Charcoal carbonization furnace includes four parts mainly:

One whole set machine = one outer stove+ three inner containers+ purification system+hoist.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ainuok

-

Voltage:

-

Custom

-

Power:

-

3.5kw

-

Diameter:

-

1900*2

-

Capacity:

-

800kg per hour

-

three inner containers:

-

3

-

Wood Carbonized Time:

-

For Wood(>15%):8-10 hours

-

Briquette Carbonized Time:

-

For briquettes: 6-8 hours

-

Feeding Capacity(Kg/batch:

-

4.5-6.3T per day

-

Weight:

-

2.6T, 2.6T

-

Dimension:

-

2.1*2.3*1.9m

-

Diameter of inside:

-

1.2m

-

Local Service Location:

-

Indonesia

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

Quick Details

-

Place of Origin:

-

China

-

Marketing Type:

-

Hot Carbonization Furnace

-

Core Components:

-

carbonization chamber

-

Brand Name:

-

Ainuok

-

Voltage:

-

Custom

-

Power:

-

3.5kw

-

Diameter:

-

1900*2

-

Capacity:

-

800kg per hour

-

three inner containers:

-

3

-

Wood Carbonized Time:

-

For Wood(>15%):8-10 hours

-

Briquette Carbonized Time:

-

For briquettes: 6-8 hours

-

Feeding Capacity(Kg/batch:

-

4.5-6.3T per day

-

Weight:

-

2.6T, 2.6T

-

Dimension:

-

2.1*2.3*1.9m

-

Diameter of inside:

-

1.2m

-

Local Service Location:

-

Indonesia

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

Product Description

Charcoal carbonization furnace is an ideal equipment for making high quality charcoal. It is widely suitable for large range of raw materials.Such as wood log,wood branches,wood chips,sawdust briquette,rice husk /hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse etc.After carbonization, the raw material will become final charcoal.

Composition

Daily capacity of one set of furnace

2-3T/24hrs for dry wood with moisture less than 8% or wood briquette(usually 2.5-3tons raw materials can get 1 ton final charcoal)

Note : different moisture of the raw materials, the daily productivity will be different & try to make sure the wood log to be similar size, or the carbonize effect will be effected & make sure moisture no more than 50%.

Note : different moisture of the raw materials, the daily productivity will be different & try to make sure the wood log to be similar size, or the carbonize effect will be effected & make sure moisture no more than 50%.

Working Process

Main Features : continuous carbonization +Smoke recycle burning + Self Purification

A) Fill one inner container full with wood log or briquette.,then moist fulfilled inter container into the outer stove for carbonization.Put on cover of outer stove,add fuel into the heating part and light them for preheating until temperature reach about 400 degrees(there is a temperature indicator on the machine ) .

B) during carbonization process, the inside charcoal briquette will produce flammable air,this air will run a cycle automatically for burning again, then it continuously do this circulation process,so there is no pollution at all during the whole process and smokeless.

C) after 8-10 hours,the inner container was carbonized totally. Use the hoisting equipment to hoist the inner container out for natural cooling, meanwhile, hoist another inner container into the outer stove for carbonization. So three inner containers will work continuously 24 hours with no waste of time.

Preheating Fuel Consumption

20-30 kg firewood or 15 kg liquefied gas per time

Carbonization Time

Wood logs ( 10--12hours,depends on the moisture of wood log,less moieture,less time), wood briquettes (8-10hours), coconut shell

(6hours)

About Cooling

after carbonization, put inner container outside for cooling naturally, the longer cooling time the better for charcoal quality

Application of Final Charcoal

1.Can be used for BBQ, boiler heating, family heating.

2.To make active carbon and other industrial usage.

2.To make active carbon and other industrial usage.

Advantage of carbonization furnace

1.Best carbonization effect and shortest carbonization time.

2.High carbonization rate, no smoking, little pollution, high efficiency.

3.Dry distillation, the carbonization temperature can be controlled and adjusted, the highest temperature can reach 800-1000 °C.

4.Can work continuously 24 hours without stopping.

5.It can collect wood tar oil and exhaust gas which can be recycled.

2.High carbonization rate, no smoking, little pollution, high efficiency.

3.Dry distillation, the carbonization temperature can be controlled and adjusted, the highest temperature can reach 800-1000 °C.

4.Can work continuously 24 hours without stopping.

5.It can collect wood tar oil and exhaust gas which can be recycled.

Specification

Carbonization furnace parameter

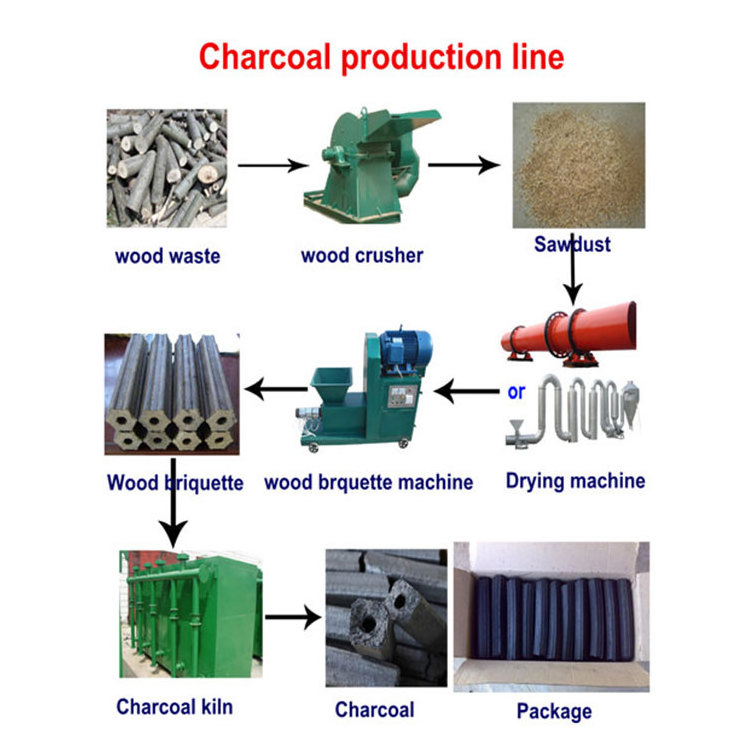

Full Process Line

Carbonization Furnace Factory

Before-sale services

1. Full time on line and in-time reply to your inquiries.

2. Recommend most suitable machines and line according to customer’s requirement.

3.Introduce details of the machine with pictures or video for your good acknowledgement.

2. Recommend most suitable machines and line according to customer’s requirement.

3.Introduce details of the machine with pictures or video for your good acknowledgement.

Sales service

1. Customized machine according to your request.

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

After-sales service

1. Offer the professional engineer assist you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality warranty for one year. Free repair for quality problem during one year.Spare parts only charge cost price after

warranty.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality warranty for one year. Free repair for quality problem during one year.Spare parts only charge cost price after

warranty.

More products,more details,welcome to contact us

1. Wood Crusher, Wood Hammer Mill, Branch Shredder/ Chipper, Wood Chipper, Chaffe Cutter, Grass Chopping Machine. 2. Animal Feed Pellet Machine/Mill, Aquatic Floating Fish Feed extruder, Wood Pellet Machine.

3. Baler Packing machine(Round,/Square Hay Baler)

4. Oil Presser

5. Honeycomb Charcoal/ Coal Briquette Machine.

3. Baler Packing machine(Round,/Square Hay Baler)

4. Oil Presser

5. Honeycomb Charcoal/ Coal Briquette Machine.

Hot Searches