-

1 - 5 mm

-

Function:

-

Automatic CNC Winding Coil

-

Application:

-

Hollow Coil Winding Machine

-

Delivery time:

-

10-20 Days

-

Wire type:

-

Enameled Flat Copper Wire winding Equipment

-

Max. working lenght of wire feeder:

-

130MM

-

Wire feeding axis servo:

-

0.4kw

-

Winding axis servo:

-

2.0kw

-

Lifting axis servo:

-

2.0kw

-

Arm axis servo:

-

0.75kw*5

-

Winding Direction:

-

left and right

Quick Details

-

Max. Load (KG):

-

850 KG

-

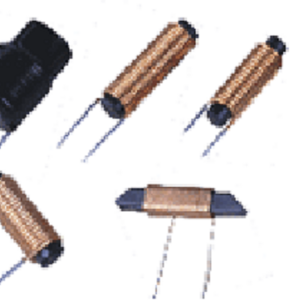

Coil Type:

-

hollow

-

Length of Axis (mm):

-

130 mm

-

Center Height (mm):

-

60 mm

-

Max.Transformer Capacity(kVA):

-

30 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UnionSpring

-

Weight (KG):

-

900

-

Dimension(L*W*H):

-

1750(L)x1250(W)x2000(H)

-

Wire Diameter Range (mm):

-

1 - 5 mm

-

Function:

-

Automatic CNC Winding Coil

-

Application:

-

Hollow Coil Winding Machine

-

Delivery time:

-

10-20 Days

-

Wire type:

-

Enameled Flat Copper Wire winding Equipment

-

Max. working lenght of wire feeder:

-

130MM

-

Wire feeding axis servo:

-

0.4kw

-

Winding axis servo:

-

2.0kw

-

Lifting axis servo:

-

2.0kw

-

Arm axis servo:

-

0.75kw*5

-

Winding Direction:

-

left and right

Products Description

|

Model No.

|

US-850

|

|

Wire diameter

|

T: 0.3-5.0mm

W: 3.0-15.0mm

W*T: 40mm

2

|

|

Max. working length of wire feeder

|

130mm

|

|

Winding direction

|

R/L direction

|

|

Wire feeding axis servo

|

0.4kw

|

|

Wire axis setting range

|

0.1⁰-2359.9⁰

|

|

Winding axis servo

|

2.0kw

|

|

Lifting axis setting range

|

0.1-40

|

|

Lifting axis servo

|

2.0kw

|

|

Dimension (L*W*H)

|

1750*1250*2000mm

|

|

Weight

|

900kg

|

US-850 CNC Winding Machines Features:

2. The machine adopts an independent wire feeding device, which can realize single-time, multiple wire feeding, and wire feeding of any length; the rotating core device is located behind the board surface, and the servo is controlled separately, which can realize 360⁰ rotation in positive and negative directions

3. The winding shaft is directly installed on the arm shaft, and there are 2 sets of servo synchronous control. It can realize

forward and reverse winding, dense winding and variable pitch winding, and can realize single-layer, multi-layer and simple

winding.

4. Imported servo, imported planetary reducer transmission, high operating accuracy

5. The machine adopts windows operation interface, which can save the adjustment parameters of products of various specifications.

3. The winding shaft is directly installed on the arm shaft, and there are 2 sets of servo synchronous control. It can realize

forward and reverse winding, dense winding and variable pitch winding, and can realize single-layer, multi-layer and simple

winding.

4. Imported servo, imported planetary reducer transmission, high operating accuracy

5. The machine adopts windows operation interface, which can save the adjustment parameters of products of various specifications.

