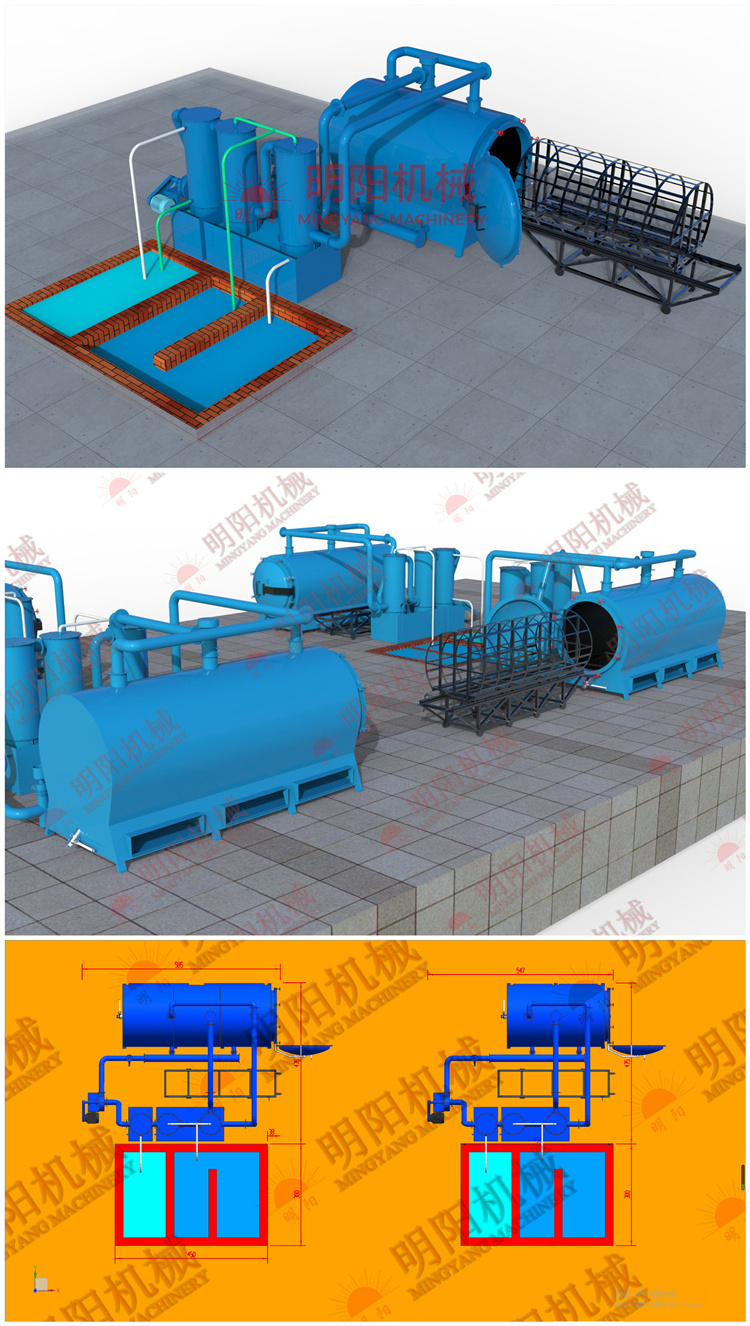

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3.5x 2.0 x 2.2m

-

Voltage:

-

380V

-

Power:

-

0kw

-

Weight (KG):

-

4500

-

Name:

-

Horizontal Air Flow Carbonization Furnace

-

Capacity:

-

800-1000kg/day

-

Carbonization time:

-

810 Hours

-

Cooling Time:

-

8-10 Hours

-

Raw material:

-

wood logs,biomass sawdust briquette,branches,coconut shell etc

-

Product name:

-

continuous charcoal making machine carbonization stove

-

Feature:

-

high carbonizing efficiency

-

Temperatur degree:

-

400-600

-

Advantage:

-

Energy Saving

-

Usage:

-

Charcoal Maker

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Effective Volume:

-

9CBM

-

Dimension(L*W*H):

-

3.5x 2.0 x 2.2m

-

Voltage:

-

380V

-

Power:

-

0kw

-

Weight (KG):

-

4500

-

Name:

-

Horizontal Air Flow Carbonization Furnace

-

Capacity:

-

800-1000kg/day

-

Carbonization time:

-

810 Hours

-

Cooling Time:

-

8-10 Hours

-

Raw material:

-

wood logs,biomass sawdust briquette,branches,coconut shell etc

-

Product name:

-

continuous charcoal making machine carbonization stove

-

Feature:

-

high carbonizing efficiency

-

Temperatur degree:

-

400-600

-

Advantage:

-

Energy Saving

-

Usage:

-

Charcoal Maker

Product Application:

It adopts the advanced carbonized technology heat flow, carbonized rate increased significantly, The carbonized rate is 99%.And

the operation is very convenient, good safety, high production efficiency, can save a lot of energy, good environmental protection

performance.

|

Model

|

WTH150

|

|

|

|

|||

|

Volume

|

9CBM

|

|

|

|

|||

|

Inner pot size

|

1.5*3.5m

|

|

|

|

|||

|

Inner pot steel thickness

|

10mm Boiler steel

|

|

|

|

|||

|

Raw material

|

Wood log ,wood briquettes, jute stick

|

|

|

|

|||

|

Capacity

|

800-1000kg output charcoal per day

|

|

|

|

|||

|

Machine size

|

3.5x 2.0 x 2.2m

|

|

|

|

|||

Clients feedback:

The whole line of making wood briquette charcoal

1.Crush the raw material into small pieces (diameter is about 3-5mm);

2.Dry the material by machine or dried it in the sun , till the moisture is less than 12%;

3.Put the material into feed let of briquette machine;

4.Produce the briquette stick from biomass material without any additive;

5.Carbonized the briquette stick.

1.Wood crusher:

2.Sawdust dryer:

3.Briquette machine:

4.Carbonization stove:

Raw Materials: Sawdust, Crops Straw(corn stalk, beanstalk, broomcorn stalk, cotton stalk, rape stalk,palm kernel shell, groundnut stem, sunflower stalk), Husk, Grass, Bush branches, Bamboo butt, Bamboo scraps, Bagasse and so on.

Charcoal carbonization furnace is the ideal equipment for wood briquettes to have anoxic distillation carbonization. The final products charcoal briquette bars can be used for heating furnace, industrial boilers, biomass power plant,barbecue and so on.

Hoist type wood carbonization stove:

Wood sawdust charcoal making machine:

Square charcoal making machine

Gongyi Xiaoyi Mingyang Machinery plant is located in Zhengzhou.Henan province.

Our machinery plant is specialize in WOOD BRIQUETTE MACHINE 38 years.

There have production line of makingwood charcoal briquette(including crusher , dryer , wood briquette machine, carbonization stove) ,

production line of making wood pellet (including crusher, dryer , wood pellets machine , dust separation plant and packaging machine)

production line of making coal ball briquette(includingvertical crusher, mixing machine, coal briquette pressing machine and dryer machine for coal briquette)

and other equipment such as screw conveyor, belt conveyor, scrap conveyor , sawdust carbonization stove, floating fish feed machine and so on.

Our machines have the best quality and we have got many certification such as CE, ISO, BV.

ave got many certification such as CE, ISO, BV.