- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Under voltage protection:

-

have

-

Maximum melting temperature:

-

3000℃

-

Working current:

-

500A

-

Arc melting cathode device:

-

The arc striking method is high-frequency arc striking

-

control accuracy:

-

+/-1-5 ℃ (above 600 ℃)

-

Inflatable gas type:

-

Helium and argon gas

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

RSE

-

Model Number:

-

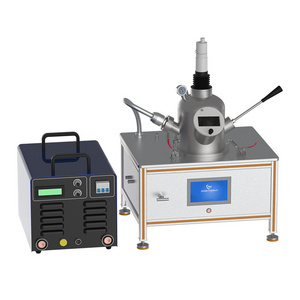

RSE- VAF-300

-

Place of Origin:

-

Guangdong, China

-

Under voltage protection:

-

have

-

Maximum melting temperature:

-

3000℃

-

Working current:

-

500A

-

Arc melting cathode device:

-

The arc striking method is high-frequency arc striking

-

control accuracy:

-

+/-1-5 ℃ (above 600 ℃)

-

Inflatable gas type:

-

Helium and argon gas

PRODUCT DESCRIPTION

SPECIFICATION

|

Product model

|

VAF-300

|

|

|

|

|||

|

|

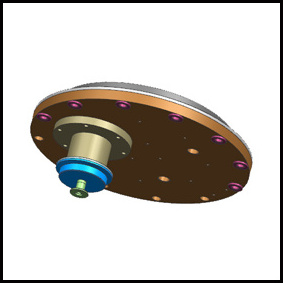

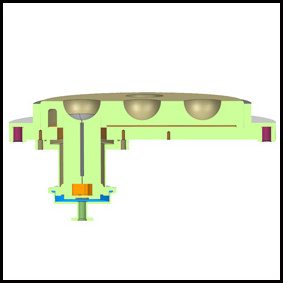

The water-cooled copper crucible has 5 stations (other stations can also be customized)

Each workstation is a hemispherical pot with a radius of 25mm (other sizes can also be customized)

One of the workstations is equipped with a suction casting device at the bottom

|

|

|

|

|||

|

|

Vacuum suction casting device, capable of casting metal rods with a diameter of 5mm and a length of 65mm By extracting air from the copper mold, molten metal can quickly enter the mold, resulting in metal rods with smaller shrinkage holes

|

|

|

|

|||

|

Maximum melting temperature

|

3000℃

|

|

|

|

|||

|

|

1. There is an observation window installed in the front, and LED lighting is installed in the rear of the cavity for easy observation of the arc initiation and melting status 2. The vacuum chamber, copper crucible, and arc starting electrode are all cooled by water cooling method

3. The up and down movement adopts a steering wheel design, and the operating joystick rotates flexibly

4. In order to ensure that the alloy ingot is flipped and melted multiple times without damaging the gas protective atmosphere, a mechanical arm flipping mechanism is used in the melting furnace

5. The crucible has a small size and a large quantity, making it convenient to make multiple samples while avoiding mutual contamination between samples 6. Install a suction casting device at the bottom, which can cast metal rods with a diameter of 5mm

|

|

|

|

|||

|

|

The size of the water-cooled vacuum chamber is Dia300X340

There is a door with a diameter of 200mm on the vacuum chamber, which

facilitates sample delivery and sampling There is an observation window with a diameter of 80mm on the furnace door, which is convenient for observing the arc melting state Install a robotic arm on the right side of the cavity for easy flipping of alloy ingots |

|

|

|

|||

|

Working current

|

500A

|

|

|

|

|||

|

Arc melting cathode device

|

The arc striking method is manual lifting with high-frequency arc striking

|

|

|

|

|||

|

Vacuum degree of cavity (molecular pump unit) (Scheme 1)

|

< 5X10 -4Pa

|

|

|

|

|||

|

Vacuum degree of cavity (diffusion pump unit) (Scheme 2)

|

< 5X10 -3Pa

|

|

|

|

|||

|

Type of gas that can be filled into the cavity

|

Helium and argon gas

|

|

|

|

|||

|

Gas filling is required during operation

|

High purity Ar gas (5N) or 5% H2+95% Ar is required during the metal melting process

|

|

|

|

|||

|

Maximum melting temperature

|

3000 C (can melt various refractory metals)

|

|

|

|

|||

|

Boost rate

|

<4Pa/h

|

|

|

|

|||

|

Tungsten electrode

|

Tungsten electrode with a diameter of 10mm (arc gun can be cooled by water), non consumable tungsten arc needle

