Match the extruder according to the size of the corrugated pipe and the required output.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

30000X1450X2800mm

-

Power (kW):

-

37

-

Weight:

-

4500 KG

-

Name:

-

Plastic pipe extruder

-

Raw material:

-

Plastic granules

-

Output (kg/h):

-

200kg/h

-

Motor brand:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINA

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

30000X1450X2800mm

-

Power (kW):

-

37

-

Weight:

-

4500 KG

-

Name:

-

Plastic pipe extruder

-

Raw material:

-

Plastic granules

-

Output (kg/h):

-

200kg/h

-

Motor brand:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

Product Description

Features

The fully automatic plastic double wall corrugated drain pipe extrusion making machine uses HDPE / PP as raw materials. The inner wall of the double wall corrugated pipe produced by this production line is very smooth and flat. And the outer wall is trapezoidal corrugated shape. This kind of double wall corrugated pipe has the characteristics of good corrosion resistance, high insulation, small flow resistance etc. as the ordinary plastic pipe, but also because of special inner and outer wall hollow ring structure, it has the advantages of high rigidity, light weight, high pressure resistance, good toughness, abrasion resistance,impact resistance, not easy damage, convenient construction, low installation cost, long service life etc. The double wall corrugated pipe is generally connected by the expansion socket and the sealing ring. This can effectively prevent the impact of thermal expansion and contraction. The double wall corrugated pipe is widely used in the fields of highway, railway roadbed,subway engineering, waste landfill, tunnel, green belt, sports field and high water content caused by the slope protection and other drainage areas.

|

MODEL

|

SJ-50

|

SJ-65

|

SJ-65

|

SJ-90

|

SJ-120

|

|

Speed of Screw Rotationl

|

20-90

|

20-120

|

20-120

|

20-120

|

20-120

|

|

Pipe Range(mm)

|

8-32

|

16-75

|

110-200

|

110-280

|

315-400

|

|

Power (kw)

|

15-22

|

22-55

|

55-75

|

90-110

|

160-200

|

|

Speed(m/min)

|

8-15

|

10-25

|

8-15

|

5-12

|

5-8

|

|

L/D Ratio

|

30

|

30

|

33

|

33

|

33

|

Detailed Images

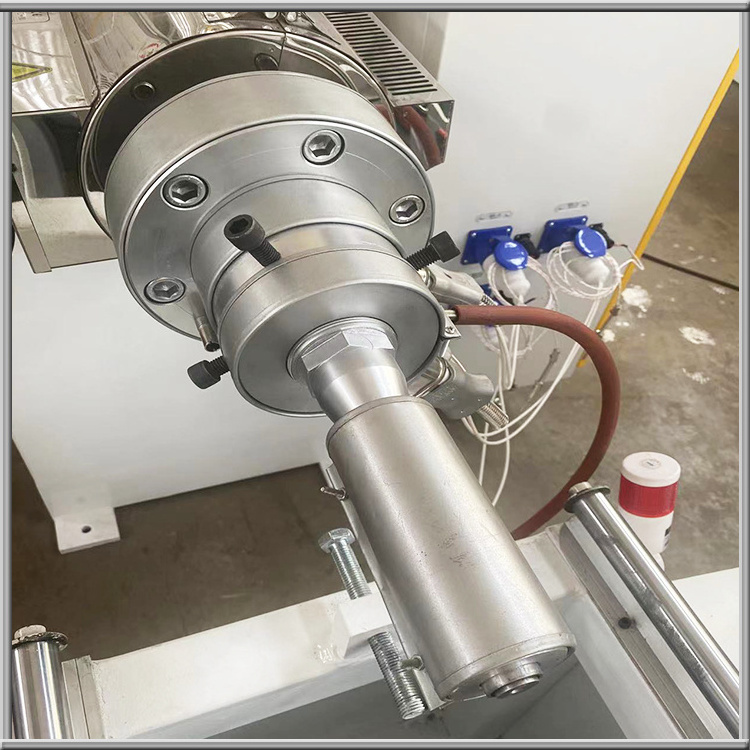

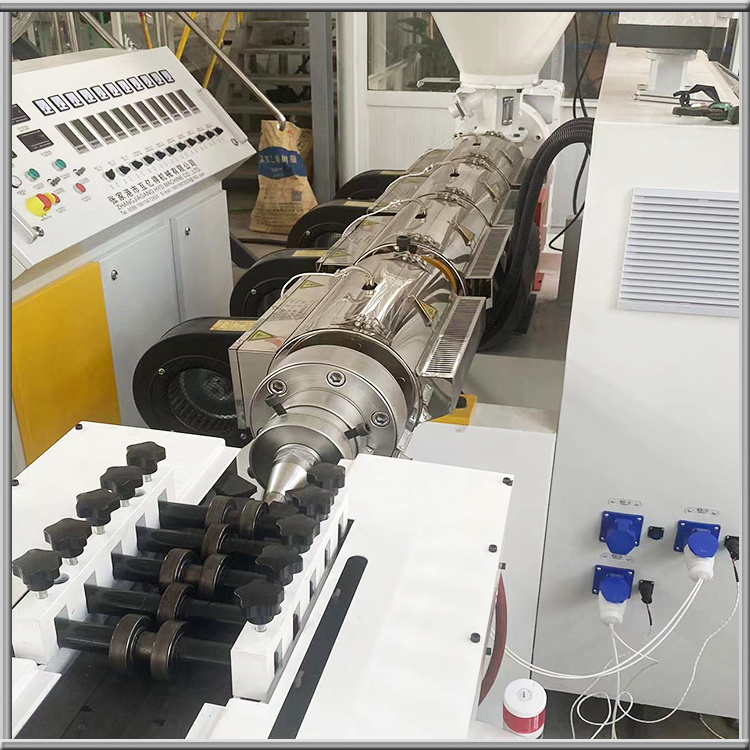

Extruder

.

