- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

none

-

Blade Width:

-

more

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIVTER

-

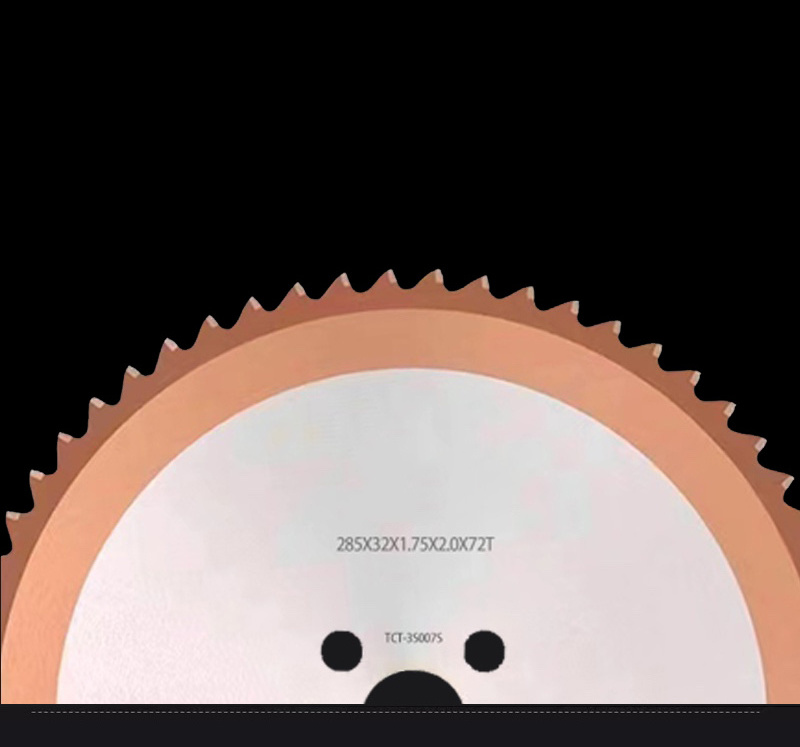

Model Number:

-

more

-

Name:

-

Panel saw blade

-

Material:

-

Carbide/High Quality Steel Disc

-

Applicable:

-

push table saw, panel saw

-

Function:

-

artificial single and double veneer

-

Features:

-

The incision surface is smooth and free of burrs

Quick Details

-

Blade Length:

-

Other

-

Finishing:

-

Other

-

Size:

-

more

-

Warranty:

-

none

-

Blade Width:

-

more

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIVTER

-

Model Number:

-

more

-

Name:

-

Panel saw blade

-

Material:

-

Carbide/High Quality Steel Disc

-

Applicable:

-

push table saw, panel saw

-

Function:

-

artificial single and double veneer

-

Features:

-

The incision surface is smooth and free of burrs

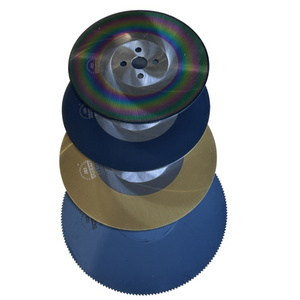

Recommend Products

Products Description

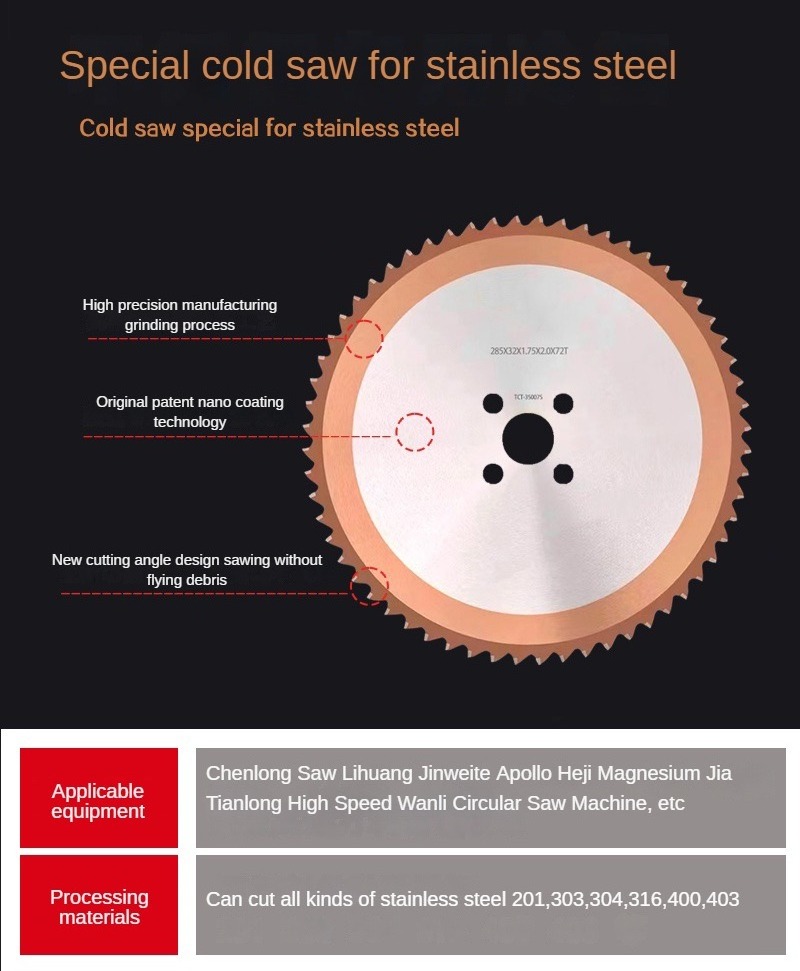

The cermet cold saw is a tool specially used for cold cutting processing of non-magnetic materials such as metals and ceramics. It has the advantages of high hardness, high strength, high wear resistance, high precision and environmental protection. It is widely used in aerospace, machinery manufacturing, electronics industry and other fields, especially in the processing of metal-ceramic composite materials, quartz crystals, glass and other materials. The performance is particularly outstanding in cutting processing.

The tool material of cermet cold saw is usually cermet composite material, which has the advantages of high hardness, high strength and high wear resistance. During the cutting process, the cutting edge of the cermet tool can remain sharp, reduce cutting resistance, and improve cutting efficiency and accuracy. At the same time, cermet cutting tools also have excellent wear resistance and high thermal stability, which can maintain stable performance in high-speed cutting and high-temperature environments and extend the service life of the cutting tools.

The cutting method of cermet cold saw is to physically remove the material through the tool to achieve the cutting process of the material. This cold cutting process does not generate cutting heat, avoids thermal damage and deformation of the material, and maintains the original physical properties and accuracy of the material. At the same time, cermet cold saws also have smaller chip sizes and less cutting pollution, which is beneficial to environmental protection and improvement of production efficiency.

When using a cermet cold saw, you need to pay attention to the installation and use of the tool to ensure the stability and reliability of the tool. At the same time, it is also necessary to select appropriate tool materials and shapes according to different material properties and processing needs to achieve the best cutting effect and efficiency. In addition, you also need to pay attention to the maintenance and care of the cutting tools to keep them sharp and clean to avoid damage and failure of the cutting tools.

In general, the cermet cold saw is a professional cutting tool with high performance, high precision, high stability and environmental protection. It is suitable for cold cutting processing of non-magnetic materials such as metals and ceramics. Its application can improve production efficiency, reduce material waste, ensure product quality, and promote the advancement and upgrading of industrial production technology.

|

Name

|

diamond saw blade

|

|

Application

|

cut aluminum, cut iron

|

|

Size

|

can be customized

|

Contact Us

1. who are we?

We are based in Fujian, China, start from 2016,sell to Domestic Market(60.00%),Southeast Asia(5.00%),Central America(5.00%),North

America(5.00%),South Asia(4.00%),Northern Europe(4.00%),Africa(3.00%),Mid East(3.00%),Oceania(2.00%),Southern

Europe(2.00%),Eastern Asia(2.00%),Eastern Europe(2.00%),Western Europe(2.00%),South America(1.00%). There are total about 11-50

people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

wood-working machine,circular saw blade,Bi-metal band saw blade,wood-working tools,metal-working machine

4. why should you buy from us not from other suppliers?

Xiamen Strongtech Co., Ltd is a professional enterprise specialized in R&D ,manufacturing and sales . We focus on wood-working

machine, machines for cutting pipes and bending pipes,wood-working tools,band saw blade,since 2000.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Russian

Hot Searches