The angle and distance between the electrode and the sample can be adjusted (maximum adjustment distance is 80mm)

The maximum temperature can reach 3000 ℃

|

|

|

|

|||

|

Undervoltage protection (water pressure)

|

Have

|

|

|

|

|||

|

control accuracy

|

+/-1-5 ℃ (above 600 ℃)

|

|

|

|

|||

|

Is the vacuum chamber water-cooled

|

yes+/-5℃

|

|

|

|

|||

|

Chiller (optional)

|

CW-6100AH

|

|

|

|

|||

|

Unit input voltage

|

380V /220V

|

|

|

|

|||

|

corrugated pipe

|

KF40X1000

|

|

|

|

|||

|

Vacuum baffle valve

|

KF40

|

|

|

|

|||

|

Front stage mechanical pump FX-32

|

power

|

1.2KW

|

|

|

|||

|

|

Voltage

|

380V

|

|

|

|||

|

|

speed

|

1450rpm

|

|

|

|||

|

|

Inlet Diameter

|

KF40

|

|

|

|||

|

|

Front pump pumping rate (L/S)

|

8

|

|

|

|||

|

|

Ultimate pressure

|

4X10 -2Pa

|

|

|

|||

|

|

caliber

|

DN100

|

|

|

|||

|

|

Scope of use

|

1×105Pa~1.3×10-4Pa (fluorine rubber ring seal)

1×105Pa~1.3×10-6Pa (Bellows seal)

|

|

|

|||

|

|

Valve leakage rate (Pa.L/s)

|

1.3×10-5Pa (fluorine rubber ring seal)

1.3×10-7Pa (Bellows Seal)

|

|

|

|||

|

Composite vacuum gauge

|

Power Supply

|

220V 50Hz 45W

|

|

|

|||

|

|

control accuracy

|

±1%

|

|

|

|||

|

|

measuring range

|

10-5 -10 5 Pa

|

|

|

|||

|

|

Molecular pump pumping rate L/S (for air)

|

300

|

|

|

|||

|

|

Molecular pump ultimate pressure (Pa)

|

5×10-7

|

|

|

|||

|

|

Cooling method

|

Water cooling

|

|

|

|||

|

|

Cooling water pressure (MPa)

|

0.1-0.2

|

|

|

|||

|

|

Cooling water temperature

|

<25℃< p="">

|

|

|

|||

|

Water-cooled machine (Optional)

|

Power Supply

|

220V 1.75Kw

|

|

|

|||

|

|

Maximum head

|

20-37m

|

|

|

|||

|

|

Rated flow rate

|

6-35L/min

|

|

|

|||

|

|

Water tank capacity

|

22L

|

|

|

|||

|

|

Refrigeration capacity

|

5.5KW

|

|

|

|||

|

|

Inlet and outlet

|

Rp1/2’’

|

|

|

|||

|

|

Overall dimensions

|

526*645*1100mm

|

|

|

|||

Vacuum suction casting device

Vacuum suction casting device, capable of casting metal rods with a diameter of 5mm and a length of 65mm

By extracting air from the copper mold, the molten metal can quickly enter the copper mold, resulting in metal rods with smaller shrinkage holes

Cavity door

Observation window

Lighting LED lights

Mechanical arm

Title goes here.

FAQ

Q. Are you a manufacturer or a trading company?

A. We are professional laboratory instrument manufacturers, have their own design team and factory, have mature technical experience, and can guarantee the quality of products and the optimal price.

Q. Our country's power supply and plug are different. How do you solve it?

A. We can supply a transformer and plug according to your local requirements according to the power plug of different countries.

Q. How long is your delivery time? If I want to customize the instrument, how long does it take?

A.1. lf the goods are in stock, it is 5-10 days. 2. We can provide customized services for our customers. It usually takes 30-60 days depending on the specifications of the custom instrument.

Q. How to pay?

A.T/T, LIC, D/P, etc., it is recommended to use Alibaba Trade Guarantee.

Q.How is the package of goods? Delivery methods?

A.1. Standard export fumigation sign wooden box packaging

2. Express, air, sea shipping according to customer requirements, find the most suitable way.also accept LC at sight.

Hot Searches