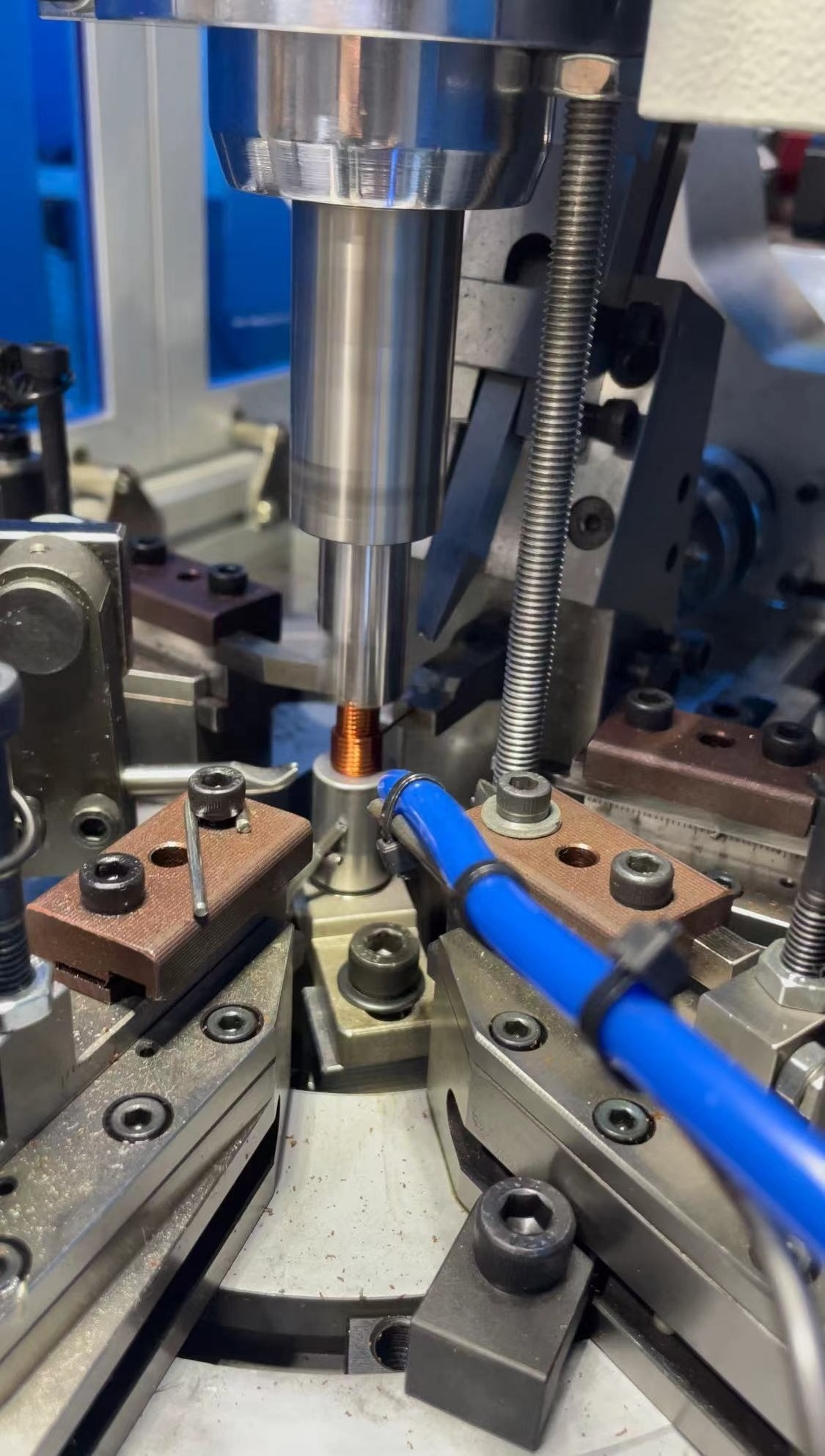

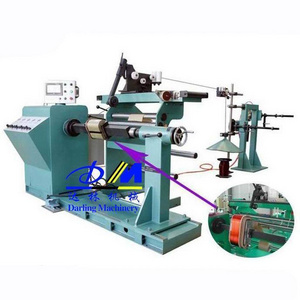

Details Images

Working Table

Wire Decoiler

Wire Feeding Wheels

Contriollor

Transformer

Sanyo Motor

Hot Searches