- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

180*176*185cm

-

Weight:

-

1000KGS

-

Name:

-

paper bag printing machine

-

Max.Printing Width:

-

1400 mm

-

Max.Material width:

-

1430 mm

-

Max.Printing Speed:

-

120 m/min

-

Paper Thickness:

-

30-350 gsm

-

Overprint Precision:

-

±0.15 mm

-

Thickness of Plate:

-

1.7 mm

-

After-sale Service:

-

engineers for overseas service;field installation and maintenance

-

Printing Color:

-

4 Color

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE, paper bag printing machine

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lilin Bag Printing Machine

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

180*176*185cm

-

Weight:

-

1000KGS

-

Name:

-

paper bag printing machine

-

Max.Printing Width:

-

1400 mm

-

Max.Material width:

-

1430 mm

-

Max.Printing Speed:

-

120 m/min

-

Paper Thickness:

-

30-350 gsm

-

Overprint Precision:

-

±0.15 mm

-

Thickness of Plate:

-

1.7 mm

-

After-sale Service:

-

engineers for overseas service;field installation and maintenance

-

Printing Color:

-

4 Color

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE, paper bag printing machine

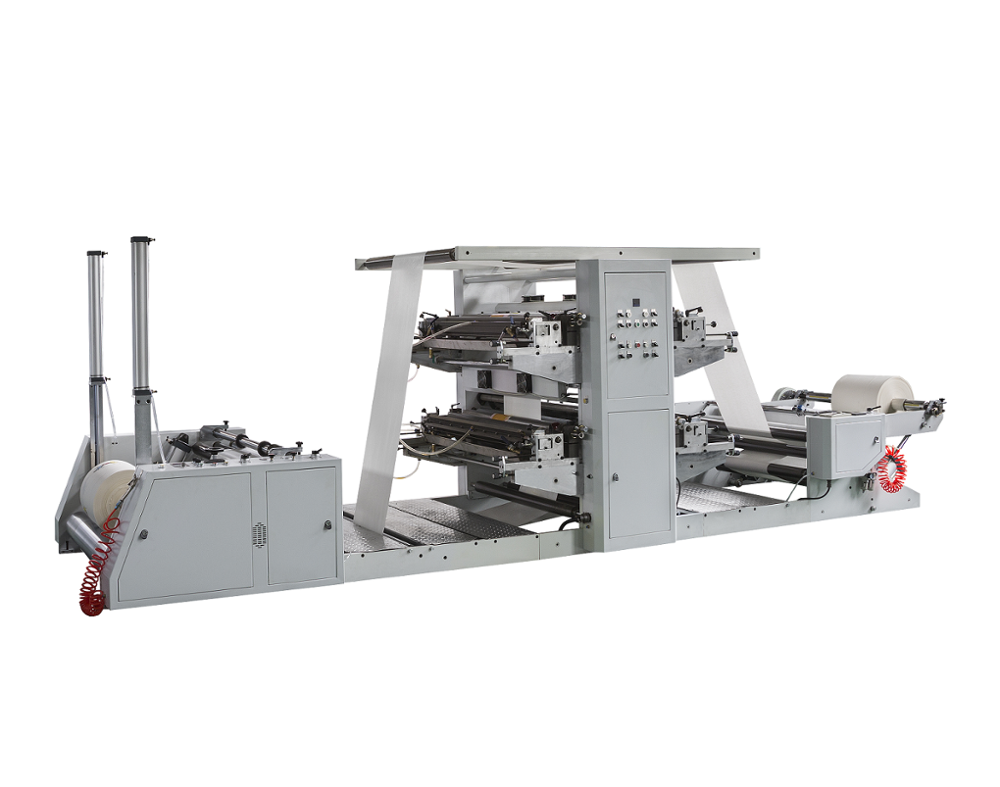

Paper Bag Printing Machine

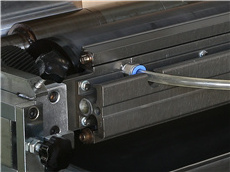

LST-41400 Flexible letterpress printing unit

Features:

1.paper bag printing machine adopts hard tooth surface gear helical gears, smooth operation, low noise, high accuracy and long life.

2.ink-ring sealed scraping knife scraping.

3.ink Ceramic Anilox roller, high speed dot rate, screen printed layered, stronger.

4.button-360 ° continuous and adjustable longitudinal register device.

5.pneumatic automatic printing plate roller.

6.the independent group automatic ink system, can be opened one or more sets of ink.

7.automatic lubricating oil system

Contact:

Website - www.lilinmachinery.com

Email- Lilin3 at lilinmachinery.com

Trade Manager - cn1525656379jutb

Office Phone:+86 577 65023567

Mr. Yao

Cellphone/Wechat: +86 13735586219

Specifications:

| Type | LST-41400 |

| Printing Color | 4 Color |

| Max.Printing Width | 1100 mm |

| Max.Material width | 1130 mm |

| Printing Length | 160-800 mm |

| Max.Printing Speed | 120 m/min |

| Paper Thickness | 30-350 gsm |

| Overprint Precision | ±0.15 mm |

| Thickness of Plate | 1.7 mm |

| Total Power | 8.5 kw |

| Overall Dimension | 180*176*185cm |

Configuration:

|

1.

paper bag printing machine adopts helical gears driven much stable running ,can reduce the gears gap moving to cause the printing effective ,High Harden Gears ,Increase the long life of gears ,reduce the gears using time ,ensure long time use and constant precision |

|

|

2.

With ink closed type ink doctor blade and ensure machine not flying ink in high speed ,so can be circle using ink and keep even of ink color when it is printing |

|

|

3.

