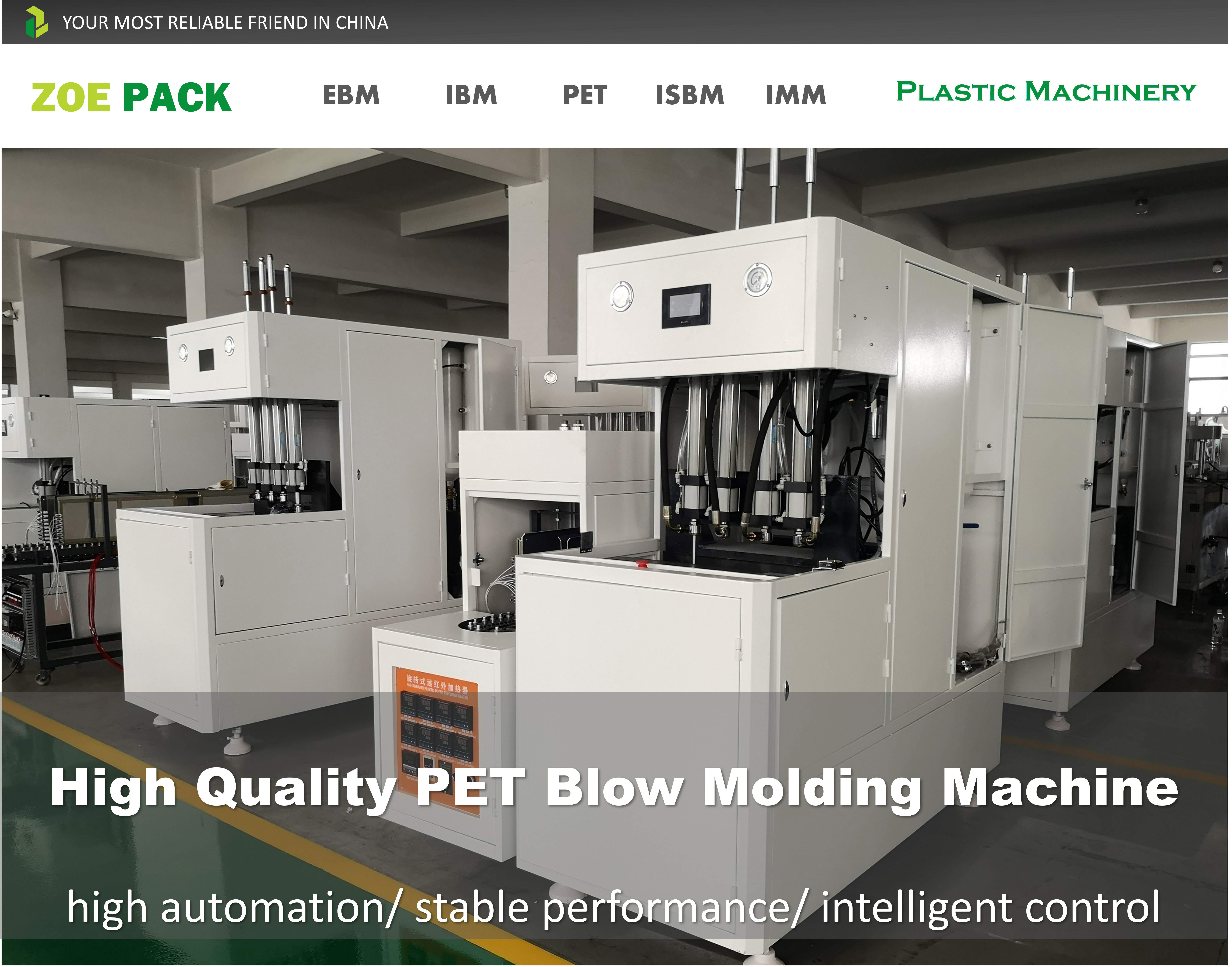

Semi-automatic bottle blowing machine is controlled by microcomputer,control the technical parameters more accurately.PET bottle blowing machine is simple and safe to operate.It only requires one person and does not require special training. PET blow molding

machine is suitable for blow molding of plastic packaging bottles such as carbonated beverage bottles, mineral water bottles, hot

filling bottles and cosmetic bottles. It is suitable for the production of small beverage

companies and daily chemical product companies.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