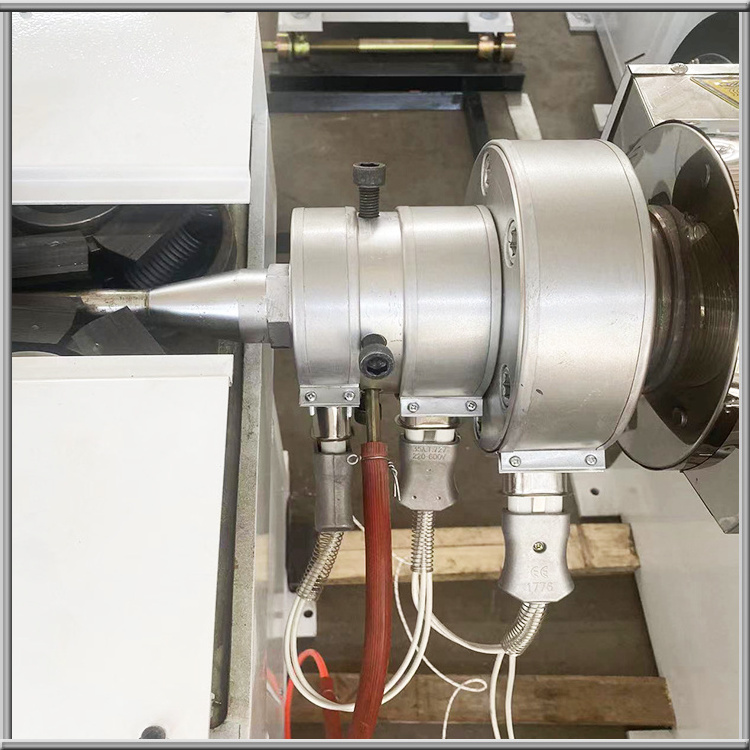

Mould

.

Precision processing and high-temperature rust prevention treatment.

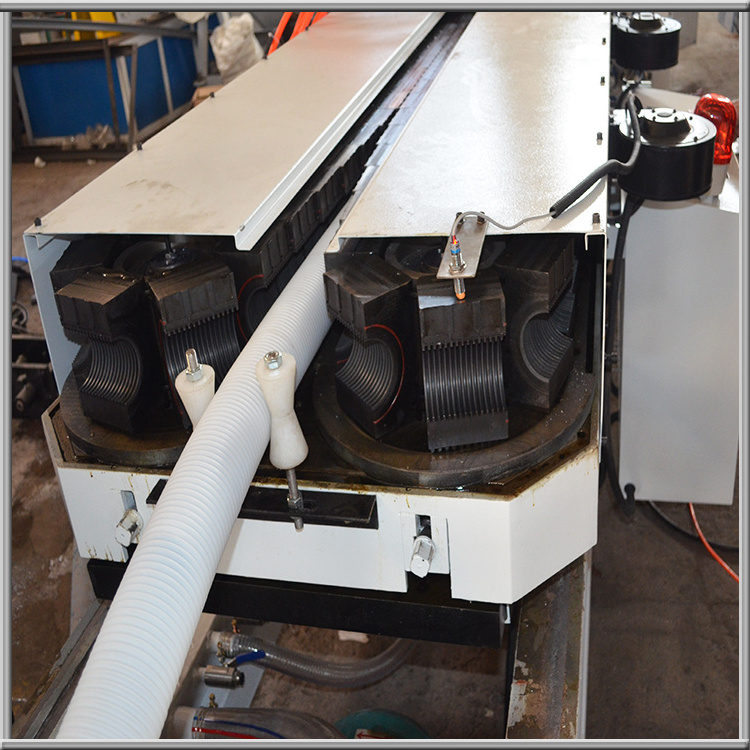

Forming machine

.

Used for shaping and regulating the speed of corrugated pipes.

Forming module

.

According to the pipe diameter, it is divided into ordinary and high-speed.

Winding speed control device

.

Automatically control the speed of the winding machine, with a gravity sensing device. The gravity drops and the winding speed is accelerated. The gravity is balanced and the winding speed is stable.

Pipe winding machine

.

Automatic winding, automatic unloading, automatic meter counting, automatic speed regulation.

Dual station winding machine, time-saving and labor-saving.

Screw barrel :

38CrMoAlA material, after nitriding and diffraction treatment, with a nitriding layer depth of ≥ 0.6mm, has sufficient strength, wear resistance, and corrosion resistance.

Barrier type screw, asymmetric slotted barrel design.

Gearbox :

Strong thrust bearing, high torque output; The gears are made of special alloys with hard tooth surfaces and processed by grinding technology. They are high-quality, high torque, and high-speed gearboxes, with low heat generation, low noise, and long service life.

Heater :

Fast heating, uniform heat dissipation, beautiful appearance, good insulation performance, and durability, suitable for high temperature and high power requirements.

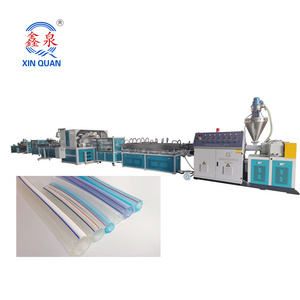

Final product

Can be made of materials such as PVC, PE, PP, HDPE, etc., with single wall and double wall structures, and can be made of any pipe diameter size.

Hot Searches