* UL94 V-0 approval.

* Low quality rubber becomes sturdy after 30 days, lose

resilience.

resilience.

|

Items

|

Value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

HAGOIN

|

|

Model Number

|

custom

|

|

Processing Service

|

Moulding

|

|

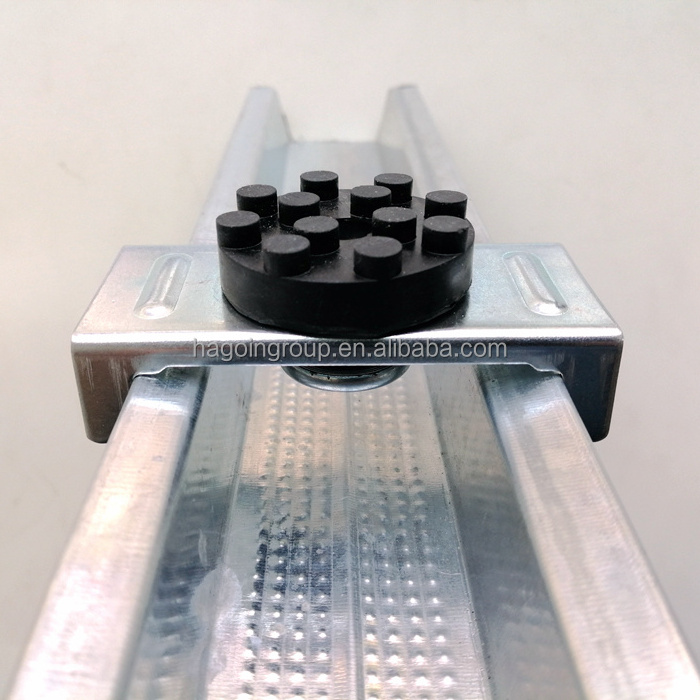

Material

|

resilient rubber

|

|

Size

|

According to the Drawing

|

|

Delivery Time

|

With 15 days

|

|

Packing

|

Plastic bag, nylon bag, carton or according to customer requirement.

|

|

Certificate

|

CE,ISO9001,LFGB, ROHS,

|

|

Features

|

resilient

|

|

Hardness

|

Between 30-90 Shore A

|

|

ODM/OEM

|

Welcome

|