1000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Zoepack

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

4100*1600*1900

-

Power (kW):

-

43

-

Weight (KG):

-

3500 KG

-

Model Number:

-

ZP-2L-4

-

Light tube quantity:

-

32 pcs

-

Light tube power:

-

1.25 KW

-

Maximum heating power:

-

40 KW

-

All electric machine installition:

-

43 KW

-

Actual consumption:

-

30%-60%

-

Work pressure:

-

7-9kg/c㎡

-

Blow bottle pressure:

-

25-35kg/c㎡

-

Color:

-

Custom Color

-

Key words:

-

pet blowing machine plastic bottles making machine

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

100 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

1000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Zoepack

-

Year:

-

New

-

Voltage:

-

Acoording customer country

-

Dimension(L*W*H):

-

4100*1600*1900

-

Power (kW):

-

43

-

Weight (KG):

-

3500 KG

-

Model Number:

-

ZP-2L-4

-

Light tube quantity:

-

32 pcs

-

Light tube power:

-

1.25 KW

-

Maximum heating power:

-

40 KW

-

All electric machine installition:

-

43 KW

-

Actual consumption:

-

30%-60%

-

Work pressure:

-

7-9kg/c㎡

-

Blow bottle pressure:

-

25-35kg/c㎡

-

Color:

-

Custom Color

-

Key words:

-

pet blowing machine plastic bottles making machine

Production Description

ZOE PACK

Semi Automatic PET Bottle Blow Molding Machine

This PET bottle making blow moulding machine is controlled by microcomputer. The plastic

blowing machine can control the technical parameters more accurately.With the upper and lower system,emergency stop system,independent counter device,count the output accurately, with infrared lamp heating device,penetrating power, preform rotation heating, heating evenly and quickly.

PET semi-automatic plastic bottle blowing machine is suitable for blowing plastic PET bottles such as carbonated beverage bottles,mineral water bottles, cosmetic bottles and hot filling bottles etc.

Technical Parameters

|

Main machine (blower + oven )

|

Item

|

ZP-2L-4

|

|

Product Spec

|

Max. product volume (L/cav)

|

2L

|

|

|

Max. product neck size (mm)

|

100

|

|

|

Max. product diameter (mm)

|

180

|

|

|

Max. product height (mm)

|

300

|

|

|

Cavities

|

4

|

|

Blow molding part

|

Die force (KN)

|

100

|

|

|

Die stroke (mm)

|

270

|

|

|

390*345

|

|

|

|

Mould thickness

|

Adjustable

|

|

|

Mould spacing (mm)

|

Adjustable

|

|

|

Max. pulling stroke (mm)

|

400

|

|

|

Operation pressure (Mpa)

|

0.8-1.0

|

|

|

Operation air pressure consumption (1tr/min)

|

200

|

|

|

Blow pressure (Mpa)

|

1.2-2.8

|

|

|

Blow air pressure consumption (1tr/min)

|

300

|

|

|

Output (pcs/h)

|

2600-2800 (500ml bottle)

|

|

|

Machine size (LxWxH)(m)

|

1.46*0.58*1.8

|

|

|

Machine weight (KG)

|

650

|

|

Oven

|

Temperature grade (rate)

|

8

|

|

|

Heating time (S)

|

90-200

|

|

|

Voltage (V)

|

220 or as your rrquest

|

|

|

Frequency (HZ)

|

50/60

|

|

|

Total power (KW)

|

16

|

|

|

Oven Size (LxWxH)

|

1.35*0.55*1.15

|

|

|

Oven weight (KG)

