Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage

tank by slurry pump.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

600*200*100mm, 600*300*100mm, etc

-

Processing:

-

Block cutting machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shende

-

Voltage:

-

As Per Local Condition

-

Dimension(L*W*H):

-

Cutter: 17.5*2.8*2.9m

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

22000 kg

-

Product Name:

-

automatic ACC block machine machinery making AAC brick in Mongolia

-

Name:

-

aac brick

-

Keywords:

-

brick making machinery

-

Block Type:

-

Aerated Autoclaved Concrete lightweight block

-

Raw material:

-

Sand (or fly ash), lime, gypsum, aluminum powder

-

Green cake size:

-

4.2m, 4.8m, 6m

-

Products:

-

block & panel

-

Cutting method:

-

Step fixed & step mobile type

-

Annual capacity:

-

20,000-300,000m3/year

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Sand (or fly ash), lime, gypsum, aluminum powder

-

Production Capacity (Pieces/8 hours):

-

50,000-300,000m3/year

-

Brick size:

-

600*200*100mm, 600*300*100mm, etc

-

Processing:

-

Block cutting machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shende

-

Voltage:

-

As Per Local Condition

-

Dimension(L*W*H):

-

Cutter: 17.5*2.8*2.9m

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

22000 kg

-

Product Name:

-

automatic ACC block machine machinery making AAC brick in Mongolia

-

Name:

-

aac brick

-

Keywords:

-

brick making machinery

-

Block Type:

-

Aerated Autoclaved Concrete lightweight block

-

Raw material:

-

Sand (or fly ash), lime, gypsum, aluminum powder

-

Green cake size:

-

4.2m, 4.8m, 6m

-

Products:

-

block & panel

-

Cutting method:

-

Step fixed & step mobile type

-

Annual capacity:

-

20,000-300,000m3/year

20000m3-300000m3 German technology hebel automatic ACC manufacturing plant block machine machinery making AAC brick in Mongolia

INTRODUCTION

Introduction:

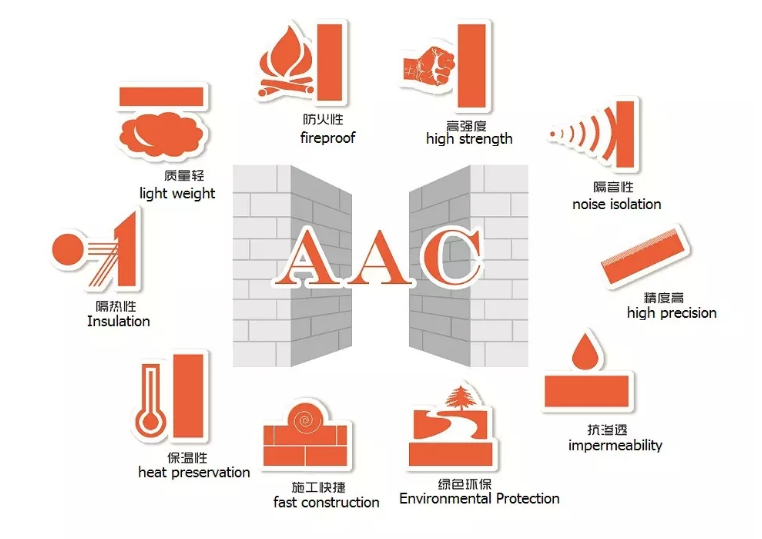

AAC is a kind of light cellular silicate products.

Main material based on

Silicon materials

(sand, fly ash, gangue contains

silicon) and Calcium(cement and lime), mix with foaming agent (Aluminium powder), after batching, mixing,

pouring, pre-curing, cutting, steam (autoclaved), and other process, finally, get this light weight concrete products.

pouring, pre-curing, cutting, steam (autoclaved), and other process, finally, get this light weight concrete products.

Classification:

AAC Classification: in general, it can be classified according to the types of raw materials, manufacture process and functions. Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels.

Advantage:

AAC is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption,unprecedented build ability and superior ecological green features. In China, AAC is one of the light wall materials which was popularized and applied at the earliest and the most widely.

PRODUCT DESCRIPTION

Process flow of AAC production line:

1. Raw materials processing

2. Batching, mixing and casting

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump

then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

3. Curing

After slurry pouring into the mould, put the mould box into the curing room with 50~70℃. After 2-3 hours curing,the blocks become

solid.

solid.

