- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YUHANG

-

Dimension(L*W*H):

-

500*450*1650mm

-

Weight:

-

40 KG

-

Product name:

-

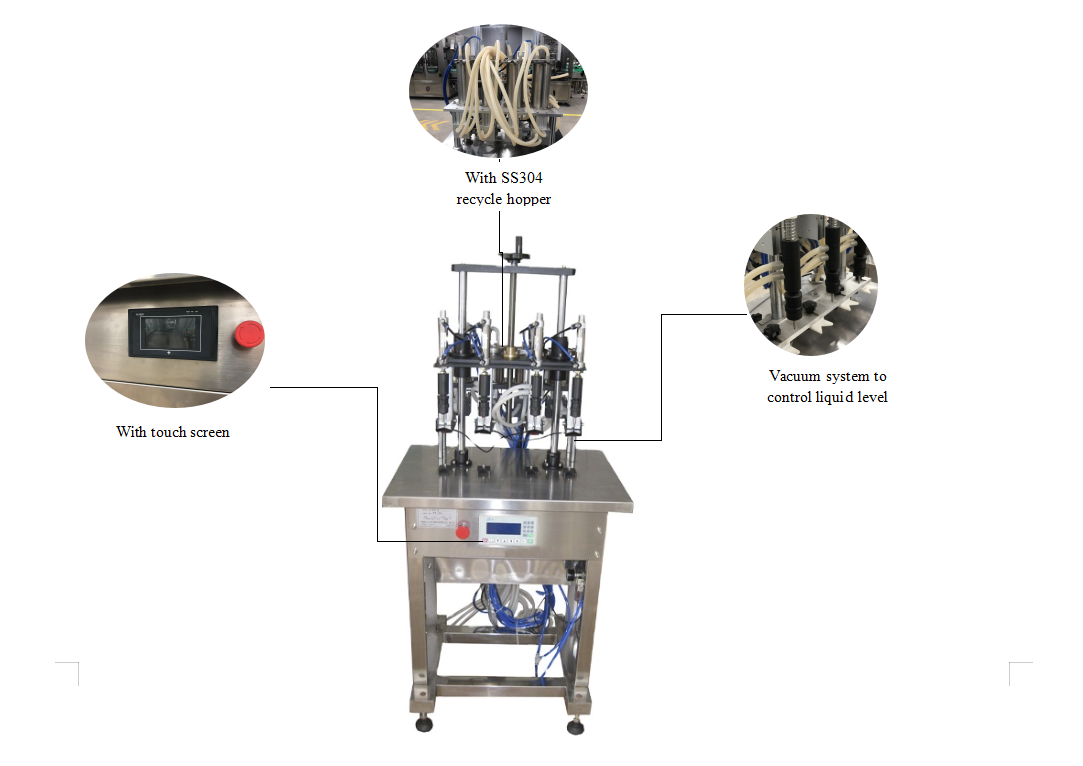

4 heads perfume filling machine

-

Function:

-

filling

-

Bottle type:

-

Unlimited

-

Model Number:

-

YHGz

-

Capacity:

-

20-30bpm

-

Filling range:

-

5-1000ml

-

Filling nozzles:

-

4 Nozzle

-

Air pressure:

-

0.5-0.7 MPA

-

Heating temperature:

-

80 degree max

-

Machine material:

-

Stainless Steel SUS 304/316L

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YUHANG

-

Dimension(L*W*H):

-

500*450*1650mm

-

Weight:

-

40 KG

-

Product name:

-

4 heads perfume filling machine

-

Function:

-

filling

-

Bottle type:

-

Unlimited

-

Model Number:

-

YHGz

-

Capacity:

-

20-30bpm

-

Filling range:

-

5-1000ml

-

Filling nozzles:

-

4 Nozzle

-

Air pressure:

-

0.5-0.7 MPA

-

Heating temperature:

-

80 degree max

-

Machine material:

-

Stainless Steel SUS 304/316L

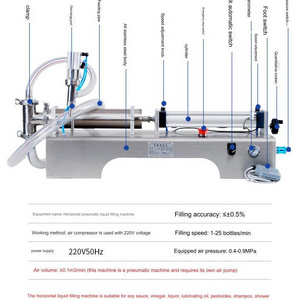

Product Description

automatic perfume filling machine for perfume bottle is used for filling floral water, perfume and other water-based materials. The machine adopts negative pressure and fixed liquid surface type filling. Explosion-proof type products can be provided according to user requirements.

Application

floral water, perfume and other water-based materials. The machine adopts negative pressure and fixed liquid surface type filling. Explosion-proof type products can be provided according to user requirements.

Specification

|

Filling speed

|

1200-3600bottles/H

|

|

Filling precision

|

1.50%

|

|

Dimension

|

L80*W60*H130(cm)

|

|

Machine material

|

Stainless steel

|

|

Total weight

|

60kg

|

|

Filling nozzle diameter

|

1.5mm

|

|

Exhaust volume

|

60L / min

|

|

Compressed air consumption

|

100L / min

|

|

Working pressure of compressed air

|

5kg ~8kg/ cm2

|

Product Features

1. Negative pressure liquid sucking filling. The filling volume is measured according to liquid level.

2. Caster wheels are installed for convenient movement.

3. The parts and table surface that contact the materials are all made of 316L stainless steel, with body material 304 stainless steel

4. Suitable for glass bottles, or plastic bottles whose body will not be easily deformed after vacuum extracting.

5. Convenient adjustment, operation and maintenance.

2. Caster wheels are installed for convenient movement.

3. The parts and table surface that contact the materials are all made of 316L stainless steel, with body material 304 stainless steel

4. Suitable for glass bottles, or plastic bottles whose body will not be easily deformed after vacuum extracting.

5. Convenient adjustment, operation and maintenance.

FAQ

1.What is your delivery time?

Answer: 7-10 days for the in stock machine.And it usually takes around 15-30 days to manufacture the whole production line. For emergent needs of special parts, the process could be shortened.

2.What is the warranty and how is the after-sale service?

Answer: We provide one-year warranty which does not include easily damaged spare parts, such as heaters, belts, etc. Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

3.Can you arrange technicians for overseas debugging?

Answer: Yes, we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

4.Is the machine available with 415V/380V /220V/110V?

Answer: We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

5.Are you a manufacturer or trade company?

Answer: We are a manufacturer in chemical machinery field more than a decade. With experienced engineer and technician team, we can provide the best solution to your requirement. If you are interested, we can arrange factory tour for you.

6.Do you have any certification?

Answer: We are CE and ISO9001 certified company.

Answer: 7-10 days for the in stock machine.And it usually takes around 15-30 days to manufacture the whole production line. For emergent needs of special parts, the process could be shortened.

2.What is the warranty and how is the after-sale service?

Answer: We provide one-year warranty which does not include easily damaged spare parts, such as heaters, belts, etc. Technicians will guide you to install, test machines, and provide free training to your staff in terms of operating and maintaining the machines. Operating manuals will also be sent with machine or by email.

3.Can you arrange technicians for overseas debugging?

Answer: Yes, we can provide services as needed exclude visa fees, round-trip air tickets, and accommodation. We can also arrange your technicians to study in our factory before shipment.

4.Is the machine available with 415V/380V /220V/110V?

Answer: We provide solutions and converter to different power sources and different plug bases for customers from all over the world.

5.Are you a manufacturer or trade company?

Answer: We are a manufacturer in chemical machinery field more than a decade. With experienced engineer and technician team, we can provide the best solution to your requirement. If you are interested, we can arrange factory tour for you.

6.Do you have any certification?

Answer: We are CE and ISO9001 certified company.

Hot Searches