|

300

|

Machine Advantages

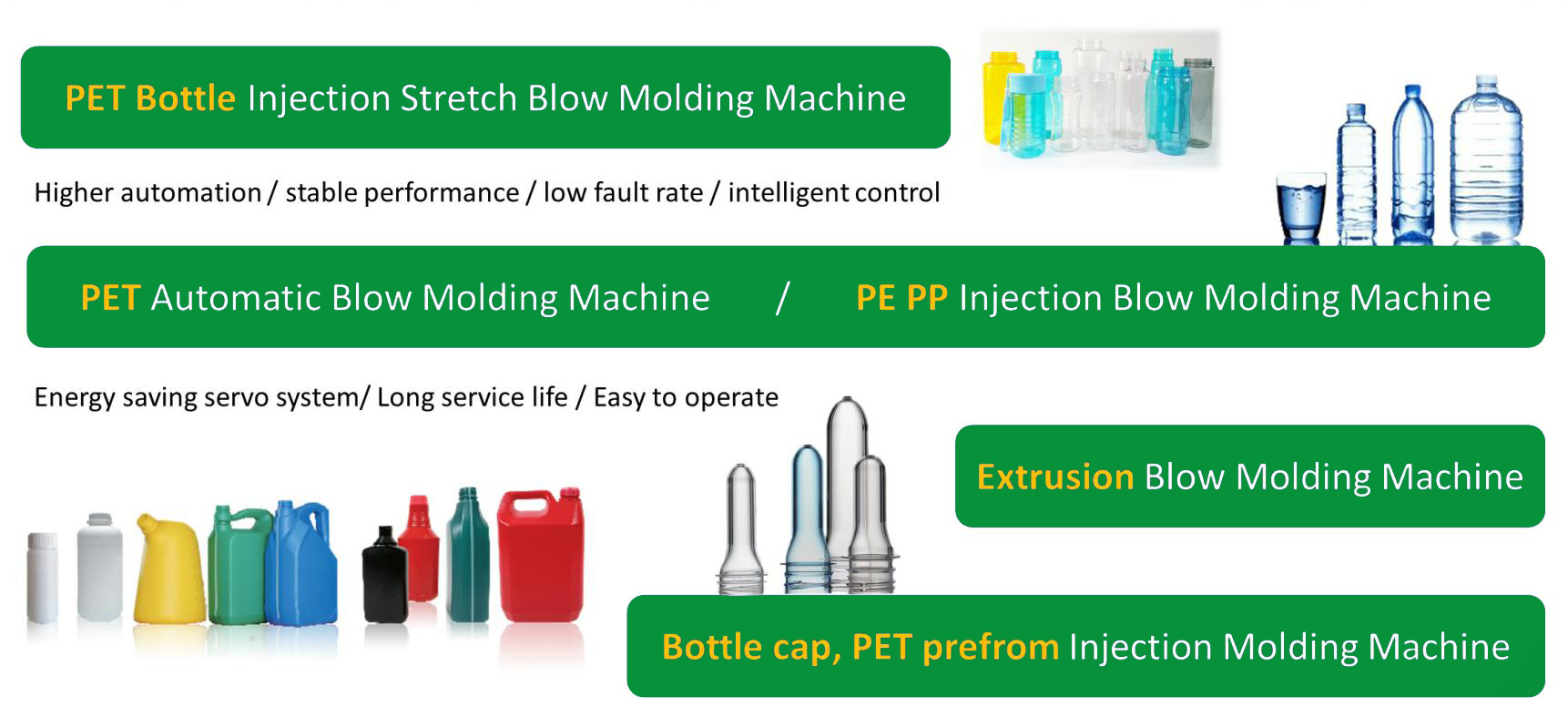

Q Series PET Bottle Blowing Machine Description

PET linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

PET linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

Infrared lamp heating

heating lamp,reflector width and height can be adjusted to suit preform heating of different structure,with automatic

temperature-removal device to ensure the constant temperature of oven.

Specially designed high rigidity composite mold structure

Specially designed high rigidity composite mold structure, wide applicability, suitable for various types of mold thickness, easy

to adjust and save energy, less air demand, precision polished spindle, equipped with photoelectric sensor, low noise,rapid

response, long working hours , stable performance,ensure stable operation.

Professional Workshop

Our Professional PET Blow Molding Machine Workshop...

Applications

Hot Searches