Crimp function has detachable installation function

Faster processing speed for corner processing and arc bending

Multiple angle forming and cutting

More convenient debugging

Simpler forming

Convenient operation

Powerful function

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

800

-

Product name:

-

Spring Making Machine CNC Coil Machine

-

Model:

-

BH-8322

-

Wire diameter:

-

0.2-2.5mm

-

Max Outer Diameter of coiled spring:

-

Max dia 60mm

-

Max Wire feed speed:

-

0-110m/min

-

Cam Rotation speed:

-

1-100RPM

-

Wire Feed Servo Motor:

-

2.7KW

-

Core switching servo motor:

-

0.75KW

-

Cam servo motor:

-

2.7KW

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LILER

-

Voltage:

-

380V/415V/220V/Customized

-

Weight (KG):

-

800

-

Product name:

-

Spring Making Machine CNC Coil Machine

-

Model:

-

BH-8322

-

Wire diameter:

-

0.2-2.5mm

-

Max Outer Diameter of coiled spring:

-

Max dia 60mm

-

Max Wire feed speed:

-

0-110m/min

-

Cam Rotation speed:

-

1-100RPM

-

Wire Feed Servo Motor:

-

2.7KW

-

Core switching servo motor:

-

0.75KW

-

Cam servo motor:

-

2.7KW

Product Overview

Spring Making Machine CNC Coil Machine

I . To use of imported computer control system and imported servo motor.

II. The computer is English interface, easy to operation, accurate positioning, the computer can control three to eight servo

motors, all can be synchronized or run separately.

III. The product has a precision detection tracking device, it can automatically shut down if find a substandard product.

V. The mechanical automatic lubricating oil supply design, to ensure the equipment movement for a long time

VII. When it has wireless, broken, wrapped wire, automatic shutdown design and wire frame automatic function to make production

more easily and efficiently.

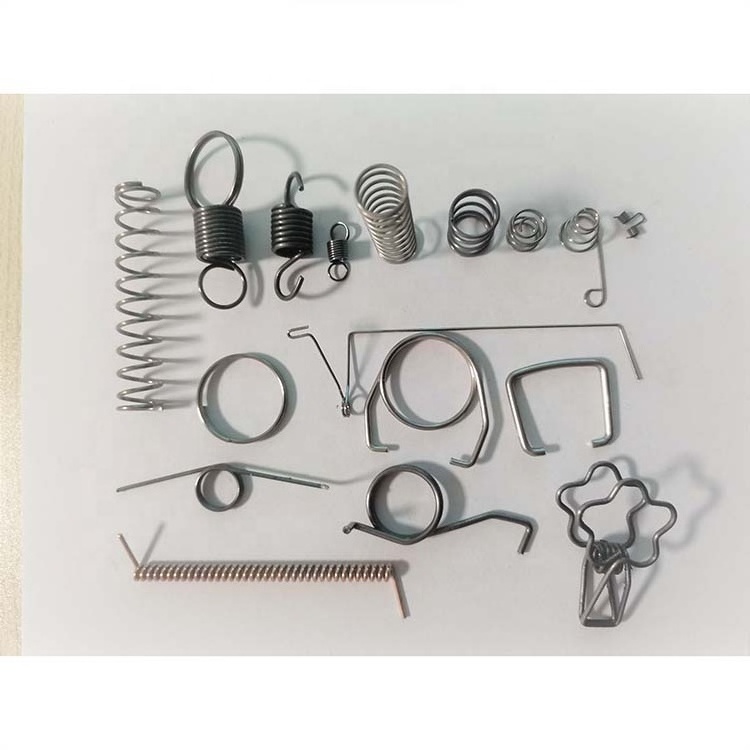

VIII. The product applicable to the production of compressed spring, pagoda spring, coil spring, wave spring and others.

II. The computer is English interface, easy to operation, accurate positioning, the computer can control three to eight servo

motors, all can be synchronized or run separately.

III. The product has a precision detection tracking device, it can automatically shut down if find a substandard product.

V. The mechanical automatic lubricating oil supply design, to ensure the equipment movement for a long time

VII. When it has wireless, broken, wrapped wire, automatic shutdown design and wire frame automatic function to make production

more easily and efficiently.

VIII. The product applicable to the production of compressed spring, pagoda spring, coil spring, wave spring and others.

FEATURES AT A GLANCE

1.A precious inspection tracer device is installed, it will stop working automatically When the unqualified product is found.

2.The parameters such as major diameter, angle etc can be modified at any time according to the working status displayed on the fluorescence screen.

3.It is suitable for producing double torsion spring, straight spring, pagoda- -shaped compression spring, rectangle spring,swirl spring and other different spring and special-shaped spring etc.

Machine concentrated have unique increase stroke, specially processed complex shape of the spring unique tuner-core structure, never relaxed, no maintenance, unique integrated feed line structure, Japan servo motor and Taiwan CNC control system ensure the accuracy of the wire feed to meet the demanding requirements, production good quality spring.

1.Characteristics: timing, disconnection, (starved feeding), abnormal stops (deviation), automatic alarm stop run, induction

2.control, high safety control compatibility, can use for parallel or serial electric production machinery, to independent or

3.synchronization feeding material.Automatic material feed frame BH-150

-350-500-1000(weight bearing between 150-1000 Kg)

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

||

|

1

|

Item No

|

BH-8322

|

|

|

||

|

2

|

Wire diameter of coiled material

|

φ0.2-φ2.5mm(Iron wire φ0.5-3.5mm)

|

|

|

||

|

3

|

Max outer diameter of coiled spring

|

Max dia 60mm

|

|

|

||

|

4

|

Wre feed instruction value

|

±0.01-±9999.99

|

|

|

||

|

5

|

Max wire feed speed

|

0-110m/min

|

|

|

||

|

6

|

Cam instruction value

|

±0.1°-±359.9°

|

|

|

||

|

7

|

Wire feed servo power

|

2.7KW

|

|

|

||

|

8

|

Core-switching servo motor

|

0.75KW

|

|

|

||

|

9

|

Cam servo motor

|

2.7KW

|

|

|

||

|

10

|

Power supply

|

380V/415V/220V/customized

|

|

|

||

|

11

|

Machine size

|

1500x900x1900mm

|

|

|

||

|

12

|

Machine weight

|

800KGS

|

|

|

||

Varied Material Application

FAQ

1.Do you have after sale service ?

Sure , we provide after sale service.If there any question video, phone, on site guide is okay.

2. How about shapes machine to do?

We can customzied the shape as you need, and arrange the blade as your inquiry

3. How about the warrenty ?

1 year warrenty period, if any question about machine beforing working, contact for free spare parts and operation guide.

4. How to ensure customs' rights ?

We provide trade assurance on Alibaba and custom service 24 online to provide help.

5. How to shipment?

We have professional operators can arrange customs clearance. Professional fowraders arrange ship. can export from tianjin port,

Qingdao Port, Shanghai Port, yiwu port, etc. as you need.

Hot Searches