Adopt 120mm larger diameter ceramic anilox roller to driven ink ,big diameter moving ink touch big area ,moving ink much stable ,ceramic anilox roller high precision ,and can be high precision for printing effective and clear pictures in details ;Ceramic dot detail, clear ink, high speed dot rate, screen printed layered, stronger |

|

|

4.

Button type 360 ° continuous and adjustable longitudinal register device, equipped with high speed than a right angle gear motor, registration easier and more simple, 360 ° vertical position alignment, any location easy to get the touch of a button |

|

|

5.

Pneumatic automatic printing plate roller, the machine stops printing plate roller off automatically, to avoid ink drying and material adhesion, when started printing plate roller will automatically reset |

|

|

6. Independent ink circulation system to ensure that the ink cartridge always has enough ink supply, ink viscosity always consistent. Avoid the ink cartridges do not have enough ink and ink drying lead to loss of print. |

|

|

7.

Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. The motor doesn’t need to work often so its power consumption is reduced and its life is extended. (User can choose single photoelectric sensor to control edge.) |

|

|

8.

automatic constant tension control system. The tension will be just right from beginning to end. |

|

|

9.

Pneumatic paper reel lifting device make paper reel changing easy. Press one switch and the paper reel will be lifted automatically. Avoid the personal injury. The pneumatic lifting system can make sure the stability of paper web feeding and avoid moving the feeding stand. |

|

|

10.

Automatic lubrication system can supply automatically the lubrication oil to every part which needs to be lubricated. The lubricating time and oil quantity can be set by user. Avoid damage of machine because user forgets to lubricate. The maintenance becomes easy! |

Our Services:

| 1. Installation and operation training; on-the spot teaching; instruction manual and video |

| 2. Field installation,field maintenance and repair service |

| 2. One year warranty; life-long maintenance |

| 3. Engineers available for overseas service all year round |

| 4. Quick-response on-line support; some models of our machines are monitorable via internet |

Delivery and Warranty:

|

DELIVERY PERIOD |

Approximately 45 days from the date of receipt of deposit , subject to reconfirmation or change when order is acknowledged. |

|

LOADING PORT |

Ningbo, Shanghai |

|

PAYMENT TERMS |

T/T, L/C, trade assurance, western union, cash, etc. |

|

INSTALLATION |

All bag making machines have been finished all adjustment in our workshop, installation personnel is not needed. If buyer needs our engineer to install the machine in site, t he charge ( VISA, accommodation, food, round air-tickets and salary 50USD /day) shall be paid by the buyer in case . |

|

TEST MATERIALS |

The buyer should prepare an adequate supply of test materials; our company does not have responsibility for undertak ing any testing of materials and costs. |

|

ELECTRICAL EQUIPMENT |

Unless other noted, the machine needs electric of 380V, 3 Phase, 50/60 Hz. Consult factory for special electrical requirements. |

|

WARRANTY |

T he factory guarantee that we supply new (unused) paper bag forming machines, and we offer warranty of 12 month. In this period, we will supply free parts which are broken because of quality. W e don ’ t offer warranty for wrong operation (including changing software of PC & HMI). |

FAQ:

| 1. Q: Are you trading company or manufacturer ? | A: We are manufacturer with our own factory and workers. |

| 2. Q: How long has your factory been in this field ? |

A: As one of the leading paper bag machinery manufacturers in China, we have more than 12 years of

experience of designing and producing paper bag machines. |

| 3. Q: Where is your factory ? How can I visit it? | A: Our factory is located in Ruian City (Wenzhou), Zhejiang Province, China. The nearest airport is Wenzhou Airport, 40-minutes' flight from Shanghai Pudong Airport (or 4 hours by train). |

| 4. Q: Samples available ? How can I get them ? | A: Sample bags or handles are available, but freight need to be paid by our customers. |

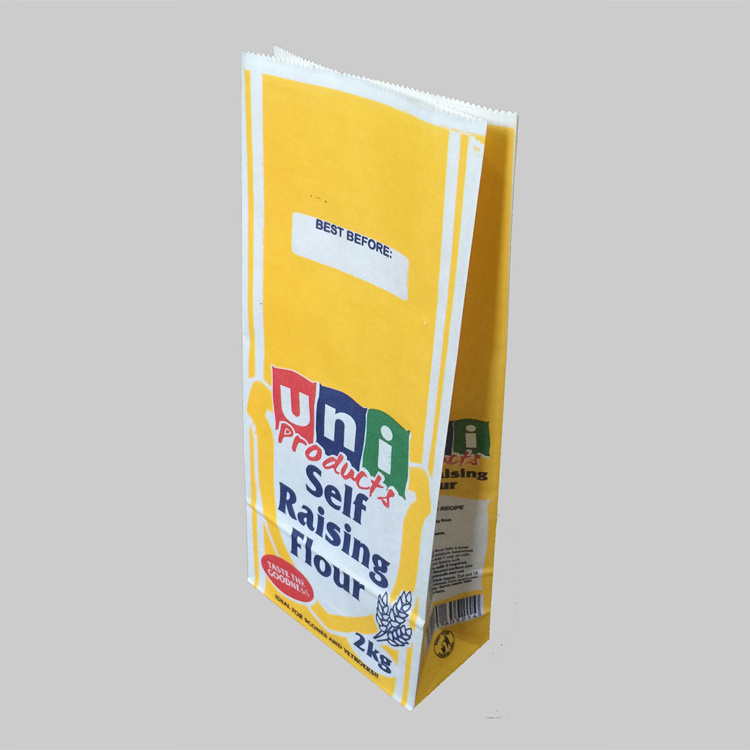

Samples of the paper bag printing machine:

Factory of Lilin paper bag printing machine :