4.

Cutting

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting

machine,vertical cutting ,two sides cutting,and remove the top waste material.

machine,vertical cutting ,two sides cutting,and remove the top waste material.

5. Steaming

Finished cutting using semi-product crane carry to the front of autoclavegrouped,hoisting machine or dragger will drag steam

trolley into autoclave to steam,it need 10-12 hours.

trolley into autoclave to steam,it need 10-12 hours.

6.

Finished block dealing

Finished product out of autoclave,with separting machine to separate layer by layer.

7.

Packing

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift

transport the finished products to piled yard according to specifications to stack.

transport the finished products to piled yard according to specifications to stack.

Raw material proportion of AAC production line:

--> Fly ash type:

|

Name

|

Unit

|

Proportion

|

|

Fly ash

|

%

|

65-70

|

|

Cement

|

%

|

6-15

|

|

Lime

|

%

|

18-25

|

|

Gypsum

|

%

|

3-5

|

|

Aluminum powder paste (600kg/m³)

|

1/10000

|

8

|

|

Water & material rate

|

|

0.60-0.65

|

|

Curing temperature

|

℃

|

36-40

|

|

Aluminum mixing time

|

S

|

30-40

|

|

Name

|

Unit

|

Proportion

|

|

Sand

|

%

|

55-65

|

|

Cement

|

%

|

10-20

|

|

Lime

|

%

|

20-30

|

|

Gypsum

|

%

|

2-3

|

|

Aluminum powder paste (600kg/m³)

|

1/10000

|

8

|

|

Water & material rate

|

|

0.65-0.75

|

|

Curing temperature

|

℃

|

35-38

|

|

Aluminum mixing time

|

S

|

30-40

|

SAMPLE PLANT

20000m3-300000m3 German technology hebel automatic ACC manufacturing plant block machine machinery making AAC brick in Mongolia

PACKAGING AND DELIVERY

1. General AAC block plant equipment transport with 40 HQ container.

2. Ball mill transport with 40 OT or 40 FR according the size.

3. Autoclave transport on deck of ship.

4. Cutting machine usually transport with 40 FR or on deck of ship.

2. Ball mill transport with 40 OT or 40 FR according the size.

3. Autoclave transport on deck of ship.

4. Cutting machine usually transport with 40 FR or on deck of ship.

COMPANY PROFILE

Shende Company,

with

20 years manufacturing experience in

AAC industry,

sells AAC plant all over the world such as

Indonesia,

Vietnam,

Mongolia, Haskstein,

Iraq, Saudi Arabic, Kuwait, some other Mid-east countries,

and so on.

Excellent after-sales service gives you no worries!

1. We own advanced technicians and ensure supply of enough accessories.

2. We have perfect management and regular tour visit to our customers.

3. The Technical Service Development makes regular tour check and training upon customers.

4. We have training system to rise up customer's technique.

5. We promise one year warranty time for quality.

2. We have perfect management and regular tour visit to our customers.

3. The Technical Service Development makes regular tour check and training upon customers.

4. We have training system to rise up customer's technique.

5. We promise one year warranty time for quality.

FAQ

Q1: Can l visit your factory?

A1: Yes. We warmly welcome you to visit our factory through video or on site.

Q2: Can you test our material or block samples?

A2: Yes. We can test it and provide you analysis report.

Q3: Do you provide whole AAC production line flow chart?

A3: Yes. Our experienced engineers are specialized in designing process flow for various project.

A3: Yes. Our experienced engineers are specialized in designing process flow for various project.

Q4. How about price?

A4: As a factory manufacturer, we can quote you the lowest price. For saving time and absolutely honest business attitude, we quote as low as possible for any customer, and discount can be given according to quantity.

A4: As a factory manufacturer, we can quote you the lowest price. For saving time and absolutely honest business attitude, we quote as low as possible for any customer, and discount can be given according to quantity.

Q5: How long is the warranty of the AAC production line?

A5: One year generally.

A5: One year generally.

Q6: Do you provide equipment operation training?

A6: Yes. We can send professional engineers to the working site for installation, adjustment, and operation training.

A6: Yes. We can send professional engineers to the working site for installation, adjustment, and operation training.

CERTIFICATIONS

Hot Searches